25. Brake Gear

The instructions omit any explanation of how to assemble the brake gear, so I present one here. I assembled the right side first, and found it thoroughly fraught and difficult. Taking some photographs of the procedure next time seemed calming so here is the build of the left side.

The parts involved are:

- the cast brake shoes and some wire to represent the pivots

- 12 actuating lever

- 13 pull rod

- 11 actuating rod

- 10 brake crank

written out here in sequence of initial placement

With a rigid rear axle (hard tail?) the brake blocks go close to the wheels without fear of shorting.

For the front brakes (where the wheels have suspension), I tried and failed with smears of Araldite and settled on gluing strips of thin card onto the brake blocks. I touched these with sanding sealer before trimming to final size. They are nearly impossible to see, so no photo.

I had managed to lose the second actuating lever so I made a new one. Once again I am thankful to

@Martin Shaw who let me have his stash of old frets. Thanks Martin, it has made me all kinds of detail parts.

The actuating lever has received one pivot pin, and some Blu Tack stops it falling out.

The actuating rod has received both of its pins, and is again placed loosely. The actuating rod has to go on now, because it ends up underneath the next part. "Do not remove the Blu Tack yet". Truly. If you do, start again . . .

The pull rod has received both of its pivot pins, and is soldered into place at both ends. Doing this sets the angle of the actuating lever, so this can be fixed into place too.

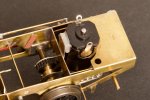

The crank (above the hair pin) is trimmed, and added to the assembly. The crank is resting on the heavy transverse rod (*). This sets up the final angle of the actuating rod, so the crank and actuating rod are soldered together. There is a loose washer waiting behind the crank.

The actuating rod is soldered onto the actuating lever. A second washer has been placed onto the heavy transverse rod.

The two loose washers are brought together and soldered up to create a boss for the crank.

(*) Please excuse me if I am using the wrong terminology. I am taking it from the instructions where I can, but I had to make this up.

And there it is. I have finally realised, the kit instructions are almost certainly the work of two people. Firstly (I suspect), someone who designed and built the kit, who prepared the illustrations; and then someone who had never built the kit and added a narrative. This would explain why the illustrations are genuinely useful; and the narrative is virtually free of useful information. I accept, the instructions are of their time, as is the kit; I expect will try something more recent next time. Or, as a kindly member of NEEGOG suggested yesterday, scratchbuild. At least I would know where all the parts were meant to go.

) it’s a push rod.