You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Richard Spoors

Western Thunderer

P A D

Western Thunderer

Steven,

Thanks for the kind words, but I assure you there is far more solder on the model than I would have liked. Just like the Mickoos, Dikitrikis and others on here, I try to use the minimum amount of solder required to do the job, but it doesn't always work out like that. Then it's lots of elbow grease with scrapers and the glass fibre scratchy brush. Of course, whenever possible I solder on the inside and then I can be as profligate with the solder as I like.

I see Simon, Warren (who has the model for painting) and Richard have kindly answered your question and there's nothing further I can add.

It's a wonderfull kit who's design concept by Martin Finney has been taken to the next level by Mick Davies at F7 with their W1 kit. Enjoy the rest of your build.

Cheers,

Peter

Thanks for the kind words, but I assure you there is far more solder on the model than I would have liked. Just like the Mickoos, Dikitrikis and others on here, I try to use the minimum amount of solder required to do the job, but it doesn't always work out like that. Then it's lots of elbow grease with scrapers and the glass fibre scratchy brush. Of course, whenever possible I solder on the inside and then I can be as profligate with the solder as I like.

I see Simon, Warren (who has the model for painting) and Richard have kindly answered your question and there's nothing further I can add.

It's a wonderfull kit who's design concept by Martin Finney has been taken to the next level by Mick Davies at F7 with their W1 kit. Enjoy the rest of your build.

Cheers,

Peter

Dog Star

Western Thunderer

The photos of the ejector pipe fitted to the engine suggest that the pipe is straight between smokebox and cab... which implies that the brackets for the pipe are of different lengths - is that correct?Some further work on decorating the body before moving back to the chassis. First I soldered the fixing brackets to the ejector pipe. Here it is after removal for cleaning up.

View attachment 95150

thank you, Graham

mickoo

Western Thunderer

No, pipe is straight, clips are all same length....well, except the firebox one which is shorter by a measure not easily measured and if measured of no measure worth concerning oneself.The photos of the ejector pipe fitted to the engine suggest that the pipe is straight between smokebox and cab... which implies that the brackets for the pipe are of different lengths - is that correct?

thank you, Graham

garethashenden

Western Thunderer

This thread is fantastic! Great workmanship and it will be invaluable to me when I get back to my P4 version.

Robin A

Member

An excellent thread which I shall refer to when I commence my 7mm Finney kit.

Bye the Bye I have already donated the Finney kit full valances to a 'Little Jim' A4 that I am working on at present as I found the rivet detail somewhat indifferent on the originals. They are a perfect fit with no adjustment.

Rob

Bye the Bye I have already donated the Finney kit full valances to a 'Little Jim' A4 that I am working on at present as I found the rivet detail somewhat indifferent on the originals. They are a perfect fit with no adjustment.

Rob

P A D

Western Thunderer

First off all, thanks for all the kind words on my Martin Finney A3 thread after my recent post.

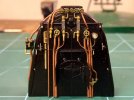

Following on from that, I've finally got around to reassembling the Finney 7 A4, which was expertly painted and lined by Warren Haywood some time ago. Here's the loco chassis after painting the wheels and refitting, along with the valve gear and motor.

This image shows the valve gear set in full reverse but it can of course be moved to full forward as designed.

A close up of the working lubricator linkages and with the pick ups added.

And with the bogie and trailing axle added.

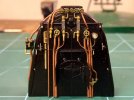

Here are some views of the completed tender. Apologies for the dust on the model but I'm working in my garage now which is not the cleanest of environments.

And the backplate and cab dials which are located on backing plates on the underside of the cab roof. Some touching up around the dials and on the backplate is still to be done.

Cheers,

Peter

Following on from that, I've finally got around to reassembling the Finney 7 A4, which was expertly painted and lined by Warren Haywood some time ago. Here's the loco chassis after painting the wheels and refitting, along with the valve gear and motor.

This image shows the valve gear set in full reverse but it can of course be moved to full forward as designed.

A close up of the working lubricator linkages and with the pick ups added.

And with the bogie and trailing axle added.

Here are some views of the completed tender. Apologies for the dust on the model but I'm working in my garage now which is not the cleanest of environments.

And the backplate and cab dials which are located on backing plates on the underside of the cab roof. Some touching up around the dials and on the backplate is still to be done.

Cheers,

Peter

Last edited:

P A D

Western Thunderer

Thank you David.

Completed at last. I took these images on the garden wall in the afternoon as the lighting is better than on my bench in the garage.

It needs a few spoonfuls of coal in the tender.

Note the bent steam pipes on this side. I straightened them before taking further images below.

The valve and thin pipe above the nameplate is the steam feed for the whistle. On the real thing there is a lever on the valve that runs back to the cab behind the large pipe. This connects to the handle in the cab for operating the whistle. When I built Golden Fleece from the long defunct Acme kit some years ago, I added the lever and cable. However, it's barely noticeable on the prototype, let alone a 7mm model so I left it off this one.

This is the front end of the model build from the Acme Kit. You can see the cable behind the large pipe from this angle but mostly it's invisible. That's my excuse for being a lazy git any way!

The Acme kit can be built into a nice model of the A4 but you have to work much harder to achieve a good result than you do with the F7 kit. It was a more economical alternative to the Finney and DJH kits, and it included parts to build pretty much all variants of the A4, although not the streamlined non corridor tender. The valve gear could be made workable but the design was more complex and less builder friendly than the F7 kit so I opted for having it fixed in forward gear.

Building the boiler is more akin to ship modelling as the boiler cladding is built up around an inner skeleton/framework. Building this makes you realise just how much time and effort is saved by the F7 resin boiler!

But I digress. Here are views of the tender front and cab interior. I've just realised I've overlooked painting the boards on the tender floor! That's not an oversight by Warren as he was only required to do the main painting and lining. I painted the wheels and cab interior.

Next up I will be continuing my build of the Stanier 3P 2-6-2t from the etchings supplied by Mike Edge. I need to add the motor and pick ups and then dismantle and paint. Once that's done I need to paint my two class 4 2-6-4 tank locos, one from MOK and the other from David Andrews, so I'll be resurrecting those threads as well.

Cheers,

Peter

Completed at last. I took these images on the garden wall in the afternoon as the lighting is better than on my bench in the garage.

It needs a few spoonfuls of coal in the tender.

Note the bent steam pipes on this side. I straightened them before taking further images below.

The valve and thin pipe above the nameplate is the steam feed for the whistle. On the real thing there is a lever on the valve that runs back to the cab behind the large pipe. This connects to the handle in the cab for operating the whistle. When I built Golden Fleece from the long defunct Acme kit some years ago, I added the lever and cable. However, it's barely noticeable on the prototype, let alone a 7mm model so I left it off this one.

This is the front end of the model build from the Acme Kit. You can see the cable behind the large pipe from this angle but mostly it's invisible. That's my excuse for being a lazy git any way!

The Acme kit can be built into a nice model of the A4 but you have to work much harder to achieve a good result than you do with the F7 kit. It was a more economical alternative to the Finney and DJH kits, and it included parts to build pretty much all variants of the A4, although not the streamlined non corridor tender. The valve gear could be made workable but the design was more complex and less builder friendly than the F7 kit so I opted for having it fixed in forward gear.

Building the boiler is more akin to ship modelling as the boiler cladding is built up around an inner skeleton/framework. Building this makes you realise just how much time and effort is saved by the F7 resin boiler!

But I digress. Here are views of the tender front and cab interior. I've just realised I've overlooked painting the boards on the tender floor! That's not an oversight by Warren as he was only required to do the main painting and lining. I painted the wheels and cab interior.

Next up I will be continuing my build of the Stanier 3P 2-6-2t from the etchings supplied by Mike Edge. I need to add the motor and pick ups and then dismantle and paint. Once that's done I need to paint my two class 4 2-6-4 tank locos, one from MOK and the other from David Andrews, so I'll be resurrecting those threads as well.

Cheers,

Peter

Silverystreaks

Western Thunderer

P A D

Western Thunderer

Hi Bob,

It's Peter not Mick.

The chimney as supplied is correct for those engines fitted with double chimneys by the LNER. It doesn't take much effort to modify the shape to match the BR pattern, which I think you have done on your excellent model. However, as the bulk of the engines were fitted with the BR pattern, it would make more sense for F7 to supply a casting for that.

Cheers,

Peter

It's Peter not Mick.

The chimney as supplied is correct for those engines fitted with double chimneys by the LNER. It doesn't take much effort to modify the shape to match the BR pattern, which I think you have done on your excellent model. However, as the bulk of the engines were fitted with the BR pattern, it would make more sense for F7 to supply a casting for that.

Cheers,

Peter

Silverystreaks

Western Thunderer

My apologies Peter for getting your name wrong. Obviously, I've spent far too long following Mickoo's WT submissionsHi Bob,

It's Peter not Mick.

The chimney as supplied is correct for those engines fitted with double chimneys by the LNER. It doesn't take much effort to modify the shape to match the BR pattern, which I think you have done on your excellent model. However, as the bulk of the engines were fitted with the BR pattern, it would make more sense for F7 to supply a casting for that.

Cheers,

Peter

My A4 was completed some years ago and was my first Finney build followed by an A3, V2 and a Duchess. All of which were a pleasure to build.

Though quite a bit of lead was needed to pack the resin boilers. No requirement for any replacement castings

Regards

Bob