You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tom Mallard’s Workbench L&B in 7mm scale, CR 828 in 7mm, GWR Saints in 4mm

- Thread starter Tom Mallard

- Start date

Tom Mallard

Western Thunderer

Looking magnificent, Tom. Also, I just love the thought process that resulted in the front valve chests being part of the body, rather than the chassis, to allow separation.

Dave.

I sort of liked the idea too, Dave, but it results in a lot of very careful fitting between the cylinder front and the back of the valve chest, and the top edge of the footplate with the cylinder wrapper, plus it’s all gently inclined at 1 in 40! So a practical necessity, and necessary evil.

Tom

Tom Mallard

Western Thunderer

Significant progress toward completion of the O1 this time, as the chassis and body have had their remaining details added. The chassis needs thoroughly checking for smoothness under power, and as yet there is quite a bit of drag from the motion and the pickups in particular. I may remove one pair of these.

Although pretty cruel in close up, the cab is reasonably well detailed and will gain its gauges once painting is complete. The backhead is removable via undoing a pair of screws which pass through the footplate and cab floor. On recent models I have decided to make the coupling pipes between engine and tender as part of the pipework of the engine, leaving them unattached to the tender. so long as there is something bridging the gap in the gloom beneath the fall plate I think this is OK. Certainly compared to the headache of making something flexible connected at both ends.

Really looking forward to priming the model and getting the top coat on.

I planned to leave the model to 'rest' for a few days so that any omissions might present themselves. I don't need to wait so long as they're showing themselves as I upload the images...

Enjoy your modelling.

Tom

Tom Mallard

Western Thunderer

Black engines are hard to photograph against a white background. Do not inadvertently read anything political or otherwise into that statement, as I have just done. It's good to be sensitive about what one writes.

I sprayed 2 part etching primer before a coating of satin black cellulose (the gloss had dried up). Ideally I would have prefered to mix gloss and satin about 50/50. After the brilliant Fox transfers and works plates (some spare Martin Finney ones) had been applied, I varnished over with a 50/50 mix of Railmatch satin and Phoenix gloss varnish. I expect I should have stuck with one brand but they both said enamel on the jar/tin.

Weathering combines airbrushing and manual brushing using a sable brush. I'm still new to weathering as I don't often have much to practise on, but it is great fun. The engine is supposed to look fairly clean, and is likely a little cleaner than it would have been in the late 1930's. Somehow it looks more dirty in real life than in the photos.

The crew is again from my own 4mm scale range.

3458 (as it is now shown to be) came out well enough in the end, but some emergency tweeking was required to eliminate the combination lever bobbing up and down when the engine was in motion. I retrofitted a carefully made tube to the cylinders so that the valve spindle could slide but not rock up and down. The tube goes right throught the cylinder assembly and valve guide as I'd luckily left a pilot hole in the front face which lines up with the spindle.

Also the front platform is now screwed down to avoid inadvertently damaging this area when handling the loco.

It glides along nicely, and it would be lovely to see it pulling a proper coal train someday.

The next period of work is to include some 7mm scale Lynton and Barnstaple Manning Wardles, something I have been looking forward to for a while now.

Best regards

Tom

Scale7JB

Western Thunderer

It's very rare that I look at WT on a computer, and seeing as now on a big screen its even better. Magnificent job.

Cant wait for the L&B locos! one of my favourites. I was tempted to draw up some etches for these in 7mm myself, but I'm too lazy to go searching for decent drawings and I have a couple of other projects I want to draw up after the current D16, so a little way off.

JB.

Cant wait for the L&B locos! one of my favourites. I was tempted to draw up some etches for these in 7mm myself, but I'm too lazy to go searching for decent drawings and I have a couple of other projects I want to draw up after the current D16, so a little way off.

JB.

Tom Mallard

Western Thunderer

Such pretty colours.

Stage 1 for any of my projects is to source original drawing information, together with suitable photos. For these famous Manning Wardle engines I got lucky (dug deep) and had access to a set of drawings for LEW. There are numerous detail differences between LEW and the origianl trio of EXE, TAW and YEO, which entailed fastidious examination of earlier drawing material and photographs.

The most obvious differences were made to the original three as their cabs were modified in the earlier years of the railway. This change was the most difficult to resolve as there is no drawing record for this.

To this end I must identify my primary resource: I've been supported in my work most generously by Stephen Phillips, L&B expert and author of The Lynton & Barnstaple Railway Measured and Drawn, which in my view is a sublime and flawless work.

Mostly it's all there in the CAD drawing now, ready for me to develop the models from.

Best regards

Tom

Last edited:

Tim Watson

Western Thunderer

Looking awfully familiar. Currently turning the cylinders and slide bars for my Yeo.

Tim

Tim

Tom Mallard

Western Thunderer

Once again, no real model exists yet.

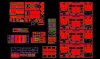

I've generally completed the extensive detailed work developing the CAD model into information for each component part of the model that is intended to be made from sheet metal. These have been grouped together by one of seven different metal thicknesses appropriate to the part and will be etched to shape.

Overall this is the single most time consuming part of developing my models, as most parts are related to at least one other and so success depends on these fitting together properly. I have worked hard to ensure accuracy at this stage, covering small variations between engines and getting all the rivets correctly positioned in and around the cab - shown by the 4 right hand panels one each for YEO, EXE and TAW, plus a 'blank'.

Once the metal has been delivered the super exciting part of putting together a physical model can begin!

Next, I will likely move to pattern making and planning how best to assemble some nice wheelsets.

Work is in hand for the commission of name and number plates from Diane Carney which I'm hoping will come out well.

Best regards

Tom

Tom Mallard

Western Thunderer

Fantastic. I'd imagine these etches won't be available to the common user?

JB.

Unfortunately they fall into my usual category of 'not for sale' unless included in a model of the engine.

Tom

Tom Mallard

Western Thunderer

All the etches are back from PPD, who as usual have done a good job. They are very shiney. Fingers crossed that it all fits, and I've not omitted anything important to the design.

In a shocking turn of events, I am investigating the use of 3D printed patterns. I have taken some convincing that the quality of this process can match that of handmade patterns, but I believe the process might now be satisfactory for certain types of part which are either cast on the prototype and/or do not rely on a very smooth overall surface finish.

I've posted a couple of my digital patterns to make a comparison with the patterns I make manually or by analogue processes. I quite enjoy modelling parts in CAD, and compared with the 2D AutoCAD parts, these are nicer to work on as they don't rely on on fitting their neighbouring parts in quite the same way. Just as with hand made patterns, I can only expect them to be as good as the information and effort put into them before they are cast. The wheel pattern will be adapted so that it can be machined to fit a tyre - I don't intend to cast the tyre.

There are a number of pitfalls I can see with digital patterns, based mainly on my nature. Literally all detail can be included whether practical or sensible or neither. The smallest thing can be modelled with ease without regard to how well it will reproduce. It's very easy to loose sight of a detail that adds time to making the model but nothing at all to the finished model.

For my digital pattern making I grasped the function of Fusion360 and find it's quite impressive for a package that can be so easily downloaded. I wouldn't say it's anything like as robust as SolidWorks, or as powerful, but that is definitely not what it is aimed at.

Once I am satisfied with the CAD models I intend to have them printed in a castable wax, omitting the mouldmaking part usually associated with the lost wax process. The aim is to reduce loss of resolution by using one fewer process, and to maintain dimensional stability. However, my caster pointed out that castings of the wax masters, if given the right shrinkage allowance can also be used as patterns once cleaned and polished if I am in particular need of a very good surface finish. We will see.

If some of these don't work out I can still use each 3D model to generate a dimensioned drawing and do it all by hand...

So, I'm jumping in with both feet and hoping for the best!

Best regards

Tom

Last edited:

Tom Mallard

Western Thunderer

Faster than a speeding glacier.

Lots of varied tasks are distilling toward something which will look like the prototype. Also tasks of revisions, pattern making and detailing have been examined.

The frames and buffer beams have contributed a lot of fretting as I established that not all of the detail could be embossed to the level of relief I wanted. In the end, much of what is a bolt head on the prototype is represented by a wire pin - correct in this case as these don't have a hexagonal head. I'll have to keep an eye out for those which are either a nut or hexagonal bolt head...

The tank design has come out well, and presents a trying bend on the outside face. A small jig facilitates forming this.

All the templates for profiling the valve gear have been made (sorry Adrian this will be in nickel silver) and I'm looking forward to this.

Compared with a tender engine, the Manning Wardles and their large enclosed cabs present some construction challenges which interfere with making rapid progress as I feel a lot of detailing will have to done in advance of the front and rear being permanently attached.

My digital patterns have been printed as waxes, and sent to my caster. Fingers crossed.

Best regards

Tom

Tom Mallard

Western Thunderer

The bogie stretcher humps have all been made up - two profile machined ends, a sheet top surface and then a slightly troublesome machine operation for the angled faces on my Sixis 1101 mill to get them right.

The removeable floor section in the cab area is hopefully going to facilitate finishing the interior along with probably a removable roof.

Two different rivet patterns for the front footplates and varying sizes and reliefs should keep the rivet counters happy.

The motion and valvegear templates are ready for action, reproduced at 5:1. This is larger than normal, but narrow gauge engines have smaller parts and using the larger scale should be better? Yes, I know, actual hand made parts.

This will be a lot of work building up the different relief levels, but to me is very much worth it.

Best regards

Tom

Dave Holt

Western Thunderer

All looking very nice and neat, Tom, as we've come to expect. The outside Joy valve gear is probably not a joy to replicate. The curved guides look good.

I have dreamed of fitting working Joy gear to an ex-L&Y 0-6-0 but these guides are a real problem without any machining facilities.

Dave.

I have dreamed of fitting working Joy gear to an ex-L&Y 0-6-0 but these guides are a real problem without any machining facilities.

Dave.

Tom Mallard

Western Thunderer

Dave, I think the curved guides for your 0-6-0 would be a problem generally if this is 4mm scale?All looking very nice and neat, Tom, as we've come to expect. The outside Joy valve gear is probably not a joy to replicate. The curved guides look good.

I have dreamed of fitting working Joy gear to an ex-L&Y 0-6-0 but these guides are a real problem without any machining facilities.

Dave.

Tom Mallard

Western Thunderer

YEO's cab under way. Some of the detailing has already been included and this conveniently stiffens up the 8thou nickel silver cab sheeting.

Something which is not clear on any drawings are the retrofitted bunker mounted seats for the driver and fireman. I will have to deduce how this looks as there are only views of part of this in the photos I have. Possibly it is just a piece of plate formed into an angle, riveted or bolted to the front of the bunker with a wooden seat surface.

At some point, duck boards will be added to the cab to build the floor level up to match the hump in the middle. It must have been a trip hazard at the start of these engine's lives.

Best regards

Tom

Tom Mallard

Western Thunderer

Progress on some Manning Wardle smokebox/boiler/firebox assemblies. Normally these would be aligned with a screw along the centre line to hold things in place. I wanted the assembly to be unimpeded by this type of construction so ring type formers are used with pins arranged around this area as shown on the face down smokebox of YEO.

The saddle for the smokebox is fabricated and will have to be very carefully set so as to maintain a boiler parallel with the frames and tanks. After testing the tanks against the cabsides and smokebox, I think it will be safer and simpler to add the tanks after the boiler assembly has been attached to the cab and footplate assembly.

For the brass firebox front and rear I invested in a radius milling cutter to generate a consistent radius on these parts. I machined them on my pantograph milling machine (quite a cold day or so stuck in the garage!) as a secondary operation during manufacture, and they came out alright. It would certainly have been a substantial headache to profile the internal radius on the backhead area. The firebox fittings will likely be attached to a separate plate representing the firebox front.

Best regards

Tom

Attachments

Tom Mallard

Western Thunderer

There are some bits and bobs to fill the footplate of these engines now, all machined, turned and fabricated as required. Not entirely sure the 0.5mm hex heads on the brake standard are worth it but at least we know they're there. The cab interior is going to be on view on the models, yet remains almost invisible in nearly every photograph of the prototype due to glare from the glazing and the nature of outdoor photography.

The castings are made directly from 3D printed waxes and are largely as hoped for, though I was expected a less matte finish. I am particularly pleased with the motion brackets which are nice and flat, and the coupling pockets.

Best regards

Tom

Last edited: