There has been much needed progress on these coaches in the past couple of days.

Happy that the varnish was quite tough enough to withstand handling, I set about fitting interiors. You may recall the kits appear to have shipped with wood, planed to a seat profile, which was intended to be cut to length. Well, I found, rather late, of the four lengths I had in the boxes there were only two pairs of each - and each pair was a different profile! A quick rummage around the various storage areas and I located another pair of strips near enough the same profile, and set about making them fit.

Being non-corridor stock, I needed to cut compartment walls. I found a single brass one in the box - there may have been many more originally, but who knows where they ended up before the kits were sold on - which I turned into a template to let me mark out styrene sheet.

The shape of the compartments is only rough. They will be finagled into the body shells, and the precise shape is not critical as they are held in place by the seating.

A few minutes with the razor saw, and most of the four strips had been chopped into 60mm lengths for the trailer coach. You can see the different profiles here, with the deeper headrest on the left. Worryingly, this left insufficient to fit out the driving trailer.

Back to the storage areas to see what could be found.

Meanwhile, the compartments were glued to the seat strips. Some kind of plastic solvent was deemed sufficient for this. Once things had set enough, stray edges were sanded back, and things were test fitted into the body shell.

The sides of the coach needed to be gently held open to let the seat assemblies drop in. Was I glad I hadn't spent time adding more bracing struts along the bottom! Some hackery was required to clear fixing nuts in each end compartment, and some adjustment was required to fit each set of seats in their places. Once I was happy, I numbered the base of each seat assembly to identify the location in the coach for later refitting.

Each seat had the printed interior sheet fixed in place. I used SprayMount for convenience. I have a track record of using this contact adhesive for such jobs, and I've found it goes off with sufficient grip after soaking into the wood and paper to not flake away over time. The paper inserts were slightly short in places, and even after some more fettling for fit, I felt it safest to daub some paint over the plain wood to disguise it when in the coach itself.

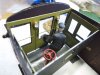

One of the trial fittings, and things are looking pretty good. Those seats that are not a tight fit at this stage were given a dob of glue to fix them to the styrene floor sheet. I haven't fitted the advertisements yet, because to be quite honest I'm not sure you can even see them with the roof on. This matter is currently under consideration.

Here is the roof in place, and it all looks rather smart - aside from the squiffy paint job.

So, that's the trailer coach. What about the driving trailer? Having run short of suitable wooden seating, I had been foraging in the various stores for some alternatives. I dimly recalled a set of Cavalier plastic seating strips, and eventually I found them. (Cavalier Coaches General Coach Plastic Seating Strip, C-G14, 1200mm per pack.)

They were pretty much ideal for the job, almost matching the wooden section for profile. Obviously, it wouldn't work to mix and match wood and plastic in the same coach, so the driving trailer was chosen for the plastic variant.

Much the same procedure was done with the compartment sections, seats glued in place and so on. This is the trial fitting, and you can see the seats have been scored. This is to give whichever adhesive I use for fitting the interior sheets some sort of key to hang on to.

I wanted to fit the interiors before I applied the transfers. Glazing will be left until the last, as will fitting the passengers. I also have to construct the driving cab, which I might tackle tomorrow for a bit of light relief!

The white lines are indian ink applied via a 0.25mm Rötring Rapidograph.

The white lines are indian ink applied via a 0.25mm Rötring Rapidograph.

Back to the storage areas to see what could be found.

Back to the storage areas to see what could be found.