Scanlon

Western Thunderer

The MOK Merchant Navy has absolved itself and passed running trials with flying colours and is on its way for painting.

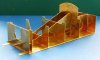

Meanwhile work is progressing on the Crosti 9F with the smokebox, boiler, firebox and running plate all in production. These photos show the etches for the smokebox

and the firebox

The smokebox is an awkward thing to build especially the "wings" but generally this was a straightforward item to construct despite the many parts. The firebox was another story, there are a number of overlays to be inserted inside the main etches. These make forming up the firebox sides and top quite difficult as all are located on the curved sections. The most difficult area is at the mudhole door location at the lower front of the firebox. A lot of metal had to be ground out before the "lump" could be accommodated.

The boiler also has a number of overlays to go inside. To make matters more difficult there are four lower recesses made up of up to four pieces each and they become very difficult to roll to the inside radius of the boiler. This is the current state of the boiler, the slight "dent" in the firebox top will shortly be attended to!

The running plate etch requires modification to accommodate the firebox. Quite a lot of metal has to be removed from what is a vulnerable area, fortunately a template is provided to guide the builder.

Having built another of these locos I knew to allow just a little more space for wiggle room plus the upturn plates that run along the inner edges of the running plates, although these have yet to be fitted. Finally everything just placed in their relevant positions.

More next week

Meanwhile work is progressing on the Crosti 9F with the smokebox, boiler, firebox and running plate all in production. These photos show the etches for the smokebox

and the firebox

The smokebox is an awkward thing to build especially the "wings" but generally this was a straightforward item to construct despite the many parts. The firebox was another story, there are a number of overlays to be inserted inside the main etches. These make forming up the firebox sides and top quite difficult as all are located on the curved sections. The most difficult area is at the mudhole door location at the lower front of the firebox. A lot of metal had to be ground out before the "lump" could be accommodated.

The boiler also has a number of overlays to go inside. To make matters more difficult there are four lower recesses made up of up to four pieces each and they become very difficult to roll to the inside radius of the boiler. This is the current state of the boiler, the slight "dent" in the firebox top will shortly be attended to!

The running plate etch requires modification to accommodate the firebox. Quite a lot of metal has to be removed from what is a vulnerable area, fortunately a template is provided to guide the builder.

Having built another of these locos I knew to allow just a little more space for wiggle room plus the upturn plates that run along the inner edges of the running plates, although these have yet to be fitted. Finally everything just placed in their relevant positions.

More next week

- I was aware of the chassis adjustment when I bought it though.

- I was aware of the chassis adjustment when I bought it though.