mickoo

Western Thunderer

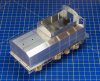

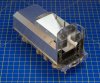

It also allows you to add the intermediate buffers and rubbing plates and allows soldering from the rear, especially the intermediate buffer spigots, once the draw bar plate is fitted, access to the rear of those spigots is near impossible; which means soldering from the front....and more cleaning up.Great idea Mick!Wish I’d thought of that, whilst doing my drawbars and buffer beams on my 4MT tender...

Regards

Dan

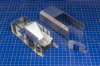

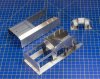

I also added the riveted strip along the top of outer frames before fitting them to the floor, instructions say the other way. Experience has shown me that soldering a thin half etched strip up and under there is a wide open door for Captain cock up and his merry crew to visit, and, near impossible to clean up effectively.

I did the same with the H15 bogie side frames, made the laminates up, dressed the edges all nice and smooth, then trimmed the twist tabs back to leave just enough of a tab to locate the side frame and then dabbed with solder. The same applies to the bearing plate/stretcher, there are six tabs that come up through inner frame to hold that laminate in place, if I had left them as twist tabs then I would of been dressing back on a visible surface and you always end up with some form of marking, that once painted, looks a witch.

My view of twist tabs is that they are handy, and very welcome in most cases, but not a mandatory usage.

off then spray Limelite....in my case......and after 15 seconds wash away with hot water; seems to do the trick here.

off then spray Limelite....in my case......and after 15 seconds wash away with hot water; seems to do the trick here. Another trick is to blot dry immediately, kitchen roll is best, leaves less fibres.....otherwise I find the water (we have hard water here) leaves a stain.

Another trick is to blot dry immediately, kitchen roll is best, leaves less fibres.....otherwise I find the water (we have hard water here) leaves a stain. .

.

.

.