You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

V2 4 wheel parcel van1/32 and G3

- Thread starter michael mott

- Start date

michael mott

Western Thunderer

Nick that is great, thank you. That will work well.

Michael

Michael

michael mott

Western Thunderer

Thanks for the additional information going to square makes a lot of sense being a forging.

Michael

Michael

michael mott

Western Thunderer

michael mott

Western Thunderer

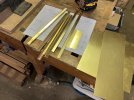

Next step was to get the 3 1/2 dimension accurate, the cut on the tablesaw was cut about.030” oversized because it was apparent from the first piece that there was a little variation end to end. I set up the mill to do this with bars of mild steel stock for stops and clamps.

I used a climb cut so that the brass was pushed towards the 3/8” steel backstop.

Next the angles have been roughly marked for cutting and fitting before the holes for the various other frame joining angles and W irons etc are done.

Now the fun part begins.

Michael

I used a climb cut so that the brass was pushed towards the 3/8” steel backstop.

Next the angles have been roughly marked for cutting and fitting before the holes for the various other frame joining angles and W irons etc are done.

Now the fun part begins.

Michael

michael mott

Western Thunderer

First major scewup I set the height gauge to measure the 10.486 length of the sole bars

Marked both and cut them when laid next to my ruler they were too short?

A few naughty words echoed around the room!

First glance 10.486…… what was happening

Ah a classic mistake!

So I had to make two new bars it was a good job I had left the mill set up so after bending new bars I milled the new ones. So much work for .1”

Time for tea.

Michael

Marked both and cut them when laid next to my ruler they were too short?

A few naughty words echoed around the room!

First glance 10.486…… what was happening

Ah a classic mistake!

So I had to make two new bars it was a good job I had left the mill set up so after bending new bars I milled the new ones. So much work for .1”

Time for tea.

Michael

Jon Nazareth

Western Thunderer

Er, what was the classic mistake, Michael?First major scewup I set the height gauge to measure the 10.486 length of the sole bars

View attachment 208973

Marked both and cut them when laid next to my ruler they were too short?

View attachment 208977

A few naughty words echoed around the room!

View attachment 208975

First glance 10.486…… what was happening

View attachment 208976

Ah a classic mistake!

So I had to make two new bars it was a good job I had left the mill set up so after bending new bars I milled the new ones. So much work for .1”

View attachment 208978

Time for tea.

Michael

Jon

michael mott

Western Thunderer

hi Jon

Misreading the digital information on the instrument.

Michael

Misreading the digital information on the instrument.

Michael

michael mott

Western Thunderer

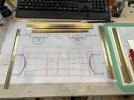

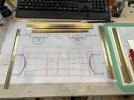

I spent most of the day yesterday studying all the photos and drawings that have been procured. The net result is a bit of a change in the layout of the steel for the frame. The 4wheel Dean coach restoration picture of the frame, and the pictures that Simon posted and one drawing I found on the web helped rework the frame. The frame is only 21 foot 5inches long and from the info In Russell’s booklet to the rework. Withou a definitive drawing of this particular coach built in 1876 I realize there might be some differences or errors. The new layout seems reasonably close and will support the other elements that form part of the Dean clasp brakes.

The first basic design.

The current layout.

And the updated drawing.

By placing the 2 center angles to create a channel it allows for the bar that connects the coupling hooks. The one part that is still unclear is how a bar that connects the hook at each end works with the traverse leaf springs at each end. The only way I can see is if there is a spring device at the center of the bar.

Michael

The first basic design.

The current layout.

And the updated drawing.

By placing the 2 center angles to create a channel it allows for the bar that connects the coupling hooks. The one part that is still unclear is how a bar that connects the hook at each end works with the traverse leaf springs at each end. The only way I can see is if there is a spring device at the center of the bar.

Michael

Lyndhurstman

Western Thunderer

The RCH drawing here shows the central spring https://www.cs.rhul.ac.uk/~adrian/steam/RCHWagons/images/rch1001.PDFI spent most of the day yesterday studying all the photos and drawings that have been procured. The net result is a bit of a change in the layout of the steel for the frame. The 4wheel Dean coach restoration picture of the frame, and the pictures that Simon posted and one drawing I found on the web helped rework the frame. The frame is only 21 foot 5inches long and from the info In Russell’s booklet to the rework. Withou a definitive drawing of this particular coach built in 1876 I realize there might be some differences or errors. The new layout seems reasonably close and will support the other elements that form part of the Dean clasp brakes.

The first basic design.

View attachment 209128

The current layout.

View attachment 209130

And the updated drawing.

View attachment 209131

By placing the 2 center angles to create a channel it allows for the bar that connects the coupling hooks. The one part that is still unclear is how a bar that connects the hook at each end works with the traverse leaf springs at each end. The only way I can see is if there is a spring device at the center of the bar.

Michael

ChrisBr

Western Thunderer

Michael,

I notice Pete's drawing does not show through connection between the drawbars and whilst I don't know about the V2, the 4 wheel underframe drawing I have from 1891 does not have any connection between draw gear/buffing springs. Certainly 4 plank wagons did not have that connection prior to 1895.

You may be able to make life easy for your self and leave it out....

Chris

I notice Pete's drawing does not show through connection between the drawbars and whilst I don't know about the V2, the 4 wheel underframe drawing I have from 1891 does not have any connection between draw gear/buffing springs. Certainly 4 plank wagons did not have that connection prior to 1895.

You may be able to make life easy for your self and leave it out....

Chris

michael mott

Western Thunderer

Another discovery that really matters was that my hand held dial caliper that I had been using to measure the 3 1/2 x 9 angle was not zeroed it had a .058” negative reading at the zero position. Which meant that the dimensions were off. I only discovered it when I was carefully lining up one of the angled pieces and noticed that the 3 1/2 “ dimension was too wide when placed over the drawing. Perhaps I should go back to cardboard!

So I also took the opportunity to also tighten up the corner bend now that the pieces are mostly shorter than 4 inches actual I placed each piece one at a time in my old mill vice and with a hammer and a chunk of steel flattened the bend to create a nice tight corner. Then started to put them back on the mill to reduce to the correct .155” dimension. Once those are done I can set up for the 9 “ dimension which is.498”.

It is a good job I am not doing this commercially or I would be seriously considering a different job like ditch digging.

Michael

So I also took the opportunity to also tighten up the corner bend now that the pieces are mostly shorter than 4 inches actual I placed each piece one at a time in my old mill vice and with a hammer and a chunk of steel flattened the bend to create a nice tight corner. Then started to put them back on the mill to reduce to the correct .155” dimension. Once those are done I can set up for the 9 “ dimension which is.498”.

It is a good job I am not doing this commercially or I would be seriously considering a different job like ditch digging.

Michael

michael mott

Western Thunderer

michael mott

Western Thunderer

A test to confirm if riveting will work and it does

These rivets are 1/32 diameter by 1/4 “ long so I had to snip them to the proper length after inserting the angle thickness is only .018” x 2 the next task is to sort out the domed head for the visible surface on the sole bars. The test was accomplished with a pair of parallel pliers. And the copper rivets are soft enough that it squashes the rivet easily. I am going to make a small hemispherical head that I can glue on one face of the pliers jaws out of silver steel and harden it.

Michael

These rivets are 1/32 diameter by 1/4 “ long so I had to snip them to the proper length after inserting the angle thickness is only .018” x 2 the next task is to sort out the domed head for the visible surface on the sole bars. The test was accomplished with a pair of parallel pliers. And the copper rivets are soft enough that it squashes the rivet easily. I am going to make a small hemispherical head that I can glue on one face of the pliers jaws out of silver steel and harden it.

Michael

michael mott

Western Thunderer

I think that making a dome head will be ok a further test with the method described in the previous post, the key will be having the correct amount sticking out to dome.

Now to clean up the tooling and have a go at a couple of the challenging joints as tests. The last picture is showing a rivet made from a small 1/4" copper nail. Which is great because I have hundred of them.

Michael

Now to clean up the tooling and have a go at a couple of the challenging joints as tests. The last picture is showing a rivet made from a small 1/4" copper nail. Which is great because I have hundred of them.

Michael