Dash 8-40B

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

P48 for Cotton Belt: Roster addition SW1200

- Thread starter Yorkshire Dave

- Start date

Threadmarks

View all 38 threadmarks

Reader mode

Reader mode

Recent threadmarks

GE70T GE70T GE70T GE70T GE70T U23B U23B SW1200

Dash 8-40B

Yorkshire Dave

Western Thunderer

Today......

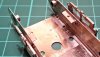

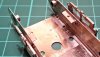

........was spent making these brackets from brass - for the truck bolster.

They are to try and hide the area between the highlighted section on the truck and the bolster.

It looks okay in the photo but the highlighted section is rather 2D and really needs to be 3D, however, it is a rather complex shape. Just need to work out how to make this. Below is one of Mickoo's photos of the area

This is on the geared side of the truck. As the Atlas frame is rather wide I've mounted the brackets temporarily on a block behind the frame. In reality it is bolted to the frame.

........was spent making these brackets from brass - for the truck bolster.

They are to try and hide the area between the highlighted section on the truck and the bolster.

It looks okay in the photo but the highlighted section is rather 2D and really needs to be 3D, however, it is a rather complex shape. Just need to work out how to make this. Below is one of Mickoo's photos of the area

This is on the geared side of the truck. As the Atlas frame is rather wide I've mounted the brackets temporarily on a block behind the frame. In reality it is bolted to the frame.

Big Train James

Western Thunderer

3d model and print all the wayIt looks okay in the photo but the highlighted section is rather 2D and really needs to be 3D, however, it is a rather complex shape. Just need to work out how to make this.

. Just need data.

. Just need data.Steph Dale

Western Thunderer

Haha! That's just what I said!3d model and print all the way. Just need data.

Steph

GE 70T

Yorkshire Dave

Western Thunderer

This brass kit was purchased at Telford earlier this year and although the SP had some they were the later phase variant with different louvre positions. This kit represents the first phase of production.

It is designed to use Slaters lowmac wheels - but not for me though as this will be built to P48 track standards.

So having robbed these insulated 33'' wheels from some Northwest Short Line freight car wheelsets I set about making axles for P48 gauge.

Not bothering to follow convention to use steel, and not having a lathe to turn any, I used what I had in stock i.e. brass tube. I proceeded to make up the axles up from sleeved brass tube to fit standard 1/8'' top had bearing and accept the insulated wheels. Four axles were made and during the process I ran out of 1/8'' brass tube so one axle has an aluminium tube - gosh shock horror . The outer sleeve allows the wheels to be pressed on to P48 track gauge.

. The outer sleeve allows the wheels to be pressed on to P48 track gauge.

Now the fun begins...... Aluminium and brass are generally not compatible due to galvanic corrosion, however in my defence - the locomotive will be in a dry environment; the aluminium has sat around long enough to form a passive oxide layer and is held to the tube with Loctite retaining compound; the oil lubricant is not electrolytic, the axles will not be electrically live and finally....... no marine environment.

I did think of buying more brass tube then thought naaah, I'll leave the aluminium tube on the axle and see what happens as an experiment . So I have three brass axles in brass bearings and one aluminium axle in brass bearings - convention? what convention

. So I have three brass axles in brass bearings and one aluminium axle in brass bearings - convention? what convention  .

.

The next step was to check the trucks..... so I folded one up to check against a spare 40'' P48 wheelset.

A bit of an oh moment and now had to think about narrowing, yes folks that's narrowing the trucks. So as Napoleon and Snowball said while trotting around the rail yards... S7 wide frames P48 narrow frames, S7 wide frames P48 narrow frames, S7 wide frames P48 narrow frames......

moment and now had to think about narrowing, yes folks that's narrowing the trucks. So as Napoleon and Snowball said while trotting around the rail yards... S7 wide frames P48 narrow frames, S7 wide frames P48 narrow frames, S7 wide frames P48 narrow frames......

Again, using materials to hand I tack soldered a piece of 3mm brass angle to the inside of the truck using some brass bar as a spacer.

Snapped off the truck side frame.....

...cleaned it up and re-soldered this to the truck top and brass angle. This was repeated for the other side whilst maintaining the axle centres with 1/8'' aluminium tube.

And hey presto! The new truck with a P48 wheelset to check clearances.

After repeating this for the second truck I now have a pair of P48 compatible trucks and axles.

Obviously the ride height has been altered by a fraction but, if necessary, this can be compensated for during the remainder of the build.

It is designed to use Slaters lowmac wheels - but not for me though as this will be built to P48 track standards.

So having robbed these insulated 33'' wheels from some Northwest Short Line freight car wheelsets I set about making axles for P48 gauge.

Not bothering to follow convention to use steel, and not having a lathe to turn any, I used what I had in stock i.e. brass tube. I proceeded to make up the axles up from sleeved brass tube to fit standard 1/8'' top had bearing and accept the insulated wheels. Four axles were made and during the process I ran out of 1/8'' brass tube so one axle has an aluminium tube - gosh shock horror

. The outer sleeve allows the wheels to be pressed on to P48 track gauge.

. The outer sleeve allows the wheels to be pressed on to P48 track gauge.

Now the fun begins...... Aluminium and brass are generally not compatible due to galvanic corrosion, however in my defence - the locomotive will be in a dry environment; the aluminium has sat around long enough to form a passive oxide layer and is held to the tube with Loctite retaining compound; the oil lubricant is not electrolytic, the axles will not be electrically live and finally....... no marine environment.

I did think of buying more brass tube then thought naaah, I'll leave the aluminium tube on the axle and see what happens as an experiment

. So I have three brass axles in brass bearings and one aluminium axle in brass bearings - convention? what convention

. So I have three brass axles in brass bearings and one aluminium axle in brass bearings - convention? what convention  .

.The next step was to check the trucks..... so I folded one up to check against a spare 40'' P48 wheelset.

A bit of an oh

moment and now had to think about narrowing, yes folks that's narrowing the trucks. So as Napoleon and Snowball said while trotting around the rail yards... S7 wide frames P48 narrow frames, S7 wide frames P48 narrow frames, S7 wide frames P48 narrow frames......

moment and now had to think about narrowing, yes folks that's narrowing the trucks. So as Napoleon and Snowball said while trotting around the rail yards... S7 wide frames P48 narrow frames, S7 wide frames P48 narrow frames, S7 wide frames P48 narrow frames...... Again, using materials to hand I tack soldered a piece of 3mm brass angle to the inside of the truck using some brass bar as a spacer.

Snapped off the truck side frame.....

...cleaned it up and re-soldered this to the truck top and brass angle. This was repeated for the other side whilst maintaining the axle centres with 1/8'' aluminium tube.

And hey presto! The new truck with a P48 wheelset to check clearances.

After repeating this for the second truck I now have a pair of P48 compatible trucks and axles.

Obviously the ride height has been altered by a fraction but, if necessary, this can be compensated for during the remainder of the build.

Steph Dale

Western Thunderer

Dave,

Are you going to be driving the trucks as-designed? Looks like acetal chain drive, I guess? The only reason I'm asking is that the motor mounting will need an awful lot of stiffening up if you're to keep the loco quiet, if you're using that configuration.

Steph

Are you going to be driving the trucks as-designed? Looks like acetal chain drive, I guess? The only reason I'm asking is that the motor mounting will need an awful lot of stiffening up if you're to keep the loco quiet, if you're using that configuration.

Steph

JasonD

Western Thunderer

Nice use of tube Dave. If someone with 3d skills is reading this and is bored watching telly, how about a roller-bearing cap on a shaft to stick in the tube for freight car axles? Also fairly topic-unrelated - Mike Calvert you conversed with at Telford has plenty of P48 frt car wheelsets (NWSL I think) and for readers south of Yorkshire, etc, Winchester Meet is this Saturday

GE 70T

Yorkshire Dave

Western Thunderer

Well......  - this kit very nearly ended up in outer space to join Voyager beyond the heliosphere.........

- this kit very nearly ended up in outer space to join Voyager beyond the heliosphere.........

I started today knocking up the sill/chassis for the switcher and all was going well - apart from not being the mickootricki school of soldering.

So far so good. The next step was to make up the skeleton to form the hood/body which, again, was relatively simple. This is after I used the end piece in the hood.

The idea is to solder the centre beam to the centre of the hood piece and use it as a bending template to form a three sided box. Aah, seems straight forward I thought.... Ha! no....

Before bending the sheet to form the hood the louvre etches were made up and soldered in place.

As I was bending the hood the sides naturally wanted to bend at the half etch at the top of the doors - one bend seemed to go okay but the other was an absolute nightmare . So much so that the half etch at the top of the doors (blue box below) on one side split

. So much so that the half etch at the top of the doors (blue box below) on one side split

. As I kept trying to form the bend the air went from light blue through azure to ultramarine and was slowly diminishing my confidence with brass kits.

. As I kept trying to form the bend the air went from light blue through azure to ultramarine and was slowly diminishing my confidence with brass kits.

At this stage I may as well have taken the cash out of the bank, chucked a match at it and watch it melt. On the other hand tenners contain beef tallow so may have burnt brightly .

.

I kept on going and finally made up the bend with the assistance of a hammer for a bit of panel beating. The split mentioned above was repaired and now of course the end result is that the corners have more dents and bumps than a French car in a scrapyard. Anyway here is the hood thus far (on a 20 year old lump of wood).

And the inner end.

The hood corners have since been filed and coarse wet and dry sanded to try and reduce the dents but it won't be until the first coat of primer that I'll be able to see the damage . If it isn't too bad I'll incorporate them into the weathering.

. If it isn't too bad I'll incorporate them into the weathering.

- this kit very nearly ended up in outer space to join Voyager beyond the heliosphere.........

- this kit very nearly ended up in outer space to join Voyager beyond the heliosphere.........I started today knocking up the sill/chassis for the switcher and all was going well - apart from not being the mickootricki school of soldering.

So far so good. The next step was to make up the skeleton to form the hood/body which, again, was relatively simple. This is after I used the end piece in the hood.

The idea is to solder the centre beam to the centre of the hood piece and use it as a bending template to form a three sided box. Aah, seems straight forward I thought.... Ha! no....

Before bending the sheet to form the hood the louvre etches were made up and soldered in place.

As I was bending the hood the sides naturally wanted to bend at the half etch at the top of the doors - one bend seemed to go okay but the other was an absolute nightmare

. So much so that the half etch at the top of the doors (blue box below) on one side split

. So much so that the half etch at the top of the doors (blue box below) on one side split

. As I kept trying to form the bend the air went from light blue through azure to ultramarine and was slowly diminishing my confidence with brass kits.

. As I kept trying to form the bend the air went from light blue through azure to ultramarine and was slowly diminishing my confidence with brass kits.At this stage I may as well have taken the cash out of the bank, chucked a match at it and watch it melt. On the other hand tenners contain beef tallow so may have burnt brightly

.

.

I kept on going and finally made up the bend with the assistance of a hammer for a bit of panel beating. The split mentioned above was repaired and now of course the end result is that the corners have more dents and bumps than a French car in a scrapyard. Anyway here is the hood thus far (on a 20 year old lump of wood).

And the inner end.

The hood corners have since been filed and coarse wet and dry sanded to try and reduce the dents but it won't be until the first coat of primer that I'll be able to see the damage

. If it isn't too bad I'll incorporate them into the weathering.

. If it isn't too bad I'll incorporate them into the weathering.oldravendale

Western Thunderer

mickootriki

!

!

I reckon the lumps and bumps should be retained. Then when you are told how unreal it looks you can show them a photo of the real thing......

Brian

!

!I reckon the lumps and bumps should be retained. Then when you are told how unreal it looks you can show them a photo of the real thing......

Brian

Steph Dale

Western Thunderer

That's a fantastic recovery; hopefully it'll work well enough when you've got it under primer.

Steph

Steph

mickoo

Western Thunderer

Dave,

Nice recovery, likewise I think the dents and dings should be retained, with your weather artistry and the original models industrial heritage then it's to be expected and won't look out of place.

For the future and something I've done in the past with etch lines close to bend points, is to solder a backing piece on the inside and as close to where the bend for the bonnet top commences, it helps stop the material trying to bend at the half etch detail area.

MD

Nice recovery, likewise I think the dents and dings should be retained, with your weather artistry and the original models industrial heritage then it's to be expected and won't look out of place.

For the future and something I've done in the past with etch lines close to bend points, is to solder a backing piece on the inside and as close to where the bend for the bonnet top commences, it helps stop the material trying to bend at the half etch detail area.

MD

Jordan

Mid-Western Thunderer

Now he tells you........For the future and something I've done in the past with etch lines close to bend points, is to solder a backing piece on the inside and as close to where the bend for the bonnet top commences, it helps stop the material trying to bend at the half etch detail area.

MD

Yorkshire Dave

Western Thunderer

For the future and something I've done in the past with etch lines close to bend points, is to solder a backing piece on the inside and as close to where the bend for the bonnet top commences, it helps stop the material trying to bend at the half etch detail area.

Thanks for the tip for next time. We all live and learn.

GE 70T

Yorkshire Dave

Western Thunderer

Things have gone better today....

Added some 2mm angle on the chassis over which the hood sits. This serves two purposes; one - to keep the base of the hood straight; and two - to assist location on the chassis. The fuel tank was also assembled.

Then I started messing with the messing (groan, groan deutsche - messing = brass) cab. The doors have been cut out as I intend modelling them open and both front and rear replacement cab doors are provided on the etch.

deutsche - messing = brass) cab. The doors have been cut out as I intend modelling them open and both front and rear replacement cab doors are provided on the etch.

The Doh! moment . The cab ends are formed of a laminate and it was only after soldering them together I realised I could of used the inner laminate as the template for the glazing........ oh well. The cab end laminates also provide a neat way to to install the roof - especially as the corners are rounded.

Doh! moment . The cab ends are formed of a laminate and it was only after soldering them together I realised I could of used the inner laminate as the template for the glazing........ oh well. The cab end laminates also provide a neat way to to install the roof - especially as the corners are rounded.

And this is how the ensemble looks thus far....

This was the side which was repaired following the earlier disaster

Added some 2mm angle on the chassis over which the hood sits. This serves two purposes; one - to keep the base of the hood straight; and two - to assist location on the chassis. The fuel tank was also assembled.

Then I started messing with the messing (groan, groan

deutsche - messing = brass) cab. The doors have been cut out as I intend modelling them open and both front and rear replacement cab doors are provided on the etch.

deutsche - messing = brass) cab. The doors have been cut out as I intend modelling them open and both front and rear replacement cab doors are provided on the etch.

The

Doh! moment . The cab ends are formed of a laminate and it was only after soldering them together I realised I could of used the inner laminate as the template for the glazing........ oh well. The cab end laminates also provide a neat way to to install the roof - especially as the corners are rounded.

Doh! moment . The cab ends are formed of a laminate and it was only after soldering them together I realised I could of used the inner laminate as the template for the glazing........ oh well. The cab end laminates also provide a neat way to to install the roof - especially as the corners are rounded.

And this is how the ensemble looks thus far....

This was the side which was repaired following the earlier disaster

Yorkshire Dave

Western Thunderer

Yesterday was spent making up the smaller details such as laminating the cab doors (as they have detail both inside and out), cab steps and sill steps.

Adding: rainstrips to the cab doors, and cabinet doors; window armrests; and the roof - after taking a brass rubbing of the windows from the inside to provide glazing templates.

And earlier this week I carried out some more work on the hood corners. A bit more panel beating - this time from the inside to take some of the kinks out of the corners. All I did was: rest the hood upside down at 45 degrees, place short length of 2mm of steel rod into the corner and walloped this (well gently anyway) with a hammer and drift. I repeated this process along both sides of the hood. The end result is the tightening and straightening of the hood corners. This was then rubbed down with wet and dry emery cloth, brush painted with etch primer (white patches on the hood) to fill the minor abrasions and rubbed down again.

Almost forgot - made up and fitted the cab roof.

Adding: rainstrips to the cab doors, and cabinet doors; window armrests; and the roof - after taking a brass rubbing of the windows from the inside to provide glazing templates.

And earlier this week I carried out some more work on the hood corners. A bit more panel beating - this time from the inside to take some of the kinks out of the corners. All I did was: rest the hood upside down at 45 degrees, place short length of 2mm of steel rod into the corner and walloped this (well gently anyway) with a hammer and drift. I repeated this process along both sides of the hood. The end result is the tightening and straightening of the hood corners. This was then rubbed down with wet and dry emery cloth, brush painted with etch primer (white patches on the hood) to fill the minor abrasions and rubbed down again.

Almost forgot - made up and fitted the cab roof.

GE 70T

Yorkshire Dave

Western Thunderer

Yes, it's truck time........

..... for the 70 tonner.

Having narrowed the truck frame chassis earlier in the build now it came time to narrow the truck mounts as these carry the cast whitemetal sideframes.

Again it was a question of snapping the side mounts off the stretcher and re-soldering them inboard by the width of the cast whitemetal frame

Before (left) and after (right).

This time temporarily mounted on the truck chassis. Again before....

And after.

..... for the 70 tonner.

Having narrowed the truck frame chassis earlier in the build now it came time to narrow the truck mounts as these carry the cast whitemetal sideframes.

Again it was a question of snapping the side mounts off the stretcher and re-soldering them inboard by the width of the cast whitemetal frame

Before (left) and after (right).

This time temporarily mounted on the truck chassis. Again before....

And after.

GE 70T

Yorkshire Dave

Western Thunderer

Troublesome - well not now as I've done some more work on them and as usual with the benefit of hindsight - such as using screws when I narrowed the trucks and the photo is the final one of this sequence. If I thought it about the construction initially - rather than winging it as usual - I would have built the trucks differently.

I had originally intended to use an off the shelf 4mm drive from the Bachmann Al5 as it has the correct wheelbase but after checking it out it is too much of a faff to fit. So it's back to square one for the drive -bicycle delrin chain.... I've never assembled one before so it's a learning curve.

Anyway to continue....

Firstly the sideframes have been attached. They could do with a bit more depth around the springs - something which I may attend to later.

Then I added some 3mm angle brackets, drilled and tapped for M1.4 machine screws, inside the frames.

To support the stretcher which will carry the chain tensioner - made removable for access.

Brake gear added and the area supporting the motor 'beefed up' above and below with scrap nickel silver etch. I've also added M1.0 screws to provide additional fixing into the brass angle for the top and sideframes which prevents the whole ensemble collapsing into modern sculpture when applying heat from a soldering iron .

.

However, the additional fixings are all rather academic since the trucks are complete apart from the motor etc. On the other hand it has provided some valuable experience - Don't buy any more brass locomotive kits! .

.

It'll be unheeded as there will be another one on it's way . So I'll know what to do now in order to narrow the trucks for P48 if the kit is designed for OW5.......

. So I'll know what to do now in order to narrow the trucks for P48 if the kit is designed for OW5.......

I had originally intended to use an off the shelf 4mm drive from the Bachmann Al5 as it has the correct wheelbase but after checking it out it is too much of a faff to fit. So it's back to square one for the drive -

Anyway to continue....

Firstly the sideframes have been attached. They could do with a bit more depth around the springs - something which I may attend to later.

Then I added some 3mm angle brackets, drilled and tapped for M1.4 machine screws, inside the frames.

To support the stretcher which will carry the chain tensioner - made removable for access.

Brake gear added and the area supporting the motor 'beefed up' above and below with scrap nickel silver etch. I've also added M1.0 screws to provide additional fixing into the brass angle for the top and sideframes which prevents the whole ensemble collapsing into modern sculpture when applying heat from a soldering iron

.

.

However, the additional fixings are all rather academic since the trucks are complete apart from the motor etc. On the other hand it has provided some valuable experience - Don't buy any more brass locomotive kits!

.

.It'll be unheeded as there will be another one on it's way

. So I'll know what to do now in order to narrow the trucks for P48 if the kit is designed for OW5.......

. So I'll know what to do now in order to narrow the trucks for P48 if the kit is designed for OW5.......Yorkshire Dave

Western Thunderer

Spent several daylight hours at the workbench today and not much to show for it other than...

Fitting the rain strips (from kit) to the GE70T roof and making up some sun shades from 1.0 mm brass channel and scrap nickel silver.

Then faffing around making and painting some figures. These are made up from an Eduard 1:48 USAF ground personnel which suffices for railroad loco maintenance crew. You have to assemble the limbs, torso and head and the detail is not as good as Tamiya figures. These are unfinished and will receive further washes once the paint has dried hard. A rather cruel close up.

And this is what they're staring at.....

Fitting the rain strips (from kit) to the GE70T roof and making up some sun shades from 1.0 mm brass channel and scrap nickel silver.

Then faffing around making and painting some figures. These are made up from an Eduard 1:48 USAF ground personnel which suffices for railroad loco maintenance crew. You have to assemble the limbs, torso and head and the detail is not as good as Tamiya figures. These are unfinished and will receive further washes once the paint has dried hard. A rather cruel close up.

And this is what they're staring at.....

GE 70T

Yorkshire Dave

Western Thunderer

With the festivities over some time was spent messing about with the trucks.

I've never used the Delrin chain drives before so the first stage was to try and quieten the noisy (to me anyway) gears. In order polish them I used silicon carbide lapping compound as used by the automotive industry and stone/rock polishers.

The trucks were supported in free space (well sort of) and the silicon carbide paste dripped onto the gears. They were then left to run for 60 minutes (30 in either direction). Care was taken to ensure the lapping paste did not enter the motor and once complete the motors were removed from the trucks. The worm gears and trucks were then washed in a degreaser , rinsed and left to dry.

The motors were reinstalled and the Delrin chain added. As is the case - take a link out of the chain it's too tight and leave the link in it's too loose. I opted for the latter and made up some some 'slipper blocks' / tensioners from scrap nickel silver and brass channel. These mount with M1.4 machine screws into tapped brass angle soldered to the inside of the truck frames.

The assembled trucks and the home brewed power pick up and motor connectors. A separate wiring loom will be made to connect to the decoder.

This just shows how far the motors reach above the sill. The steps were also added.

As I had not built the kit as per the instructions and in order to secure the cab to the chassis I tapped (for M1.4 machine screws) four lengths of brass tube and soldered these into the corners of the cab. They sit below the cab floor which has been modified to to accommodate these.

And the 70T so far.

I've never used the Delrin chain drives before so the first stage was to try and quieten the noisy (to me anyway) gears. In order polish them I used silicon carbide lapping compound as used by the automotive industry and stone/rock polishers.

The trucks were supported in free space (well sort of) and the silicon carbide paste dripped onto the gears. They were then left to run for 60 minutes (30 in either direction). Care was taken to ensure the lapping paste did not enter the motor and once complete the motors were removed from the trucks. The worm gears and trucks were then washed in a degreaser , rinsed and left to dry.

The motors were reinstalled and the Delrin chain added. As is the case - take a link out of the chain it's too tight and leave the link in it's too loose. I opted for the latter and made up some some 'slipper blocks' / tensioners from scrap nickel silver and brass channel. These mount with M1.4 machine screws into tapped brass angle soldered to the inside of the truck frames.

The assembled trucks and the home brewed power pick up and motor connectors. A separate wiring loom will be made to connect to the decoder.

This just shows how far the motors reach above the sill. The steps were also added.

As I had not built the kit as per the instructions and in order to secure the cab to the chassis I tapped (for M1.4 machine screws) four lengths of brass tube and soldered these into the corners of the cab. They sit below the cab floor which has been modified to to accommodate these.

And the 70T so far.