Rob Pulham

Western Thunderer

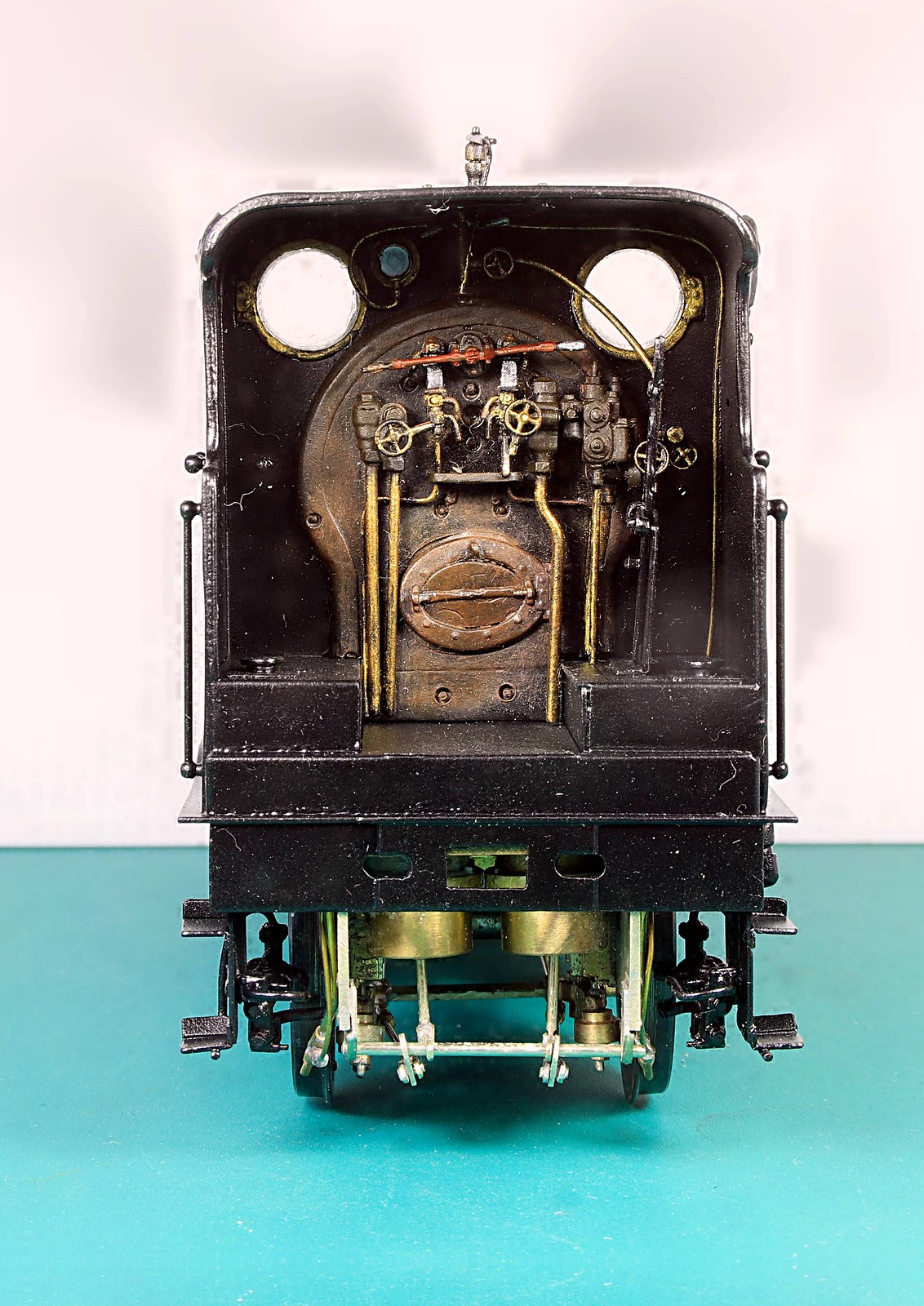

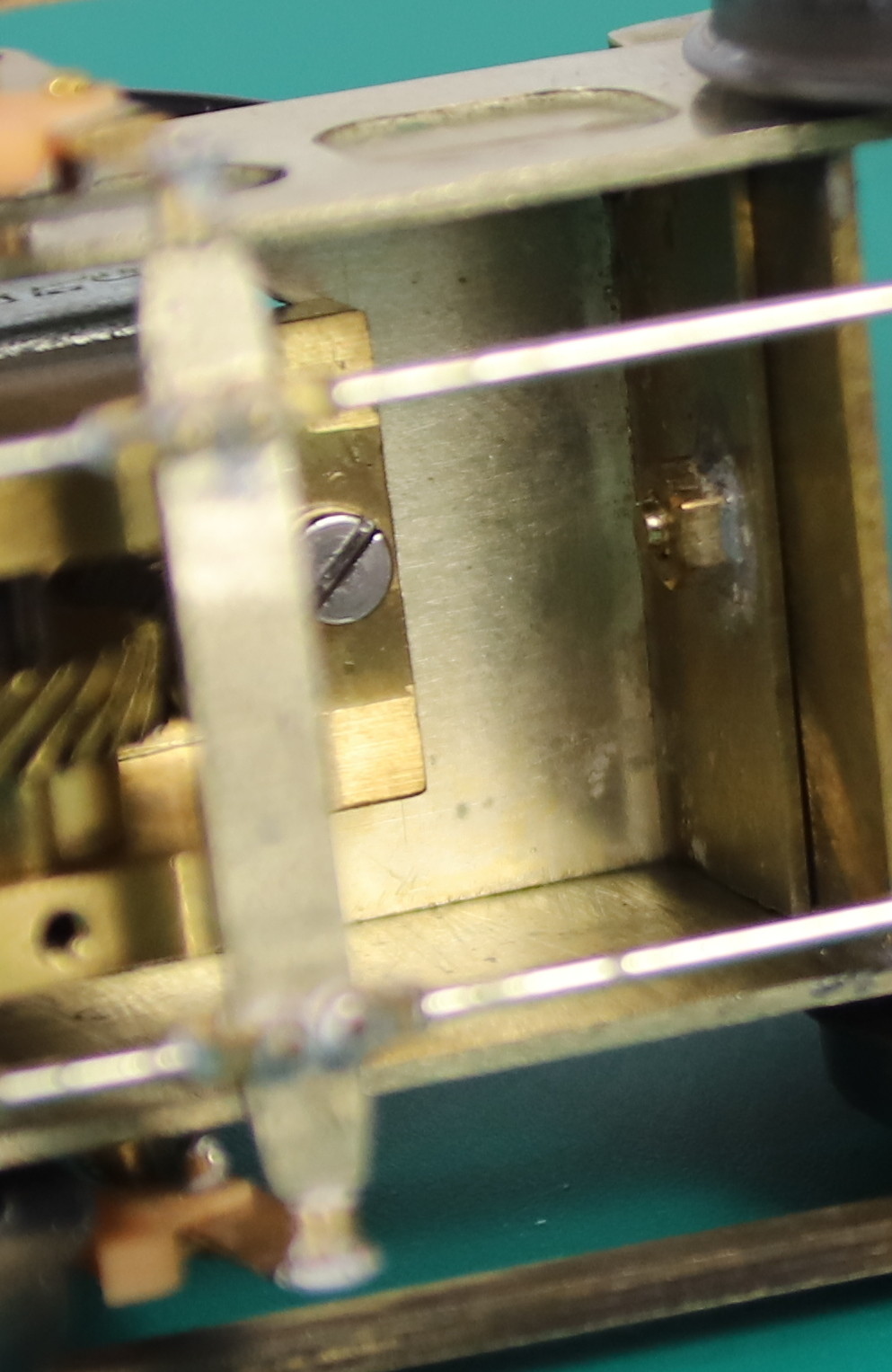

Still making slow but steady progress in between with the J6.

The tender is now coaled and ready for weathering. I plan to weather the loco and tender at the same time so that I get them looking the 'same'

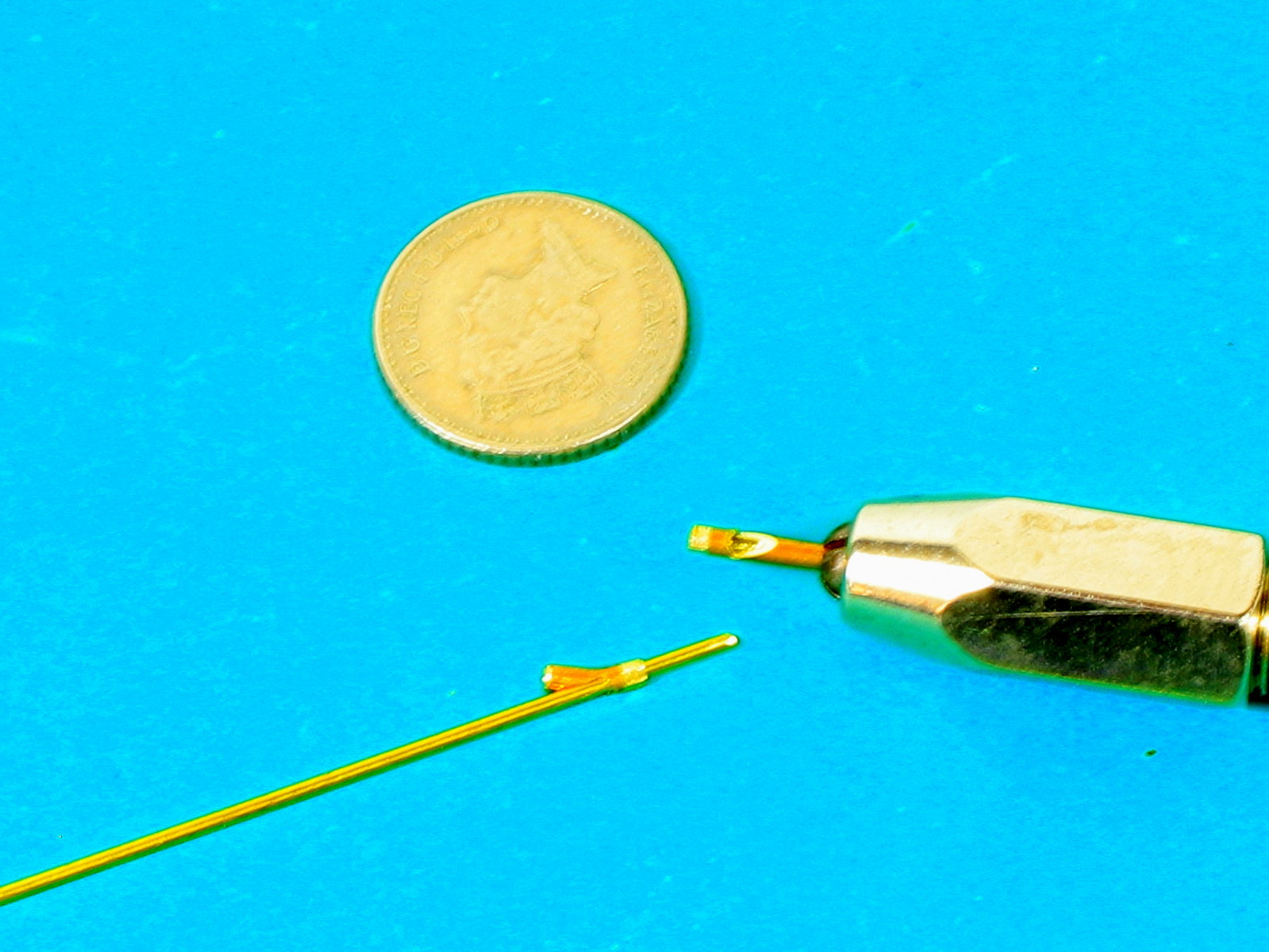

I almost forgot, I dropped the LG Miniatures fire irons in some dilute metal black which has given them a nice 'rusty' appearance.

The tender is now coaled and ready for weathering. I plan to weather the loco and tender at the same time so that I get them looking the 'same'

I almost forgot, I dropped the LG Miniatures fire irons in some dilute metal black which has given them a nice 'rusty' appearance.