You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm Mickoo's Commercial Workbench

- Thread starter mickoo

- Start date

mickoo

Western Thunderer

You're a wuffian and a Wabscallion....I shall have my Centurions fwhow you woughly to the ground

Col.

mickoo

Western Thunderer

Cheers, the pictures do not really do it justice; I really struggled to get decent photos, almost too bright and there's a terrible colour cast.Fab-u-lous

Gary

The model just soaks up light so I might try less is more and see how that goes, I did some photos for a couple of Nicks models as well and they were much better. My initial thoughts are that they were smaller models and thus less back ground to reflect the light which led the camera to take a better more balanced image.

mickoo

Western Thunderer

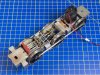

Small update, RH side internal valve gear set up.

Unlike the 4F the 47xx is designed to take inside valve gear so it is very easy to add even after paint (late requirement from customer), requiring only one extra shaft to be passed across the frames and two pins at the rocking links up front.

Does anyone know if the inside valve gear was painted or left bright on early GWR engines; I've seen lots of preserved engines with all red valve gear but that may be a modern thing, besides it looks kind of nice in bright work.

Unlike the 4F the 47xx is designed to take inside valve gear so it is very easy to add even after paint (late requirement from customer), requiring only one extra shaft to be passed across the frames and two pins at the rocking links up front.

Does anyone know if the inside valve gear was painted or left bright on early GWR engines; I've seen lots of preserved engines with all red valve gear but that may be a modern thing, besides it looks kind of nice in bright work.

mickoo

Western Thunderer

Martyn I think the slip eccentrics and axle would be red but the actual valve gear could go either way in my mind, especially back in 1923 when this is modeled, they would have like nicely polished gear in there I think.Hi Mick,

Not sure if it’s left bright or not, but are you using rivets on those joints ? And if so who’s are they ?

Cheers,

Martyn.

Yes all the joints are riveted except the top lifting link/reversing crank joint which is nickel silver wire, they should be steel in the kit but none were present so I made my own, they may be a little over scale but buried deep in the engine I hope they're not overly offensive.

I simply turned down the heads on 14BA cheese head bolts, I only had brass in the pot so brass it was, the heads ended up being about 0.5 mm thick, 0.3 or 0.2 would have been better and maybe slightly smaller diameter.

By not taking the cusp of the fixing side you can sort of screw them in by finger and add a small dab of solder, clean up and file to leave a small stub on the back side.

SimonT

Western Thunderer

Mick,

as you won't have a copy of Great Western Way, I have referred to mine. It is considered the authority on all things decorative for the GWR.

From 1906 the spec called for "all below the footplate to be black". "All motion to be polished steel", although motion is not defined.

Move forward to 1923 and it is "all below the footplate to be black". Further, "The valve gear, piston rod, crosshead, motion bars, connecting and coupling rods were bright steel".

Move forward to 1945 and we get the items in black above the footplate specified in great detail and then "and the footpate and all below in black". Later the paragraph discusses numberplates and panniers and side tanks. And then we get "Buffer beams and casings, the inside frames between the smokebox and firebox and the eccentric rods and crank axle were red."

Which leaves open the question of weigh shafts, lifting links, motion brackets between the frames, vac pumps and many other items. Oh, not forget what period it's in and if it is a 47 that stayed in green during the black period for all except express passenger locos.

Hope this helps.

Simon,

PS Nice way of building the valve gear. I may need details and photos.

as you won't have a copy of Great Western Way, I have referred to mine. It is considered the authority on all things decorative for the GWR.

From 1906 the spec called for "all below the footplate to be black". "All motion to be polished steel", although motion is not defined.

Move forward to 1923 and it is "all below the footplate to be black". Further, "The valve gear, piston rod, crosshead, motion bars, connecting and coupling rods were bright steel".

Move forward to 1945 and we get the items in black above the footplate specified in great detail and then "and the footpate and all below in black". Later the paragraph discusses numberplates and panniers and side tanks. And then we get "Buffer beams and casings, the inside frames between the smokebox and firebox and the eccentric rods and crank axle were red."

Which leaves open the question of weigh shafts, lifting links, motion brackets between the frames, vac pumps and many other items. Oh, not forget what period it's in and if it is a 47 that stayed in green during the black period for all except express passenger locos.

Hope this helps.

Simon,

PS Nice way of building the valve gear. I may need details and photos.

Dog Star

Western Thunderer

Not the valve rods on the outside of the frame... and probably not the rocker arms....so all red then, shame as bright valve gear looks nice.

mickoo

Western Thunderer

Having read Ian's information a little more, the inside frame red is not the same as the buffer beam red, it is in fact Venetian red or red oxide to the rest of the modern world.

It seems and odd colour to choose and most people paint the inside the same colour as the buffer beams.

It seems and odd colour to choose and most people paint the inside the same colour as the buffer beams.

3 LINK

Western Thunderer

Yes all the joints are riveted except the top lifting link/reversing crank joint which is nickel silver wire, they should be steel in the kit but none were present so I made my own, they may be a little over scale but buried deep in the engine I hope they're not overly offensive.

I simply turned down the heads on 14BA cheese head bolts, I only had brass in the pot so brass it was, the heads ended up being about 0.5 mm thick, 0.3 or 0.2 would have been better and maybe slightly smaller diameter.

By not taking the cusp of the fixing side you can sort of screw them in by finger and add a small dab of solder, clean up and file to leave a small stub on the back side.

Thanks for the info Mick regarding the 14 BA bolts, that could come in handy for my next build a Finney 2251. Especially with this class of loco as the inside motion is quite exposed.

Cheers,

Martyn.

mickoo

Western Thunderer

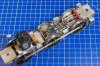

All but finished the Finney7 47xx, the rest of the inside motion was built up.

Painted and inserted into the frames.

You need to space the link away from the bracket about 1.5 mm, I simply added some tube over the screw to pack it out.

The inside motion needs a coat of satin varnish to bring it to the same level of shine as the rest of the interior, I'll let the paint dry for several days before doing that, so excuse the gloss matt mixture of surfaces.

The only thing left to do is the insulated bush on the engine draw bar fixing screw and spectacle plate glazing. I hate glazing, more so where there is no rebate or recess and it has to be cut exactly to size.

I've already decided that if another ever passes this way, then I will get some new glazing frames etched up that have a recess to resolve this very problem. You still have to be accurate with your cutting but now you have a flat surface to mount to, as opposed to edge viz edge.

I think I need to paint the reversing lever red and add a metal handle, need to check on that in due course.

Painted and inserted into the frames.

You need to space the link away from the bracket about 1.5 mm, I simply added some tube over the screw to pack it out.

The inside motion needs a coat of satin varnish to bring it to the same level of shine as the rest of the interior, I'll let the paint dry for several days before doing that, so excuse the gloss matt mixture of surfaces.

The only thing left to do is the insulated bush on the engine draw bar fixing screw and spectacle plate glazing. I hate glazing, more so where there is no rebate or recess and it has to be cut exactly to size.

I've already decided that if another ever passes this way, then I will get some new glazing frames etched up that have a recess to resolve this very problem. You still have to be accurate with your cutting but now you have a flat surface to mount to, as opposed to edge viz edge.

I think I need to paint the reversing lever red and add a metal handle, need to check on that in due course.

mickoo

Western Thunderer

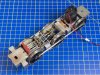

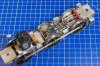

Finally! Inside motion all fitted to the 4F.

It needs a lot of running in and there is a little tight spot that needs chasing down, plus the right hand valve rod has a little kick as the pin in the expansion link is a little loose....read cast expansion link slot too large, a poke with some suitable implements will solve that.

It's a real mish mash of parts, none (other than the new motion etched bits) is designed for this engine, it'd make any East end chop shop boys proud

I do need to rejig the cylinder block, no matter how it was cut and shut the narrow frames really hampered the internals, along with castings just too fat to fit in there, consequently the valve linkages and alignment is slightly out, each needs moving onward by 0.75 mm to line up with the motion.

I had to loose the inner lifting links, there just isn't room in there and the expansion link is the wrong type for this engine with only one link pivot point, there should be two, one each side.

Apologies for the shaky video, it actually runs better on the track, something I find with most engines actually.

New motion bracket and valve linkages.

All fitted up.

It needs a lot of running in and there is a little tight spot that needs chasing down, plus the right hand valve rod has a little kick as the pin in the expansion link is a little loose....read cast expansion link slot too large, a poke with some suitable implements will solve that.

It's a real mish mash of parts, none (other than the new motion etched bits) is designed for this engine, it'd make any East end chop shop boys proud

I do need to rejig the cylinder block, no matter how it was cut and shut the narrow frames really hampered the internals, along with castings just too fat to fit in there, consequently the valve linkages and alignment is slightly out, each needs moving onward by 0.75 mm to line up with the motion.

I had to loose the inner lifting links, there just isn't room in there and the expansion link is the wrong type for this engine with only one link pivot point, there should be two, one each side.

Apologies for the shaky video, it actually runs better on the track, something I find with most engines actually.

New motion bracket and valve linkages.

All fitted up.

dibateg

Western Thunderer

Very neat Mick.

Is the slidebar assembly removable? I normally make the valve gear so that it can be split at the expansion links. The J6 is very similar, except that the the rocker arms are split across a shaft because the valves are wider apart. I've not worked out a way of splitting it, so I'm making it so that it will come apart... It's all very tight and I'll have to scratch up some of it I think.

Cheers

Tony

Is the slidebar assembly removable? I normally make the valve gear so that it can be split at the expansion links. The J6 is very similar, except that the the rocker arms are split across a shaft because the valves are wider apart. I've not worked out a way of splitting it, so I'm making it so that it will come apart... It's all very tight and I'll have to scratch up some of it I think.

Cheers

Tony

Ian@StEnochs

Western Thunderer

Nice work Mick, The wheels always kick a bit if you run them in the air! The rail keeps them in line.

Ian.

Ian.