GE 70T

Yorkshire Dave

Western Thunderer

Valhalla

Well...... I spent ages trying to get these to run smoothly but not to my satisfaction .

.

So after ripping out the consumable items: truck frames, motors, gears etc both of the internal truck frames were given a viking funeral with the aid of a blowtorch .

.

Ashes

Not the disaster of the series down under - instead the truck chassis remains of after cleaning up...

Phoenix

Not even Arizona as it been snowing again this morning...... to continue I decided to remake the truck chassis using parts rummaged from the 'that'll come in useful one day' crate. Aye, there's nowt like a good old rummage... .

.

These were parts left over from my 4mm and HO modelling days way back when. Alan Gibson hornblocks, one flexible coupling and a pair of Exactoscale 2:1 reduction gearboxes (one shown below of which the bottom gear is mounted on a sleeve to accommodate a 2mm shaft

I also purchased four of these...

As the Alan Gibson hornblocks and Slaters gearboxes utilise 1/8'' axles so I cut four new axles from steel rod (two have already been used). Protocraft 36'' Grabowski insulated wheels were used this time as they fit onto a 1/8'' shaft.

After cutting the frames to take the hornguides the first job was to install these and add the 3mm brass angle to the top for mounting to the top plate.

The Protocraft wheels have a pronounced boss on the inside the top of the truck chassis was narrowed to 23mm to allow for this and insulated spacing washers.

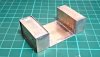

After Much Faffing in the Marsh and building the Slaters gearboxes, mounting the hornblocks, insulating washers and wheels to the axles - this is the end result.

Not elegant from the underside but it does work.... I've lost some of the mounting holes but no worries. - my prime objective here is to get the entire drive train working first and consider the rest later .

.

And testing..... Eventually the motor will sit in the fuel tank and the propshafts will be shortened to fit and horizontal.

Just another one to make now..... and source a short flexible coupling followed by fine tuning.

It might not be the most efficient drive and as it's for a switcher kicking a few boxcars - am I bovvered ..... nah.

..... nah.

Well...... I spent ages trying to get these to run smoothly but not to my satisfaction

.

.

So after ripping out the consumable items: truck frames, motors, gears etc both of the internal truck frames were given a viking funeral with the aid of a blowtorch

.

.Ashes

Not the disaster of the series down under - instead the truck chassis remains of after cleaning up...

Phoenix

Not even Arizona as it been snowing again this morning...... to continue I decided to remake the truck chassis using parts rummaged from the 'that'll come in useful one day' crate. Aye, there's nowt like a good old rummage...

.

.These were parts left over from my 4mm and HO modelling days way back when. Alan Gibson hornblocks, one flexible coupling and a pair of Exactoscale 2:1 reduction gearboxes (one shown below of which the bottom gear is mounted on a sleeve to accommodate a 2mm shaft

I also purchased four of these...

As the Alan Gibson hornblocks and Slaters gearboxes utilise 1/8'' axles so I cut four new axles from steel rod (two have already been used). Protocraft 36'' Grabowski insulated wheels were used this time as they fit onto a 1/8'' shaft.

After cutting the frames to take the hornguides the first job was to install these and add the 3mm brass angle to the top for mounting to the top plate.

The Protocraft wheels have a pronounced boss on the inside the top of the truck chassis was narrowed to 23mm to allow for this and insulated spacing washers.

After Much Faffing in the Marsh and building the Slaters gearboxes, mounting the hornblocks, insulating washers and wheels to the axles - this is the end result.

Not elegant from the underside but it does work.... I've lost some of the mounting holes but no worries. - my prime objective here is to get the entire drive train working first and consider the rest later

.

.

And testing..... Eventually the motor will sit in the fuel tank and the propshafts will be shortened to fit and horizontal.

Just another one to make now..... and source a short flexible coupling followed by fine tuning.

It might not be the most efficient drive and as it's for a switcher kicking a few boxcars - am I bovvered

..... nah.

..... nah.

.

. The 3/16" axle will be a benefit for one of the applications, may be both.

The 3/16" axle will be a benefit for one of the applications, may be both.

they're in hornblock(?) guides. They're like what I could do with on my Atlas SD40 so it could tackle my kind of track.

they're in hornblock(?) guides. They're like what I could do with on my Atlas SD40 so it could tackle my kind of track.