Giles

Western Thunderer

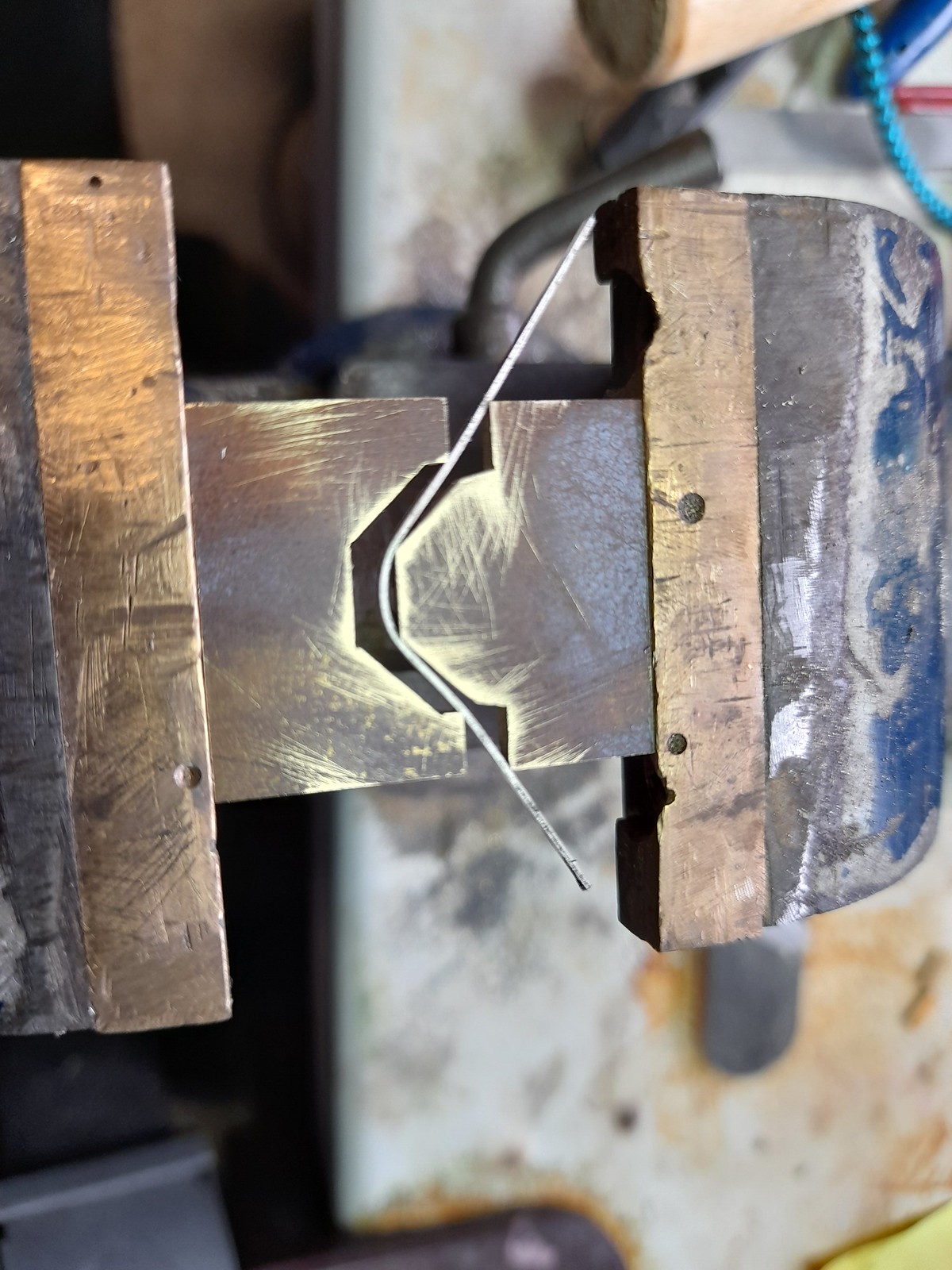

They require more force over a shorter travel, and they dont have the mobility and articulation. I raided Di's workshop to check first! By necessity, their wires are very short, and therefore rather unforgiving - even the large studs you can get. This home-made version is really quite friendly for its purpose!