Lyndhurstman

Western Thunderer

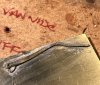

Now that is nice.

Perhaps tinning the relevant shank with as little solder as you can an a light polish? You could gain the odd micron of additional clearance by means of a bit of gentle broach twiddling in the shank. Worth a go?

Adam

Hi Adam,

Thanks! Yes; I was thinking some solder might work, but as I have 24 of these little blighters to do, I'm still trying to find a process that minimises effort and maximises enjoyment - and learning

Hence the wonder regarding plating with NS. There appear to be several YT videos and fora that describe the method, but I'll not make a move into Electric Plating Land (cue Jimmy Hendrix..) until I’m convinced I can do it in safety! As to broaches - again, it's a potential source of fitting freedom... all good stuff to chew over...

Hence the wonder regarding plating with NS. There appear to be several YT videos and fora that describe the method, but I'll not make a move into Electric Plating Land (cue Jimmy Hendrix..) until I’m convinced I can do it in safety! As to broaches - again, it's a potential source of fitting freedom... all good stuff to chew over...Interestingly, in my search for stuff, I came across this:

In the deep and very distant past I remember being toldt,on a school trip around "The Works " at Wolverton that the standards for BR plating was for nickel , copper then nickel , inspection , 2nd Nickel . For Chrome , copper , Nickel , Chrome , inspection, 2nd hrome. Could explain why the handles on 60yr old coaches still have chome on them !

Nickel Plating Brass | Model Engineer

Thanks again

Cheers

Jan

Last edited:

). A few seconds of back and forth is all that’s needed. Any burrs (there will be some) are dealt with using a Swiss file, and the bore cleaned up with a suitable broach. Now it’s just a matter of finding a nice thin glue to hold them in the plastic housing.

). A few seconds of back and forth is all that’s needed. Any burrs (there will be some) are dealt with using a Swiss file, and the bore cleaned up with a suitable broach. Now it’s just a matter of finding a nice thin glue to hold them in the plastic housing.

I suppose a lump of casting was too much to accommodate in such a modern design! Still, even at this late stage, it’s the little discoveries like this that give me pleasure..

I suppose a lump of casting was too much to accommodate in such a modern design! Still, even at this late stage, it’s the little discoveries like this that give me pleasure..