simond

Western Thunderer

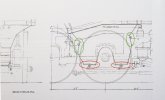

Following a post many years back by David LO Smith, I adopted, adapted, and I think, improved the design he suggested. He said it wasn’t his idea anyway, but I think of it in that way.

there were photos, but RMW lost them, and I haven’t built another one since, and sold the loco so can't take any more!

These are my third iteration of David’s sketch. I think they’re the easiest version to make.

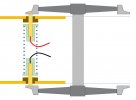

There are simple flanged Tufnol bushes glued in the frames, these are drilled 2mm. They can be any convenient size, but want to be a couple of mm long to support and guide the plungers.

The plungers are 2mm brass rod, centre drilled at one end to form a solder pocket, once the wire is soldered in, they are pressed into a simple plastic top hat bush which insulates the plunger from the spring. The wire simply passes between the coils of the spring. The plungers have to be long enough to touch the wheel back, with a bit of clearance between the top hat bush and the Tufnol bush.

The springs I use are spares from Premier Components couplings.

Where the axle has side play, the whole assembly moves to and fro with the axle, thus maintaining contact, and not “putting the brakes on”. The plungers can be removed from the frames without removing the wheels, which is a further benefit.

I used Tufnol for the frame bushes because I had some, and it takes epoxy well. The plunger bushes were turned up from some knitting needle

there were photos, but RMW lost them, and I haven’t built another one since, and sold the loco so can't take any more!

These are my third iteration of David’s sketch. I think they’re the easiest version to make.

There are simple flanged Tufnol bushes glued in the frames, these are drilled 2mm. They can be any convenient size, but want to be a couple of mm long to support and guide the plungers.

The plungers are 2mm brass rod, centre drilled at one end to form a solder pocket, once the wire is soldered in, they are pressed into a simple plastic top hat bush which insulates the plunger from the spring. The wire simply passes between the coils of the spring. The plungers have to be long enough to touch the wheel back, with a bit of clearance between the top hat bush and the Tufnol bush.

The springs I use are spares from Premier Components couplings.

Where the axle has side play, the whole assembly moves to and fro with the axle, thus maintaining contact, and not “putting the brakes on”. The plungers can be removed from the frames without removing the wheels, which is a further benefit.

I used Tufnol for the frame bushes because I had some, and it takes epoxy well. The plunger bushes were turned up from some knitting needle

Last edited:

I'm guessing on the firebox/grate, but I've not found any pictures either in my books or online. Can anyone help please?

I'm guessing on the firebox/grate, but I've not found any pictures either in my books or online. Can anyone help please?