Pencarrow

Western Thunderer

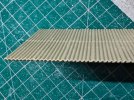

I think it would be quite simply butted up to the door or window frame without any ceremony. A shed like this would not be a sophisticated as a 'tin tabernacle' or a station building designed around people.

This one is at Yeovil Junction may give assist A corrugated iron structure seen at Yeovil Junction Railway Station Stock Photo - Alamy

Looks like a very similar structure. Asbestos roof tin sides. Thanks Dave.