adrian

Flying Squad

Finally decided to break cover with my second scratchbuild project. A few hints have been dropped over the year and I'll be oscillating between this and the Sentinel build as the mood takes me.

So project No.2 is a Precursor Tank - I'm still not sure why. I just fancied building something pre-grouping and being a member of the L&Y Soc. and the L&NWR Soc. I was flicking between the 2 companies for the next build. Having seen some LNWR loco's and stock at last years Scale7 North meet I settled on the Precursor Tank, the final decision was due to the excellent digital archive of the L&NWR Soc. from where full GA drawings where available to members which is a boon for scratch building.

So yes I'm aware there are kits available but as I always seem to end up modifying them in someway I decided to go back to my roots and do a pure scratch build project. I have also decided to do a full blow by blow account of the build to show that scratch building is not difficult and having dealt with a few ropey kits I still maintain that any competent kit builder would have no problem scratchbuilding.

So this time in the correct wheel arrangement, a set of Slaters wheels were purchased and turned to Scale7 standards.

I decided to start with the front bogie as I always prefer to get a rolling chassis before starting on any bodywork. A couple of strips of nickel-silver are soldered together and marked with engineering blue (a.k.a. a sharpie pen!) so that the marking out can be easily seen. The bogie will be fully sprung and compensated, as close to prototype as possible - hence marking out the hornguides as rectangular rather than a circular hole for a brass bush. Nothing more complicated is required than a scriber, a square, odd-leg calipers, dividers and a 6" rule. When looking at the GA drawings it is quite often easy to spot where the original draughtsman set the origin for his dividers as there is a dot on the drawings, this allows me to work out the correct radii for many of the curved sections.

A little time with the piercing saw and fettling with needle files gives me 2 bogie sideframes.

The axles will be fitted with miniature ball races held in a little 3D printed carrier. So brass angle is soldered to the side frames. A length of 5/16" bar is used to space the angle when soldering to ensure the horn guides are parallel and correct separation. The compensation beams and frame spacer are also cut out from n/s sheet.

On the prototype the springing is done by means of a leaf spring from a central angle bolster, I'm not convinced leaf springs (or coil springs for that matter) scale very well so I usually look to using wire springs if I can ( hence continuous springy beams etc.) So the plan here is to have the central bolster to provide compensation and then hide the wire springing inside the compensation beam with a dummy leaf spring to hide it.

The wire spring feeds through a central brass block acting as the fulcrum point - the end of the wire then rests on the top of the axle hornblock. The slot in the frame spacer is curved, again matching the GA drawing and I intended to fit a side control spring - hence the slot rather than a simple bogie pivot.

So the bogie side frames and frame spacer soldered together.

There are half a dozen other L&NWR loco's I'd like to build at some point and there are several common components used across the different classes so the experience and thought in building this should make it easier for any subsequent builds, which would be easier if there was a set of good quality tender kits available.

So project No.2 is a Precursor Tank - I'm still not sure why. I just fancied building something pre-grouping and being a member of the L&Y Soc. and the L&NWR Soc. I was flicking between the 2 companies for the next build. Having seen some LNWR loco's and stock at last years Scale7 North meet I settled on the Precursor Tank, the final decision was due to the excellent digital archive of the L&NWR Soc. from where full GA drawings where available to members which is a boon for scratch building.

So yes I'm aware there are kits available but as I always seem to end up modifying them in someway I decided to go back to my roots and do a pure scratch build project. I have also decided to do a full blow by blow account of the build to show that scratch building is not difficult and having dealt with a few ropey kits I still maintain that any competent kit builder would have no problem scratchbuilding.

So this time in the correct wheel arrangement, a set of Slaters wheels were purchased and turned to Scale7 standards.

I decided to start with the front bogie as I always prefer to get a rolling chassis before starting on any bodywork. A couple of strips of nickel-silver are soldered together and marked with engineering blue (a.k.a. a sharpie pen!) so that the marking out can be easily seen. The bogie will be fully sprung and compensated, as close to prototype as possible - hence marking out the hornguides as rectangular rather than a circular hole for a brass bush. Nothing more complicated is required than a scriber, a square, odd-leg calipers, dividers and a 6" rule. When looking at the GA drawings it is quite often easy to spot where the original draughtsman set the origin for his dividers as there is a dot on the drawings, this allows me to work out the correct radii for many of the curved sections.

A little time with the piercing saw and fettling with needle files gives me 2 bogie sideframes.

The axles will be fitted with miniature ball races held in a little 3D printed carrier. So brass angle is soldered to the side frames. A length of 5/16" bar is used to space the angle when soldering to ensure the horn guides are parallel and correct separation. The compensation beams and frame spacer are also cut out from n/s sheet.

On the prototype the springing is done by means of a leaf spring from a central angle bolster, I'm not convinced leaf springs (or coil springs for that matter) scale very well so I usually look to using wire springs if I can ( hence continuous springy beams etc.) So the plan here is to have the central bolster to provide compensation and then hide the wire springing inside the compensation beam with a dummy leaf spring to hide it.

The wire spring feeds through a central brass block acting as the fulcrum point - the end of the wire then rests on the top of the axle hornblock. The slot in the frame spacer is curved, again matching the GA drawing and I intended to fit a side control spring - hence the slot rather than a simple bogie pivot.

So the bogie side frames and frame spacer soldered together.

There are half a dozen other L&NWR loco's I'd like to build at some point and there are several common components used across the different classes so the experience and thought in building this should make it easier for any subsequent builds, which would be easier if there was a set of good quality tender kits available.

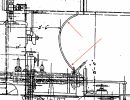

) as indicated although it is not dimensioned it is not difficult to work out the radius centre point from the marks on the drawing.

) as indicated although it is not dimensioned it is not difficult to work out the radius centre point from the marks on the drawing.