You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm Finney Battle of Britain

- Thread starter mickoo

- Start date

mickoo

Western Thunderer

Never said a word, nor have they in the past and I've never thought about the wastage in their tanks, but it is a valid point.Hi Mick,

Have PPD not mentioned about having so much metal to eat away? I thought they got a bit funny about large areas needing to be etched.

JB.

To be fair the etch is so delicate that adding fills in between the ribs to reduce wastage would be a complete nightmare to cut out without damaging the bit you want to keep, so much so that it'd almost be a non starter.

They seem more concerned about artwork below their tolerances, I don't think I've even had one piece that ever met there specifications, yet all etch perfectly fine even down to the smallest detail. I suppose they have to have 'safe' values to work to and I do have to let them know in writing that I accept all responsibility for under sized art work.

MD

Steph Dale

Western Thunderer

Mick,

One trick is not to tab in the wastage areas in the panels, they then drop clear and can be recovered from the scrap baskets in the bottom of the tank. Etching away will affect the chemistry in the tank, but if they're not bothered there's no reason for you to be!

Steph

One trick is not to tab in the wastage areas in the panels, they then drop clear and can be recovered from the scrap baskets in the bottom of the tank. Etching away will affect the chemistry in the tank, but if they're not bothered there's no reason for you to be!

Steph

Steph Dale

Western Thunderer

JB,

Other etching companies may not be so tolerant of the practice, but with PPD you should be okay.

Steph

Other etching companies may not be so tolerant of the practice, but with PPD you should be okay.

Steph

Eastsidepilot

Western Thunderer

mickoo

Western Thunderer

Cheers Col, makes my job easier when working out the overlays for the Slaters wheels

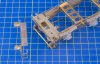

Moving onward, chassis now complete, well nearly, the white metal brake cylinders were damaged so require new brass pull rods and fittings so as soon as the required bits arrive in the post I'll fabricate some new ones and then fit it all into place and finally fit the hoses on the buffer beam.

The hand brake pull rod and linkages is a fiendish design my messers Bulleid and Co, especially as it is all tucked in behind the rear ladder, but with care it all fits in...just

One modification I did do, which helped with the hand brake linkage fabrication, was to make the rear buffer beam with attached steps as a removable component. It also means I can work on it on the bench whilst adding the detail and allows the self containing buffers to be fitted once it's all painted, otherwise you have to try and solder the retaining washer through all the hand brake linkage and steps, or solder before the buffer beam is fitted and then mask.

Two very handy brackets on the tender base nicely hold the tail end of the cast ladders so its a case of just sliding in and fixing with two 10BA bolts and I'll need to drill two clearance holes in the tender base to clear the screw heads.

It also allows it to be primed light grey then sprayed red with the steps brush painted in black later; it also allows the whole chassis to be primed black and not worry about masking the grey primer or red on the buffer beam.

Looking at the photos I've just realized I've missed of the small coal space slacking pipe, Bulleid tenders have a water spray system to keep dust levels down, that'll be this afternoons chore...sorry task

MD

Moving onward, chassis now complete, well nearly, the white metal brake cylinders were damaged so require new brass pull rods and fittings so as soon as the required bits arrive in the post I'll fabricate some new ones and then fit it all into place and finally fit the hoses on the buffer beam.

The hand brake pull rod and linkages is a fiendish design my messers Bulleid and Co, especially as it is all tucked in behind the rear ladder, but with care it all fits in...just

One modification I did do, which helped with the hand brake linkage fabrication, was to make the rear buffer beam with attached steps as a removable component. It also means I can work on it on the bench whilst adding the detail and allows the self containing buffers to be fitted once it's all painted, otherwise you have to try and solder the retaining washer through all the hand brake linkage and steps, or solder before the buffer beam is fitted and then mask.

Two very handy brackets on the tender base nicely hold the tail end of the cast ladders so its a case of just sliding in and fixing with two 10BA bolts and I'll need to drill two clearance holes in the tender base to clear the screw heads.

It also allows it to be primed light grey then sprayed red with the steps brush painted in black later; it also allows the whole chassis to be primed black and not worry about masking the grey primer or red on the buffer beam.

Looking at the photos I've just realized I've missed of the small coal space slacking pipe, Bulleid tenders have a water spray system to keep dust levels down, that'll be this afternoons chore...sorry task

MD

mickoo

Western Thunderer

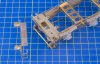

The cab interior frame work is in and to be blunt, I'm in two minds to progress it further, it adds but also it takes away whilst adding to the complexity and difficulty of the build. In an ideal world you wouldn't start here.

The frame work is currently in three pieces, necessary to get it inside a cab already built, no doubt about the cart being before the horse here! What is abundantly clear is that it's better off being fitted way back at the start when the cab sheet is flat, nothing I can do about that in this situation but that's the way forward and the artwork has been revamped to suit that method. Fitting it now also makes in near impossible to clean up the ugly solder, it's smooth and will take paint but for photography looks a dogs dinner.

It covers the rivet holes nicely so that's one plus but to cover the grooves for bending requires a false section of plate work to be added above the side windows, which is not prototypical. Thus, the choice is the inside of the cab looking like Ypes in 1916 or clean with an incorrectly added plate. I could extend the plate up to the next bracing in the roof so visually it'd look like the cab roof underside, but you'd loose half the depth of the ribs.

The only down side to adding it when the cab is flat is that you have to then bend it all with the rivets pressed out as these need doing first, you can't add it after the cab is bent as the inner piece grows due to the shorter radius so it ends up too low around the window areas, lesson truly learnt with even three smaller pieces.

Still the photos, still need to add a large baulk along the top of the side windows which will close that area there better.

I've a couple of spare cab sheets here so will try a MkII on these and see how easy it is to bend up and maybe one of the test etches will have full sheet work above the windows to see what the reduced rib height will look like, rubbish I expect .

.

If one were to start on a green field site then the external skin would be a half etch piece with the rivets already etched on the outside, to which an internal etch sheet with the ribs would be sweated on, no half etch holes or slots for bending to cover. There'd be no risk of damaging the etched rivets whilst bending to shape either.

MD

The frame work is currently in three pieces, necessary to get it inside a cab already built, no doubt about the cart being before the horse here! What is abundantly clear is that it's better off being fitted way back at the start when the cab sheet is flat, nothing I can do about that in this situation but that's the way forward and the artwork has been revamped to suit that method. Fitting it now also makes in near impossible to clean up the ugly solder, it's smooth and will take paint but for photography looks a dogs dinner.

It covers the rivet holes nicely so that's one plus but to cover the grooves for bending requires a false section of plate work to be added above the side windows, which is not prototypical. Thus, the choice is the inside of the cab looking like Ypes in 1916 or clean with an incorrectly added plate. I could extend the plate up to the next bracing in the roof so visually it'd look like the cab roof underside, but you'd loose half the depth of the ribs.

The only down side to adding it when the cab is flat is that you have to then bend it all with the rivets pressed out as these need doing first, you can't add it after the cab is bent as the inner piece grows due to the shorter radius so it ends up too low around the window areas, lesson truly learnt with even three smaller pieces.

Still the photos, still need to add a large baulk along the top of the side windows which will close that area there better.

I've a couple of spare cab sheets here so will try a MkII on these and see how easy it is to bend up and maybe one of the test etches will have full sheet work above the windows to see what the reduced rib height will look like, rubbish I expect

.

.If one were to start on a green field site then the external skin would be a half etch piece with the rivets already etched on the outside, to which an internal etch sheet with the ribs would be sweated on, no half etch holes or slots for bending to cover. There'd be no risk of damaging the etched rivets whilst bending to shape either.

MD

Last edited:

mickoo

Western Thunderer

Deflector extras now completed and off to the etchers ready for Reading.

Essentially all of the other deflectors not catered for in the kit and available individually (one set fits one loco). There is one other type which is an extended wrap around affair, much too complex for a flat etch without some complex forming dies.

The Devon Belle one is the standard deflector with the Devon Belle clip, then we have the three exchange locos, 34005 fitted with the Devon Belle clip, 34004 and 34006 without, both have sand box openings with sliding covers to pose open or closed as well as the extended fixing ladders. In addition both types are also available with the sand box opening sealed to suit later in their lives. Finally we have the extended type unique to Boscastle with the revised lower skirt as well (cut back and full variant's) as it was slightly longer along the top edge to meet the enlarged deflector.

MD

Essentially all of the other deflectors not catered for in the kit and available individually (one set fits one loco). There is one other type which is an extended wrap around affair, much too complex for a flat etch without some complex forming dies.

The Devon Belle one is the standard deflector with the Devon Belle clip, then we have the three exchange locos, 34005 fitted with the Devon Belle clip, 34004 and 34006 without, both have sand box openings with sliding covers to pose open or closed as well as the extended fixing ladders. In addition both types are also available with the sand box opening sealed to suit later in their lives. Finally we have the extended type unique to Boscastle with the revised lower skirt as well (cut back and full variant's) as it was slightly longer along the top edge to meet the enlarged deflector.

MD

Last edited:

Steph Dale

Western Thunderer

Mick,

Have you got the 'Early' and 'Late' the right way round on the Boscastle deflectors? Normally the cut back fairing in front of the cylinders was a later mod. Of course, I may have massively misunderstood what I'm looking at...!

Steph

Have you got the 'Early' and 'Late' the right way round on the Boscastle deflectors? Normally the cut back fairing in front of the cylinders was a later mod. Of course, I may have massively misunderstood what I'm looking at...!

Steph

mickoo

Western Thunderer

Meh!Mick,

Have you got the 'Early' and 'Late' the right way round on the Boscastle deflectors? Normally the cut back fairing in front of the cylinders was a later mod. Of course, I may have massively misunderstood what I'm looking at...!

Steph

Corrected

Also realized the longer deflectors will require a longer bending tool, so a little jiggery pokery in Autocad later, one tool supplied per set of long deflectors.

I'll flesh them out into a multiple sheet later.

MD

Pencarrow

Western Thunderer

Mick, just like me with my work you are your own worst critic. The extra cab interior fretwork looks absolutely superb fitted and IMO really adds to the overall look. Looks like a sod to fit and makes 'solder free' difficult but the former is character forming and the latter won't be an issue once painted. I certainly see no dogs dinner.

Really impressed with the choice of smoke detectors. Carry on!

Really impressed with the choice of smoke detectors. Carry on!

Last edited:

mickoo

Western Thunderer

....... but the former is character firming.......

They tell me this at work "this next project will be good character building" broken down to street level dialogue it equates to a world of pain, dirt, anger and wasted time

I don't want to form any more characters thank you

not at my age, I prefer to work smarter not harder

not at my age, I prefer to work smarter not harder

What follows are my own views and are not a criticism of the kit, build quality or design, it is a solo chariot I choose to ride.

Overall the overlay works very well and you're right, tricky to fit once the cab has been almost completed (own goal), it wasn't initially in the thought process, more a pie in the sky whim, but as with all itches at some point they need scratching so a test etch was made. I knew the bend slots were always going to be a headache as there is no prototypical plate work to cover it up as the ribs cover the rivet holes.

A cover was trialed and whilst covering the slots isn't prototypical, but then neither are the slots it tries to cover, which leaves you with two choices, unreal slots or an unreal cover plate, both wrong and whilst the cover plate looks marginally better falls under the mantra 'two wrongs do not make a right'.

So that's where it all sits right now, I've done a MkII overlay without cover plates and will run one test sheet off, just in case there's any interest but I suspect I'm out here on my own on this fixation

MD

john lewsey

Western Thunderer

That cab is stunning

Dog Star

Western Thunderer

Nope, wrong...... I've done a MkII overlay without cover plates and will run one test sheet off, just in case there's any interest but I suspect I'm out here on my own on this fixation...

Steph Dale

Western Thunderer

Driving wheel overlay, hopefully get the bogie and tender ones done tomorrow and all off with the insulated axle box tender chassis for a test etch by weeks end.

View attachment 60462

MD

Like it. Need a few of the 3'6" variety for some electric locos.

More seriously (!), it looks great and building out the front of the wheel will be good. I noted from Col's post that even the Harris wheels aren't quite right. The potential is definitely in the Slaters version.

Steph

mickoo

Western Thunderer

Steph, it's hard to get the shapes spot on as your relying on the underlying wheel casting to be correct as well, if that's out or the openings too small then your overlay has to follow or else you'll get a step between the two if the overlay is the correct shape / size and larger than the underlying casting.Like it. Need a few of the 3'6" variety for some electric locos.

More seriously (!), it looks great and building out the front of the wheel will be good. I noted from Col's post that even the Harris wheels aren't quite right. The potential is definitely in the Slaters version.

Steph

Electric wheels are easy enough, you'd have to use the Slaters 3'-7" as the donor and I'd assume the electric loco wheels would have the same hole arrangement as the Merchant Navy Delta truck wheel, of which the Slaters 3'-7" is designed for.

MD

Steph Dale

Western Thunderer

Mick,

Yeah, as far as I can tell all the 3'7" wheels whether for the MN truck, tenders, electric locos or the trio had the same wheel.

With the Radley models electric locos and their future release of 10201-3 I'm considering producing a suitable bogie, in which case having the overlays available is a great time saver.

Steph

Yeah, as far as I can tell all the 3'7" wheels whether for the MN truck, tenders, electric locos or the trio had the same wheel.

With the Radley models electric locos and their future release of 10201-3 I'm considering producing a suitable bogie, in which case having the overlays available is a great time saver.

Steph