A week has passed and the nice clean chassis is taking it's toll, grubby is as grubby does

Moving at glacial speed now, two steps forward, one back, the 4F lumbers along. If you want inside motion in a 4F then don't start here, or there or anywhere, it's a nightmare. It's not the kits fault, it's simply not designed to accommodate inside motion. I opted for the Laurie Griffin inside motion set, overall it seem good but has to be compromised to fit inside narrower frames, those compromises lead to others and soon it's a whirl pool of head bending solutions to overcome each in a steady stream changes.

In all fairness, if I had known inside motion was required at the start then I would of made new frames, it would of been faster and cheaper, none the less, wacka mole has been the order of the last two weeks.

The biggest stumbling block is the cylinder block, it has to squeeze in past the front stay (heavily hacked) and the leading horn guides, the piston and valve centres have to be set to align with the inside crank, but here in lines a hidden bear trap, the 4F valves do not follow a logical straight line from crank to valve, there are offset links and swinging arms to add to your woes.

Once the cylinder block was finalised then I could work up the motion bracket, the kit one is that square sheet with two square holes, the last image is the new etch sheet showing the new bracket and all the additional links you need as well as the LG set. You see the LG set is designed for engines with valves below the pistons, the 4F has them above, thus the drive has to be cranked up from below the drive line to above.

I'll be honest, I'll be staggered if all those bits fit and align on the first hit.

On a positive note, the springs inside the drain cocks actually printed fine and the little slots in the valve stem gland show the brass insert lovely. The brass insert allows the valve rod to function and not wear the 3D print. The piston gland is part of the slide bar assembly and has a spigot that fits into the print.

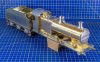

Right way up, it actually looks cleaner than it really is. There's a couple of micro plunger pick ups buried inside the cylinder block, it's impossible to get the cables from there to the motor down the inside of the frames. There's two choices, opt for US style pick ups, or, run a cable with two plugs at each end through the boiler from smokebox to firebox, I opted for the second one and I've some smaller plugs in the post from a very nice chap, you know who you are

View attachment 132508

View attachment 132508

From below, now that the ash pan is finally fitted I can add the steam lines to the rear sanders and feed them up inside the frames ans secure them.

View attachment 132509

There's a small cut out in the rear of the ashpan to accommodate the motor worm.

View attachment 132510

The cylinder casting and the kit offering for the motion bracket. The brass inserts for the valve guides will be fitted after paint, that way the little slots in the casting will highlight the brass effect, no point modelling the slots if they're all blended in as one colour.

View attachment 132511

The new etch sheet with all the extras need to compliment the LG inside motion kit, as well as a correctly shaped motion bracket.

View attachment 132507

Time for some beer.....

A new 3D print with brass fittings shall be required, I shall also be adding a 3D cylinder block and try to fill in all the gaps around the ashpan, the frames are.....how shall we say.....barren but functional

A new 3D print with brass fittings shall be required, I shall also be adding a 3D cylinder block and try to fill in all the gaps around the ashpan, the frames are.....how shall we say.....barren but functional

3924_K&WVR_010803_Valve rocker

3924_K&WVR_010803_Valve rocker