mickoo

Western Thunderer

Mid week update on the Garratt.

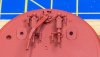

First off the ash pan saga, new mud ring fitted and then a 3D print of the ash pan made up and fitted.

There are no fixings in the kit so I simply added two plates and fixed screws up from below, the nuts are important, they stop the screws falling out and space the ashpan the correct distance from the bed plate.

And from below.

CCU visited when I cut back the mud ring at the front So I'm going to have to graft a small strip along the front and blend it in, not too hard, just annoying. It also looks like the print has got damaged around the corner washout plug bosses, eventually some square rod will go in these to replicate the plugs.

So I'm going to have to graft a small strip along the front and blend it in, not too hard, just annoying. It also looks like the print has got damaged around the corner washout plug bosses, eventually some square rod will go in these to replicate the plugs.

Fitted to the boiler bed plate. The extra spacing means that the print no longer buts up to the floor sheet, I'll make a new print with higher front and rear to seam the gaps. In reality I think there should be cross stretchers here so I might add them instead.

The damper doors are going on the etch I'm working up, as will the double row riveted strengthening straps, much easier to etch these than cut by hand.

I'm not happy with the large flat plate that supports the brake trunnion hanger, it's coming out and four oblong holes with rounded corners are going in, this area closely matches the SAR GG engine so I'll replicate that set up.

Right way up, I need to adjust the stay bolt head spacing on the front corners in the vertical plane, there should be five not three visible on the side plate.

Moving on to the cab, I mentioned the kit backhead was not the right profile, so a new one in 3D was worked up, just a first off test print. I added the regulator stuffing gland as part of the main print and now need to work out which fittings I'm going to use, then add any holes or plate work to match.

Finally we come to the boiler bed plate pedestal bearings, those in the kit are just a functional bock of white metal, which kind of leaves the ends rather bare. Whilst you cannot see all of the ends, you can see enough to be offended.

Using the SAR GG casting as a rough guide I've made a new printed cast block, I've no idea if it is 100% authentic but it looks a bit better. It's only a basic test print to check fitting and needs a few tweaks here and there as well as some bolt head detail and such; it'll probably need another tweak anyway once we come to fitting to the engines as clearances are tight in here.

First off the ash pan saga, new mud ring fitted and then a 3D print of the ash pan made up and fitted.

There are no fixings in the kit so I simply added two plates and fixed screws up from below, the nuts are important, they stop the screws falling out and space the ashpan the correct distance from the bed plate.

And from below.

CCU visited when I cut back the mud ring at the front

So I'm going to have to graft a small strip along the front and blend it in, not too hard, just annoying. It also looks like the print has got damaged around the corner washout plug bosses, eventually some square rod will go in these to replicate the plugs.

So I'm going to have to graft a small strip along the front and blend it in, not too hard, just annoying. It also looks like the print has got damaged around the corner washout plug bosses, eventually some square rod will go in these to replicate the plugs.Fitted to the boiler bed plate. The extra spacing means that the print no longer buts up to the floor sheet, I'll make a new print with higher front and rear to seam the gaps. In reality I think there should be cross stretchers here so I might add them instead.

The damper doors are going on the etch I'm working up, as will the double row riveted strengthening straps, much easier to etch these than cut by hand.

I'm not happy with the large flat plate that supports the brake trunnion hanger, it's coming out and four oblong holes with rounded corners are going in, this area closely matches the SAR GG engine so I'll replicate that set up.

Right way up, I need to adjust the stay bolt head spacing on the front corners in the vertical plane, there should be five not three visible on the side plate.

Moving on to the cab, I mentioned the kit backhead was not the right profile, so a new one in 3D was worked up, just a first off test print. I added the regulator stuffing gland as part of the main print and now need to work out which fittings I'm going to use, then add any holes or plate work to match.

Finally we come to the boiler bed plate pedestal bearings, those in the kit are just a functional bock of white metal, which kind of leaves the ends rather bare. Whilst you cannot see all of the ends, you can see enough to be offended.

Using the SAR GG casting as a rough guide I've made a new printed cast block, I've no idea if it is 100% authentic but it looks a bit better. It's only a basic test print to check fitting and needs a few tweaks here and there as well as some bolt head detail and such; it'll probably need another tweak anyway once we come to fitting to the engines as clearances are tight in here.

Last edited:

so rather than lead the horse to water, I'm just going to go drink myself, no point keeping the horse if it's just become a burden.

so rather than lead the horse to water, I'm just going to go drink myself, no point keeping the horse if it's just become a burden.