mickoo

Western Thunderer

Well there's a loaded questionVery impressive - do you think that the 3D print will be able to make the flange thin enough to match? It looks awfully thin to me. To match the fullsize proportions do you think a 3D print doors and lugs on a nickel-silver disc give a better representation?

Technically yes, in theory you can print as thin as 0.01 mm, in practice no, especially a large area like that.

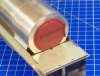

The AWS/steam brake bracket on the B1 test was 0.5 mm thick and it's free standing so that thickness is certainly possible but again, give the large surface area the peel forces would distort such a thin edge.

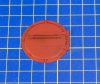

The trick is to design the piece so that it can be printed and then post processed to give the desired result, in short, we make a sacrificial rim around the base of the door, in this case 1.0 mm thick, once printed and cured under UV we then sand that sacrificial edge back to the thickness we require, or as far as your cajones will let you.

It just requires some forward thinking into the design of the door so that you can achieve the final result.

You could have a metal disc and print as you suggest, but then the lugs would be very fragile spigots sticking out of the door, same for the hinges, there is a risk that these small fragile parts would distort during the print process, meaning you'd need to add a sacrificial edge to them which when removed would probably break them.

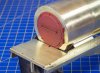

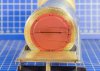

I tried that back last year with the gauge 1 Baureihe 50 smokebox door. The initial print had separate lugs and hinges, they did not fair well, even in gauge 1.

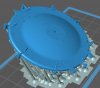

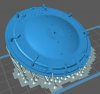

Further tests added the smokebox door flange sealing plate and eventually the whole smokebox front face, much stronger.

The parts failed for other reasons, lack of understanding of the material, supports and orientation in the printer, but most of all, lack of understanding how the print process actually works and how to design parts that will (on the whole) consistently print.

You only get that from doing it, again and again and again, over and over until you begin to understand what your doing. That's hard when something like the Br50 door in gauge 1 can take 4-5 hrs to print.

You also get it from reading forum after forum, post after post, trying this setting and that setting, it's not an easy process like CAD where you draw lines, join them up and then fill.

Really successful print gurus tend to be rather tight lipped about specific setups and tricks of the trade, I can understand why, it's like trying to build a 1000 piece jigsaw, but first you have to find all the pieces, as the box is empty.

Wargaming or mini/figurine forums are the best, what some of those guys are doing is mind blowing, but all of them are...for want of a better phrase....free style, what we're doing for models is engineering and SLA printers are not the best printer to achieve nice crisp engineered shapes. Excellent for middle earth Dwarfs and haunted forest Elves, crap at making a simple perfectly square dice.

I do need to go back to the Br50 project with the knowledge I have now, I think I'd get better results.

Last edited:

so kind of making it up as I go along; it's going to be, how shall we say? Fun

so kind of making it up as I go along; it's going to be, how shall we say? Fun