Moving on below decks the next 'large' object to make up/fabricate is the firebox base and ash pan.

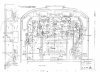

The kit gives you two parts, the sides and floor and the front, there is no rear. The sides have a dog leg etch to allow you to fold the foundation (mud) ring and some generic rivet half etch dimples on the inside, the front has none.

The floor is also solid and has two folds up brackets to support the pipes that run to the rear engine, we need these for later but note the overly generous etched space around them, this'll bit you on the bum later if you go for the more authentic set up.

The etches are basically both the lower firebox and ash pan in one and as such do not really do both justice, it's a compromise and it'll show in the end.

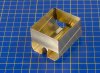

I'd already decided that my firebox base will be a 3D prints with nice big domed stay bolt heads and lapped plate work so it was a simple case to fold up the pan with out the dog leg step to replicate the mud ring, I also took the extensions fore and aft of the firebox base off as well, they wil just get in the way of the print.

The ash pan has a chamfered lower outer corner and looking at the etch above it's clear the outline is not going to produce a flat edge for the doors to close to. you basically need to trim back the flat edge between the two parallel etch lines and make it angled.

See red lines below.

If you make it a straight cut as shown in green then you will end up with gaps between the pan sides/floor and doors at the point circled in green. The easiest way is to fold it up and trim in place whilst offering up a flat sheet of brass until you get the correct angles.

The front etch also includes the doors....sort of, they're just too short and you'll be left with a gap at the bottom I'm afraid. i'd already decide to have partially open damper doors so trimmed the front sheet back accordingly.

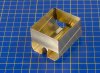

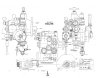

Okay, bit of a big jump picture wise to the completed unit, the shell anyway.

The yarn here is to attach your shortened front face (after first tracing it for a new rear face) to the fold up sides and base and then the new rear face. Once you have the front and rear faces in place you need to fabricate the tunnel, it's not as simple as it looks as the front and rear edges slope backward to mimic the sides but with care they can be trimmed, test fitted, trimmed and finally fitted into place.

At this point the floor is still solid but we need to break out the pipe brackets as we'll use them later, I'm not sure if those are on the real engine, but they are important on the model as they support the pipework in a hidden way which supports all the visible pipework ahead of the ash pan.

A higher angle view shows where the pipe brackets were taken out and the large etch gap around them can be seen as holes in the floor alongside the tunnel base. It's those two long thin sausage shapes, mine are now covered...see later...but if not you'd see the blue cutting mat below.

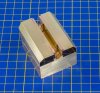

Having secured the tunnel it's time to flip it over and cut away the material down the middle, a slitting disc makes light work of it and then the pipe brackets were trimmed and dropped into the tunnel space.

Forgive the salmon pink metal, left it in the Limelite too long, it cleans off though with a fibre brush. To cover the gaps left from the pipe brackets I simply added some 1.0 x 2.0 mm angle I'm not sure if the real engine has an external angle plate here, photos do show some sort of angled fixing, probably internal but it sort of looks external as well, it's a 50/50 call really. I've evoked rule#1 and as this is a late BR engine they have fitted two new external angles due to the originals rotting away; plus they cover the holes rather nicely.

The alternative would of been an all new scratch sides and base, easy to do as an etch but this way uses most of the original and provides a strong and square assembly, all be it with some extra leg work.

Whatever is there is cut back at the front and rear, the small gap is for a transverse strap that bridges across the front and rear edges of the ash pan base, these are brake rigging safety straps to prevent it dropping on the P' way in case of failure. The straps will be added later with the other details.

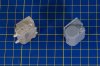

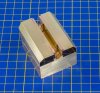

A quick check on the engine.

I was going to bemoan the big fat F etched on the brake hanger, surely it would of been better on the upper face and thus hidden once the bracket is fitted, it does at least tell me which is the front, which is more than I can say for the ash pan as I've placed it on the frames back to front

The irony is not lost on me, but at least we can now see the new rear face from the clean side

.

The next step is to make up from scrap etch the new mud ring and fit that to the ash pan core we now have, there are also large double row riveted strengthening plates that run front to rear on the cambered ash pan faces on BR engines, and, I need to work out some sort of fixing method, probably a few discreet 12BA screws somewhere; there are no guides or slots and tabs to fit the kit assembly so it's a trial by fire and alignment with the upper works really.

) the more fade you will get as will spraying across the sausage rather than up to it.

) the more fade you will get as will spraying across the sausage rather than up to it.

. Luckily, the chemical company I worked for had it's own fully equipped engineering workshop for maintenance of the production facility and one of the engineers very kindly drilled them outfor me on one of the vertical machines. The slidebars and crossheads had to be fabricated from etched parts as well, but with none of the aids to lining up that are the norm theses days or better still good quality cast NS ones. Something of a challenge for a third kit but the JM kits did build up nicely if you put the effort in. Your 1st print is already streets ahead of the kit ones.

. Luckily, the chemical company I worked for had it's own fully equipped engineering workshop for maintenance of the production facility and one of the engineers very kindly drilled them outfor me on one of the vertical machines. The slidebars and crossheads had to be fabricated from etched parts as well, but with none of the aids to lining up that are the norm theses days or better still good quality cast NS ones. Something of a challenge for a third kit but the JM kits did build up nicely if you put the effort in. Your 1st print is already streets ahead of the kit ones.

It built up in to a really nice model, tube boiler included, but there are, of course, no cast cylinders to wrangle.

It built up in to a really nice model, tube boiler included, but there are, of course, no cast cylinders to wrangle. it's not even the correct size or profile

it's not even the correct size or profile

.

.