Although this week is likely to have a couple of Life Interruptions, I wanted to try and make some progress on this job.

Specifically, work on the drawbar areas. First, I did a sketch so I could work out what sort of gubbins was going on, and where it went. Inevitably, this area is going to be somewhat simplified, but I want to attempt to replicate something that looked like the air pipe runs from the control pipes under the buffers.

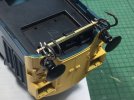

One point was how to attach the cast pipes from JLTRT/MM1. On the model, Heljan give you moulded plastic jobs that fit directly into moulded holes in the lower edge of the body moulding. That wasn’t quite going to work for what I had in mind, and modifying the castings to fit the same way wasn’t going to be easy. I decided some kind of plate would work, onto which I could fit some wire to represent the pipe runs, as well as mount the dangly pipes. After some consideration, I chose some brass 3mm angle section and modified some of it like the picture. The slot in the centre fits around the Heljan lump that represents the coupling bang plate. The holes at the ends are offset slightly, to match the real hoses.

The brass hoses still need some adjustment, essentially carefully straightening the right-angles in the pipework, before they can be fitted. After a bit of a fiddle, this is what I ended up with.

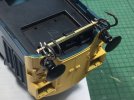

Here we are popped into place. I find I will need to add a little packing so the assembly is clear of the bodywork properly, but that’s not too bad. Happy with that, so the next job is to arrange something to simulate the pipe runs, and add a replacement coupling bang plate as the original is now covered by the angle! I’ll also tidy the hoses where they protrude through the angle.