Slowly slowly catchy monkey.....

A week I'd rather forget, a whole week on just the boiler and firebox and still no where near finished.

The boiler was pre-rolled, badly (I understand why it's shipped rolled, if flat, it wouldn't fit in the box) and such thick gauge it's near impossible to straighten or work with, in hindsight I should of just flattened it as best possible and copied it to thinner material and then binned it; but it ended up reasonably good in the end.

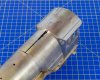

One hurdle was fitting the speaker, or as I'm a maintenance engineer, being able to get it out in the future if it fails, thus a tube was formed inside the boiler to hold the speaker.

View attachment 118485

The copper wire ring prevents it falling into the smokebox, it'll be held in place from the rear with the weight and some sort of devised bracket to hold that in place.

Having a big hole in the forming rings does mean you loose the alignment holes which can be used for screws to hold it altogether for soldering up, thus another copper wire ring was fitted to the smoke box rear and aligns with the boiler front. Each former ring is set back from the wrapper edge anyway, so the wire ring just sits nicely and equally in each end.

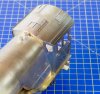

Progress to date.

View attachment 118486

View attachment 118487

View attachment 118488

View attachment 118489

The white metal is just placed on to give an idea of how the whole engine looks.

The firebox was time consuming, I actually built the rolling chassis quicker

and it still has it's niggles, there are nice brass castings for the firebox front corners, but as can be clearly seen, they're too short.

If you raise the footplate up by adjusting the swept bends then it'll be higher than the front and tip forward.

If you remove some of the firebox base then the crown will be too low in relation to the cab front. A big blob of Milliput will be wedged in there and then blended in, not looking forward to that at all.

The wash out holes are in the wrong place, the instructions tell you this so they have to be plugged and new ones drilled 5 mm lower.

There are no hand rail knob holes in any of the kettle bits, cheers, thanks for that extra work load

However, the biggest issue is the profile of the firebox wrapper at the rear, woefully wrong and after many days of teasing, filling and adding thin fillets and wedges to close up the gaps you realise it's also a whopping 5 mm too narrow at the shoulder. The cladding should just butt up to the inside edge of the spectacle window frames.

Of course there's no way of knowing that until it's virtually finished and all the formers and joints are soldered up.

There are three options going forward;

1: Leave it as it is and given the time expenditure already involved accept it and live with it. This fits the build out of the box criteria.

2: Totally remove the wrapper and start with a new one and then add back all the castings and details, that'll add a week onto the build easily.

3: Slit the top of the firebox from front to rear, widen at the rear the require amount and then plug the slot in the top with a brass wedge and make good. Once the top is widened it'll then create a gap down the sloped sides to the base, that'll have to be filled as well.

Time for a stiff drink I think.

and it still has it's niggles, there are nice brass castings for the firebox front corners, but as can be clearly seen, they're too short.

and it still has it's niggles, there are nice brass castings for the firebox front corners, but as can be clearly seen, they're too short.

as regards to the errors, you've been lucky, there are lots of errors in these parts, not so bad that you cannot make do, but bad enough to keep on stumbling over and wasting time correcting, the tender suffered the same in some areas. I've attached a couple of pictures below to compare with Richards screen grab, once seen it cannot be unseen.

as regards to the errors, you've been lucky, there are lots of errors in these parts, not so bad that you cannot make do, but bad enough to keep on stumbling over and wasting time correcting, the tender suffered the same in some areas. I've attached a couple of pictures below to compare with Richards screen grab, once seen it cannot be unseen.

scraped off the pavement".

scraped off the pavement".