Tim Watson

Western Thunderer

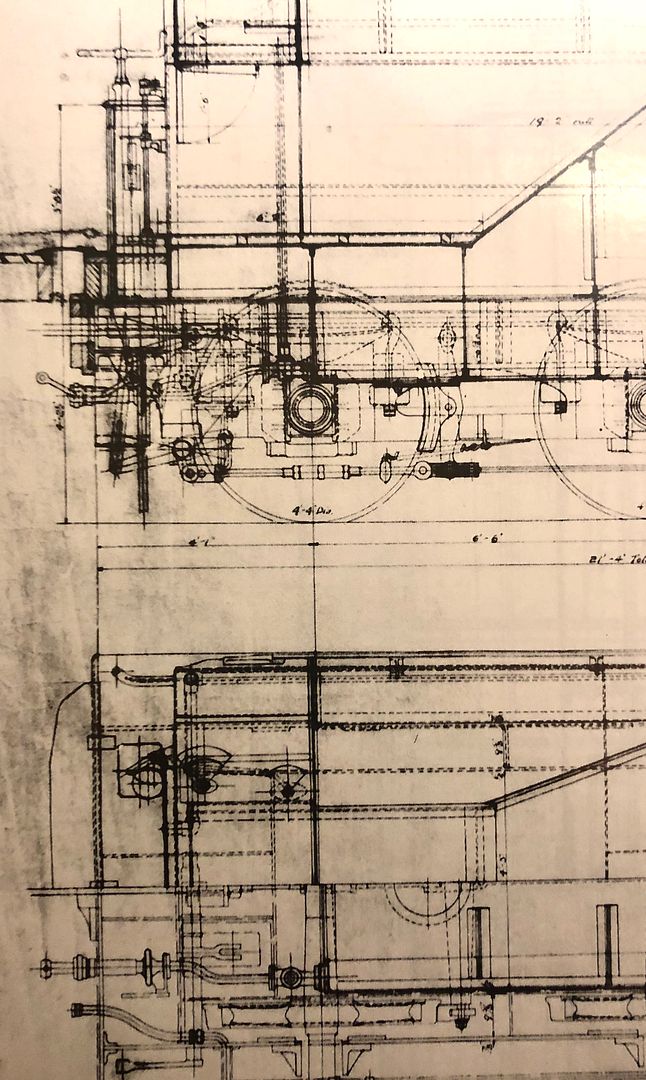

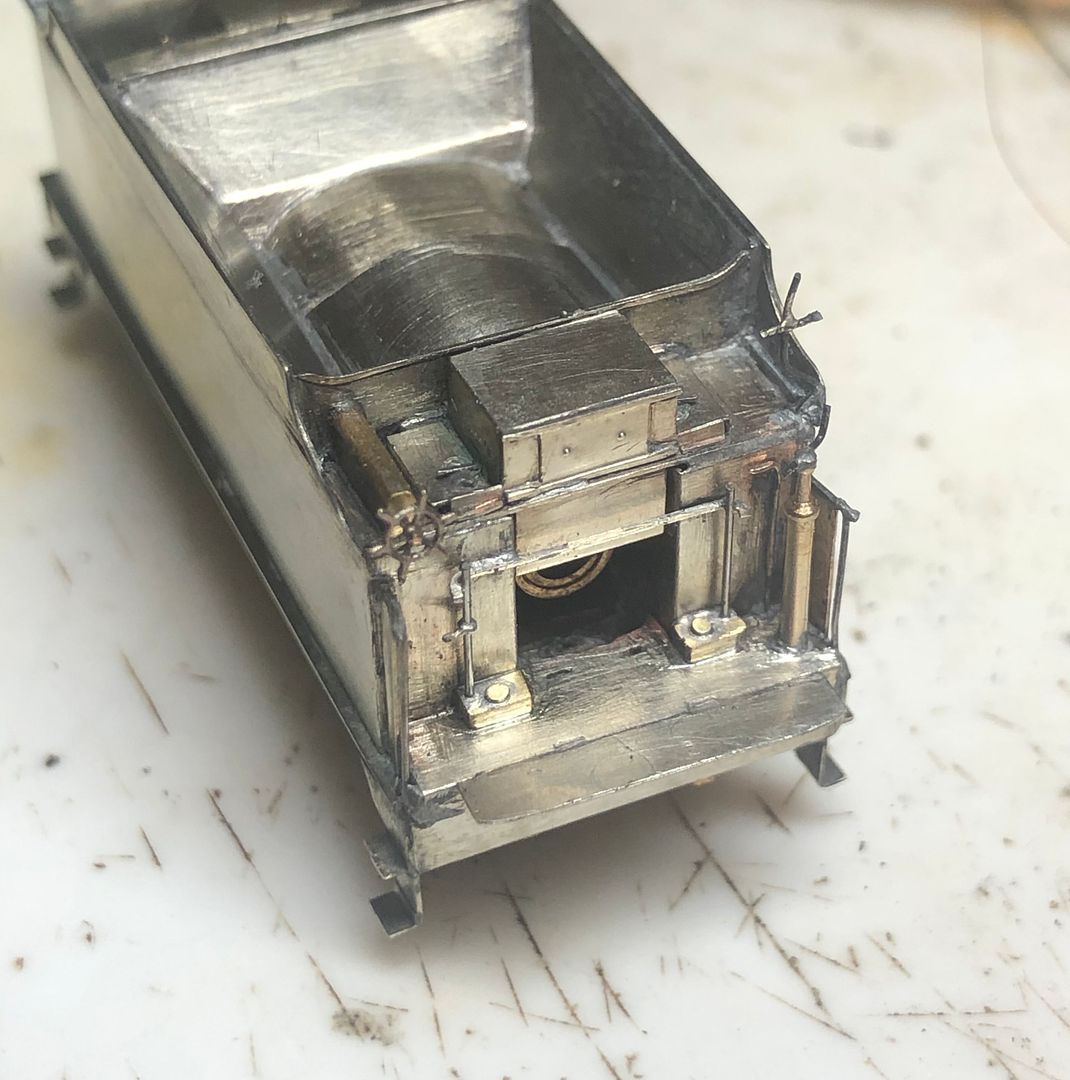

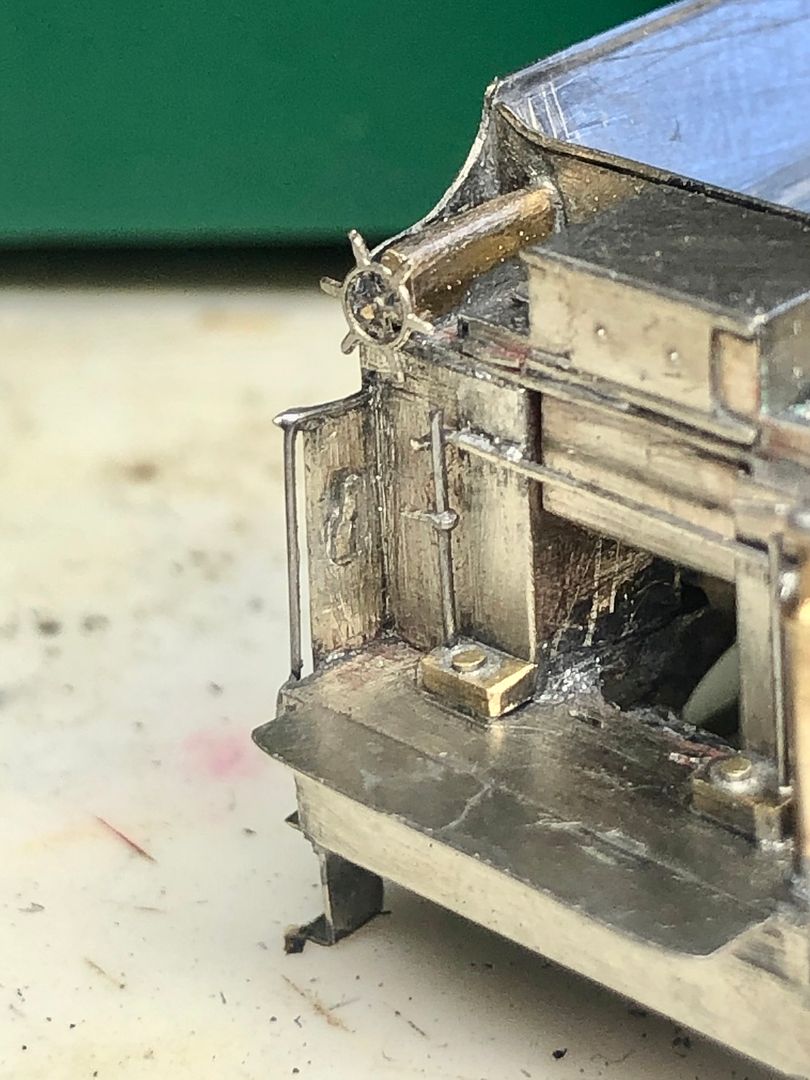

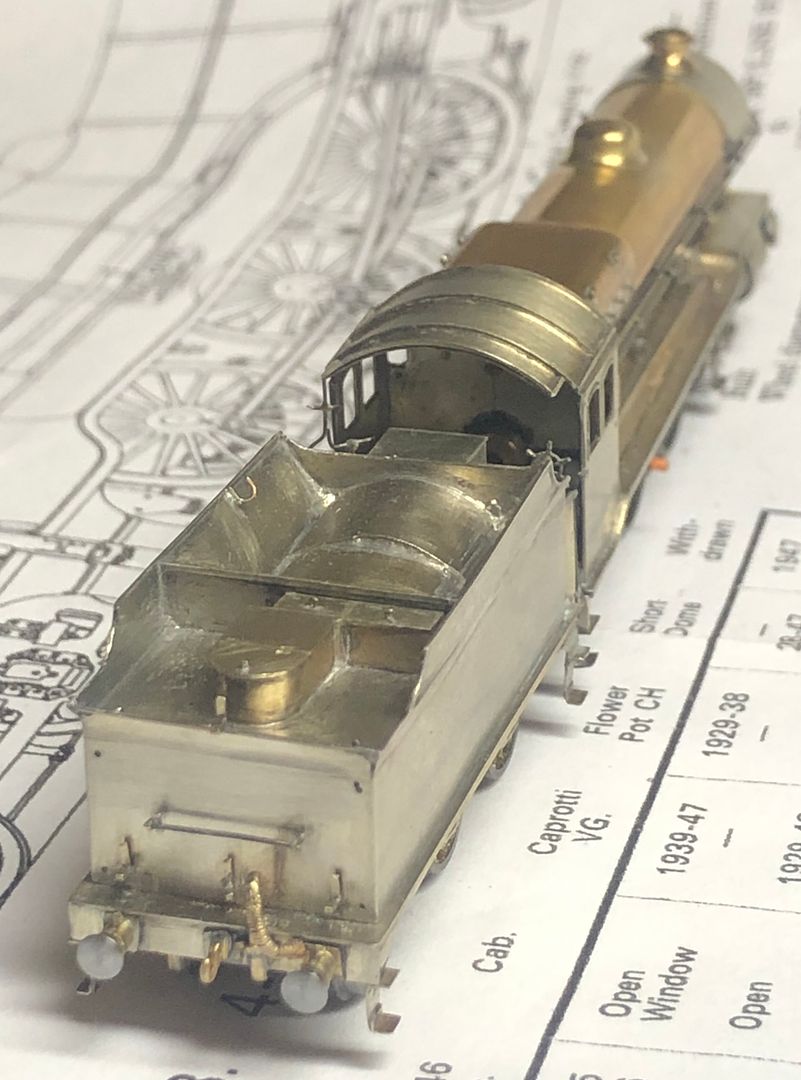

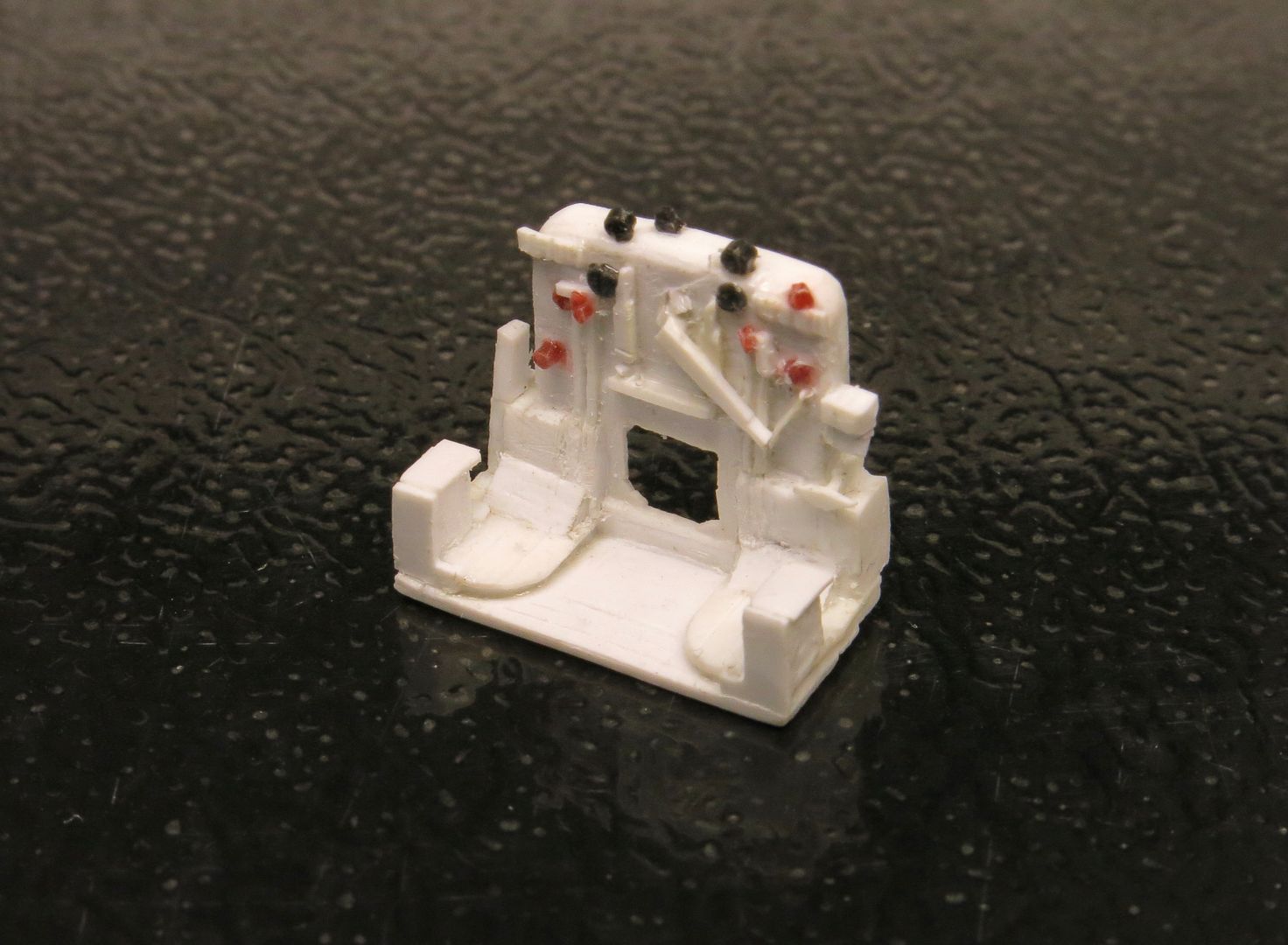

Needless to say, the Robinson engines had a very stylish hand brake column on the tender.

(Photo courtesy PAD Peter)

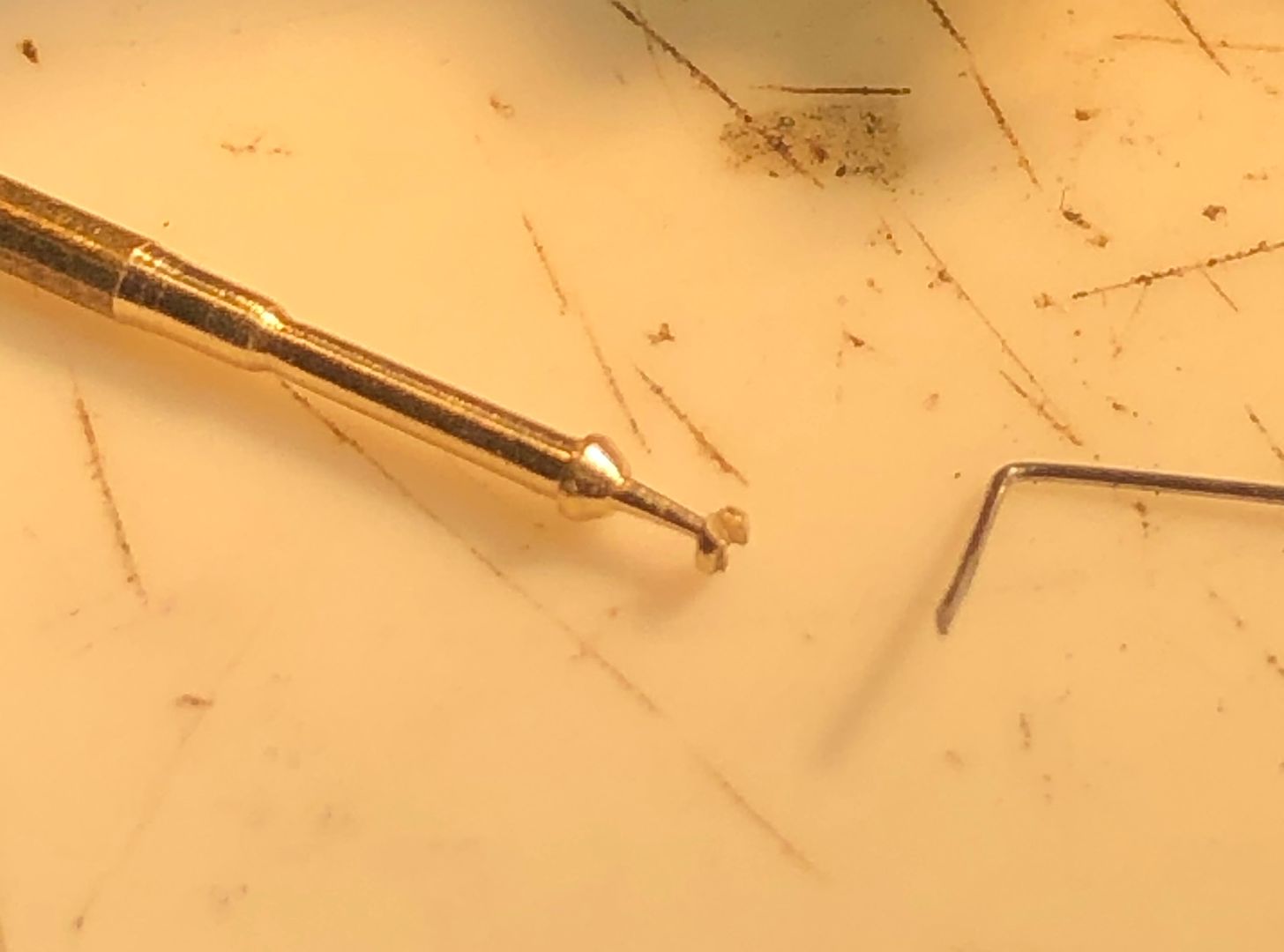

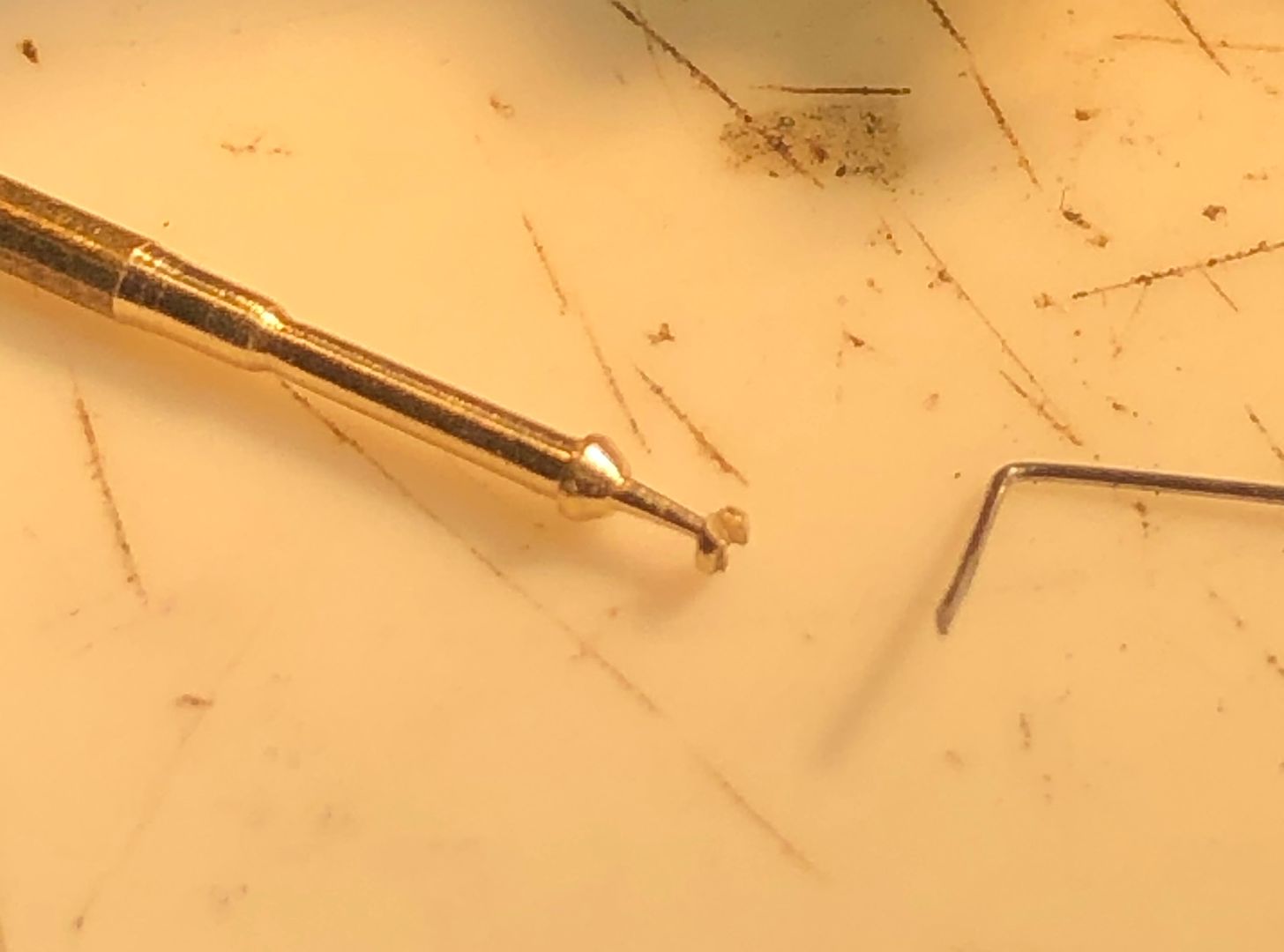

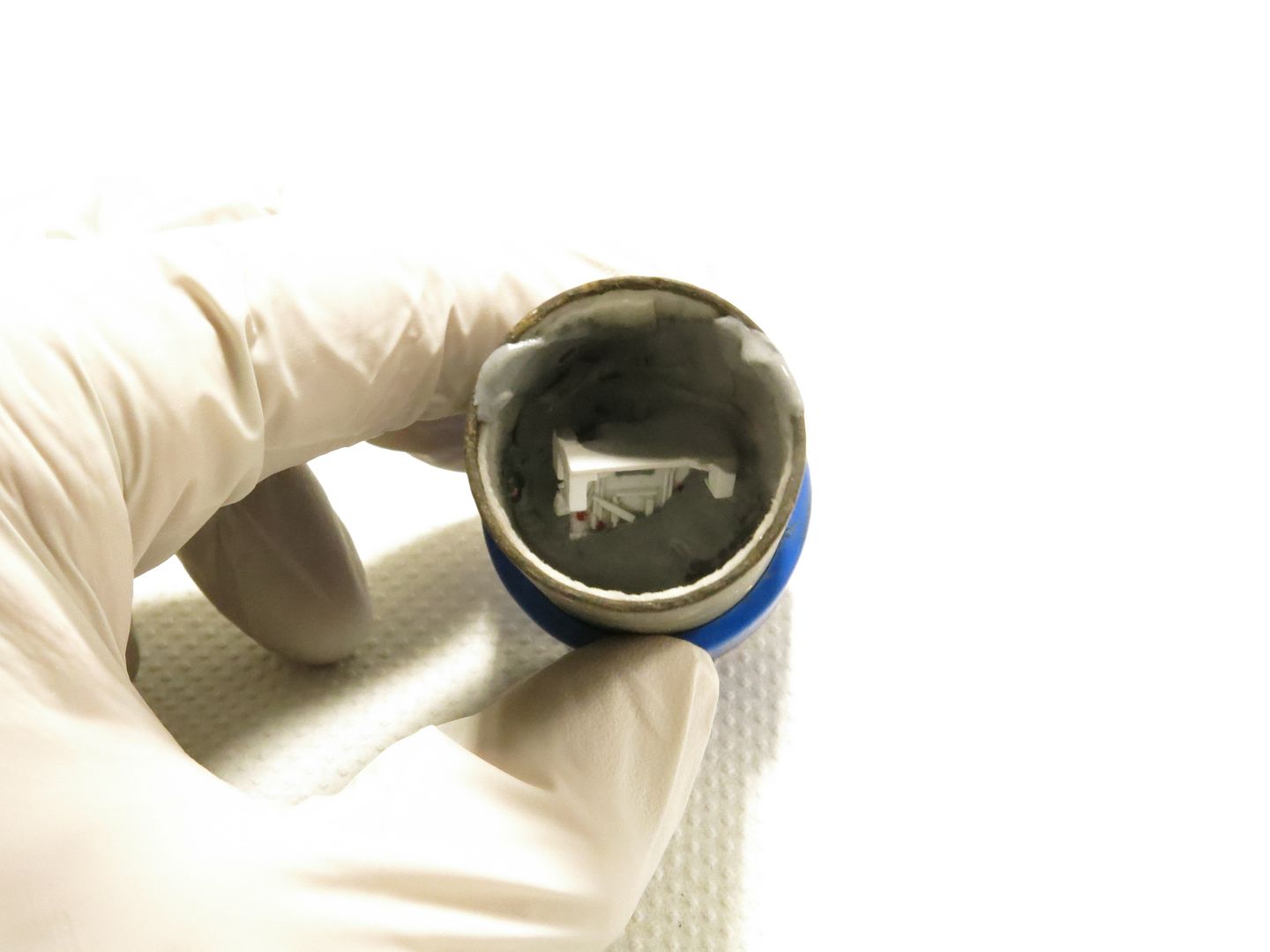

I originally played with a brass casting, but this didn’t look right: Valour has become quite a special engine, so I thought something better was needed. I therefore turned up some 1mm diameter brass rod, initially to the diameter of the head. This was grooved across the top with a slotting file.

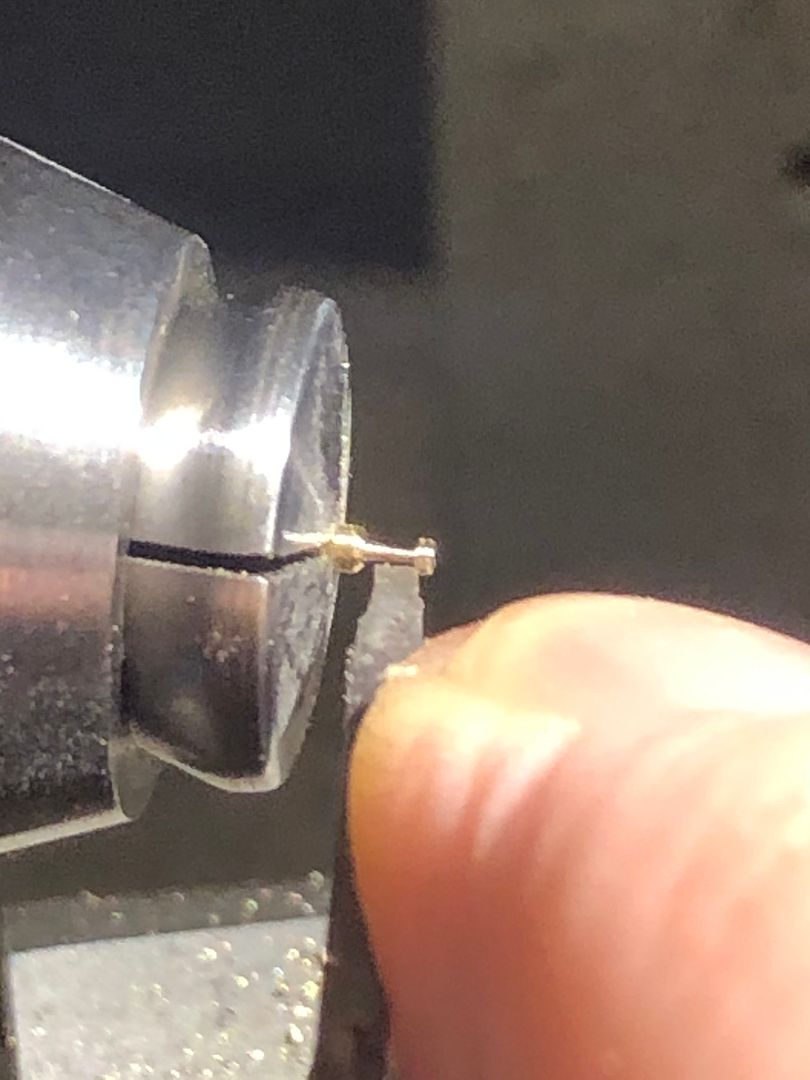

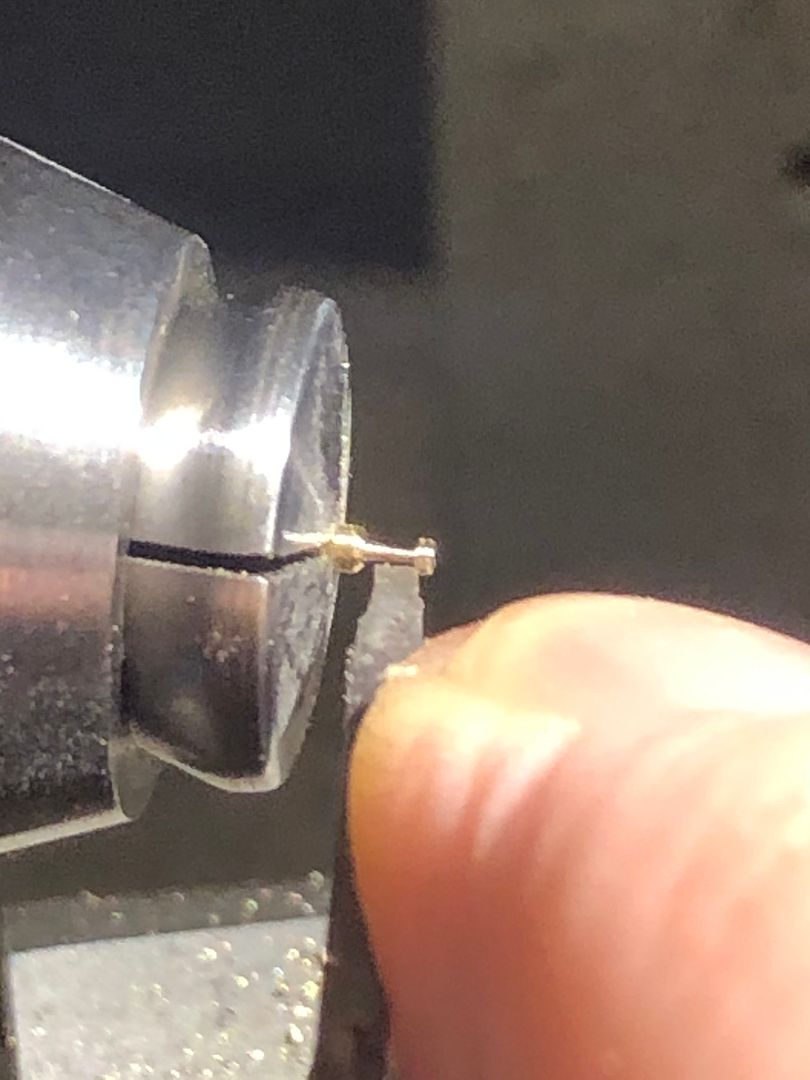

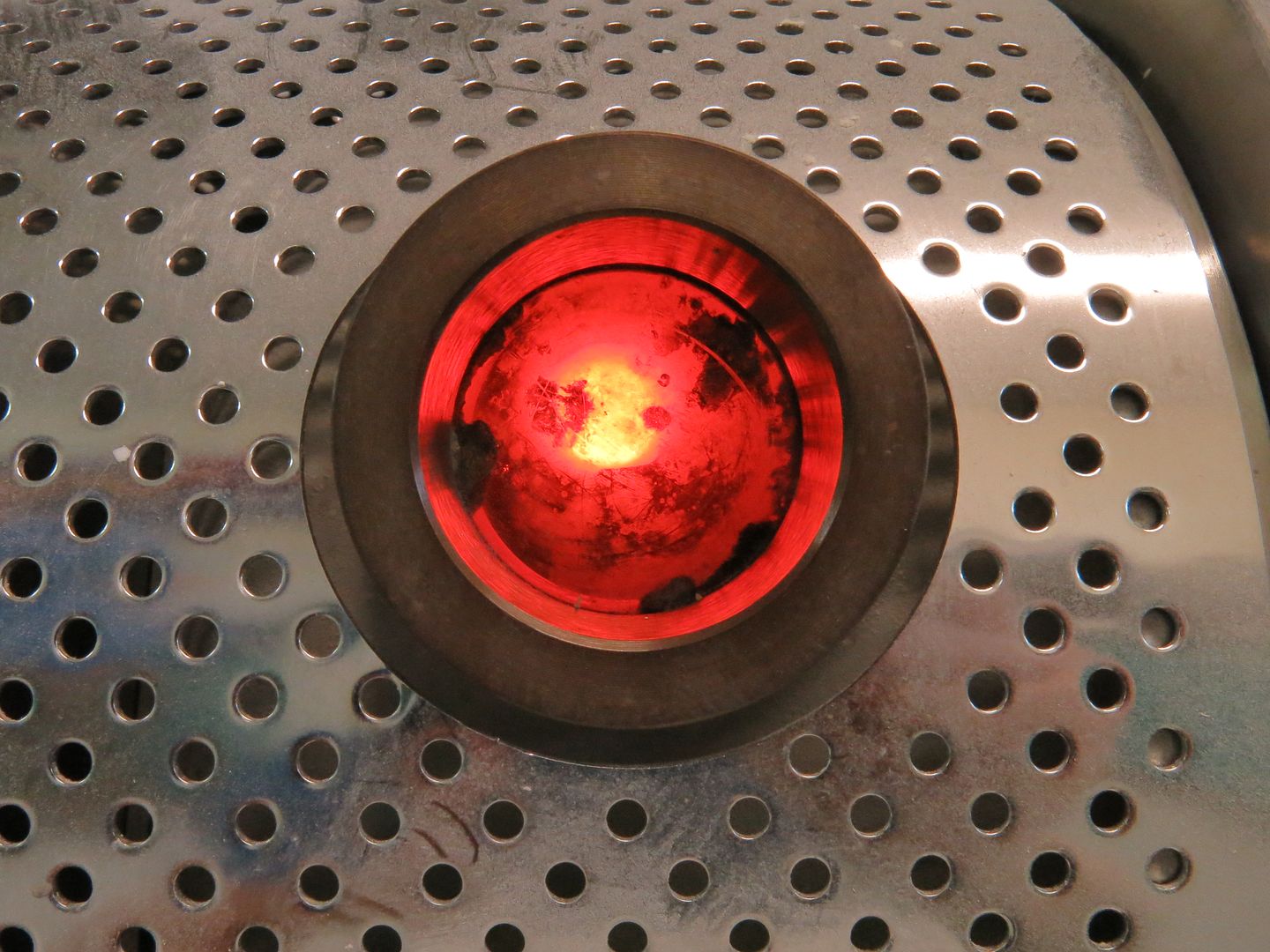

It was then put in the lathe and just the top shank of the brake rod hand turned with a graver.

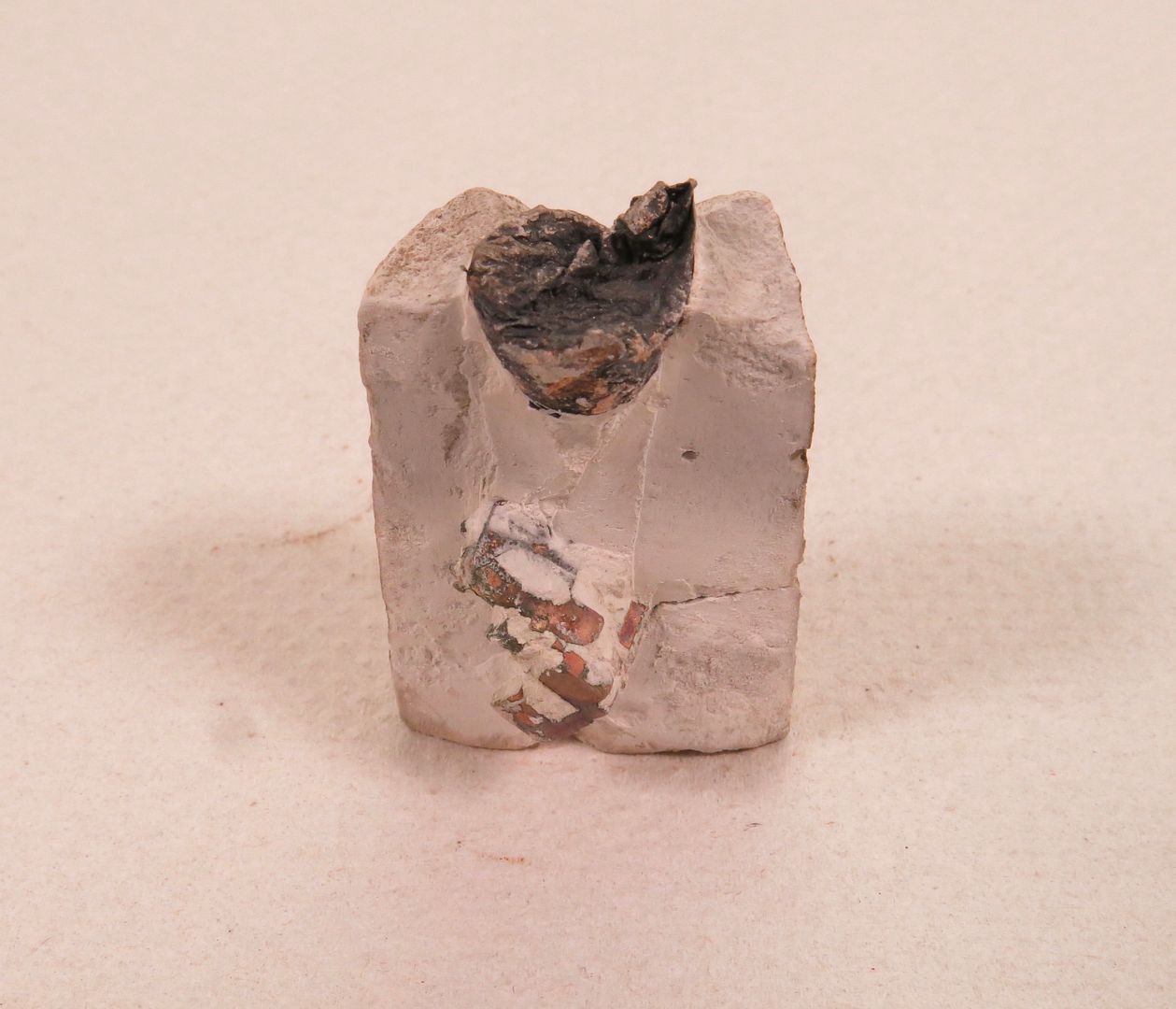

The rear of the column was then moved out of the collet and taper turned to length, finishing off with a fine file - note the finger rest when turning and the file held lightly between first finger and thumb

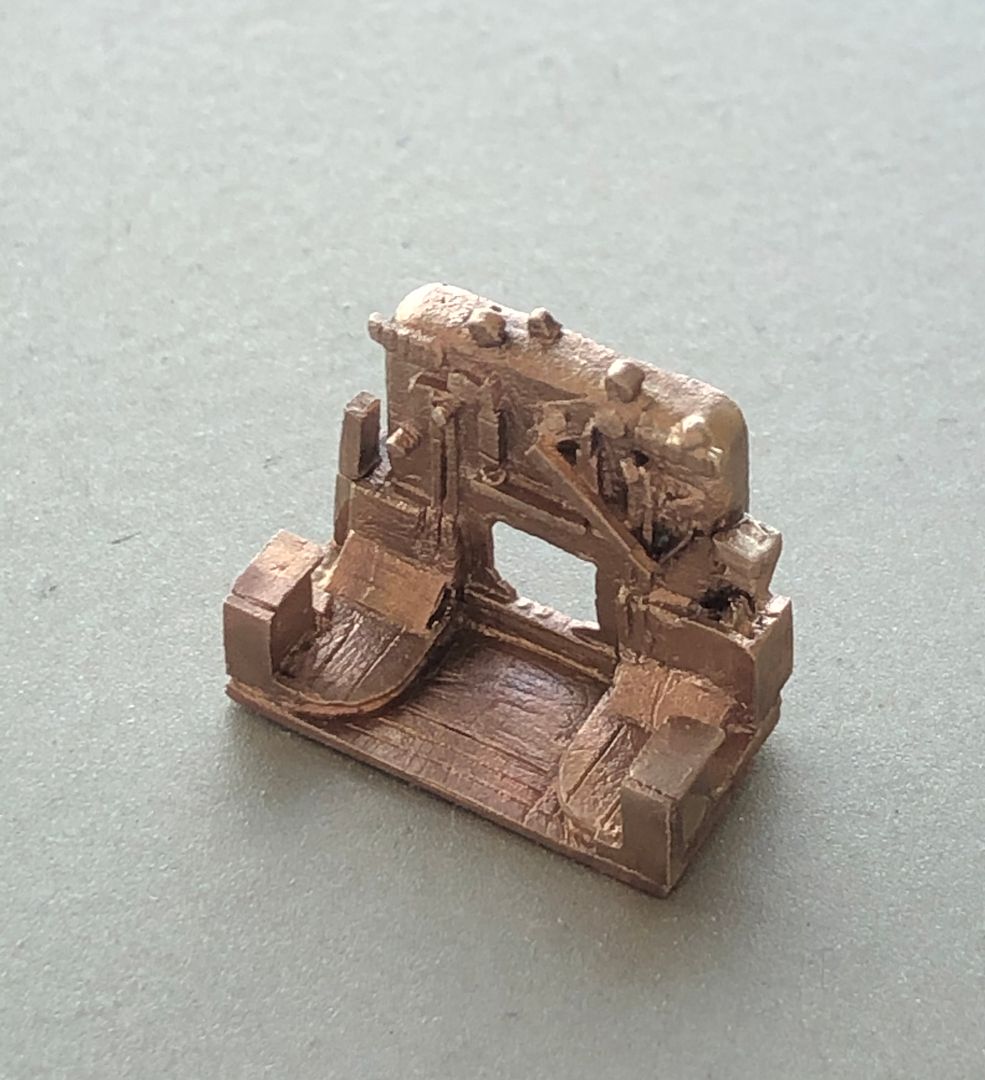

The handle was bent up from steel wire and fitted into the slot on the head.

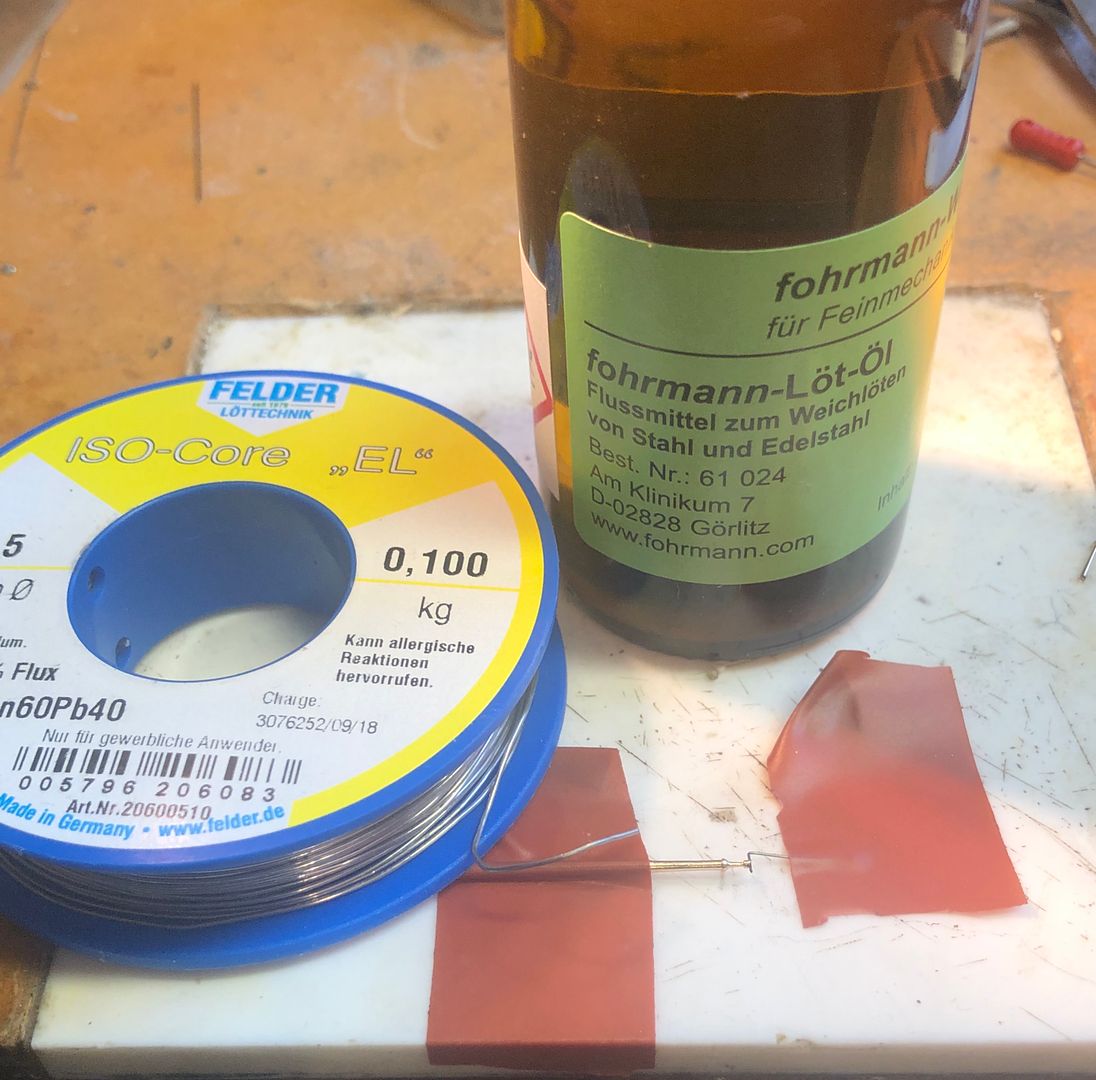

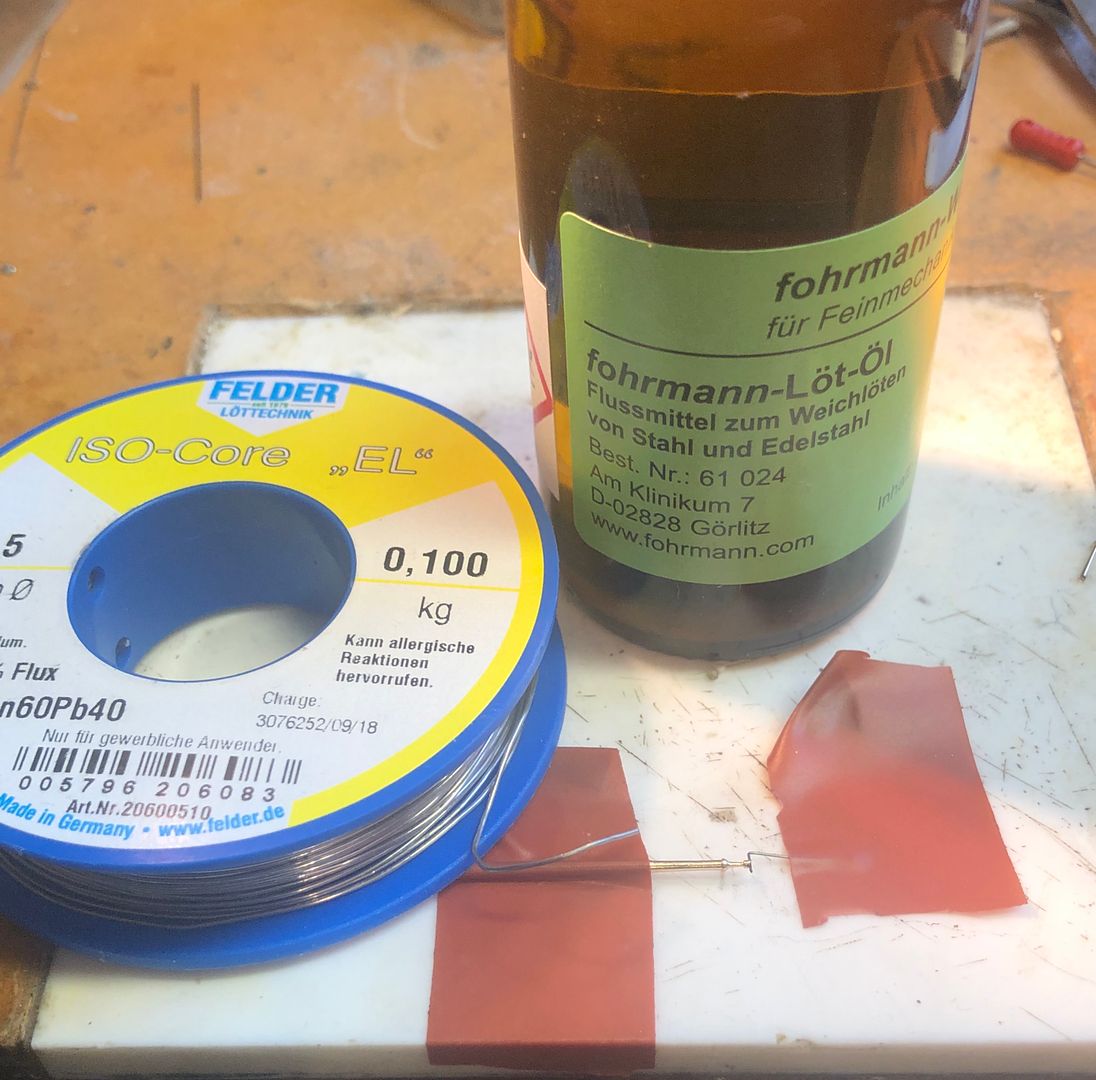

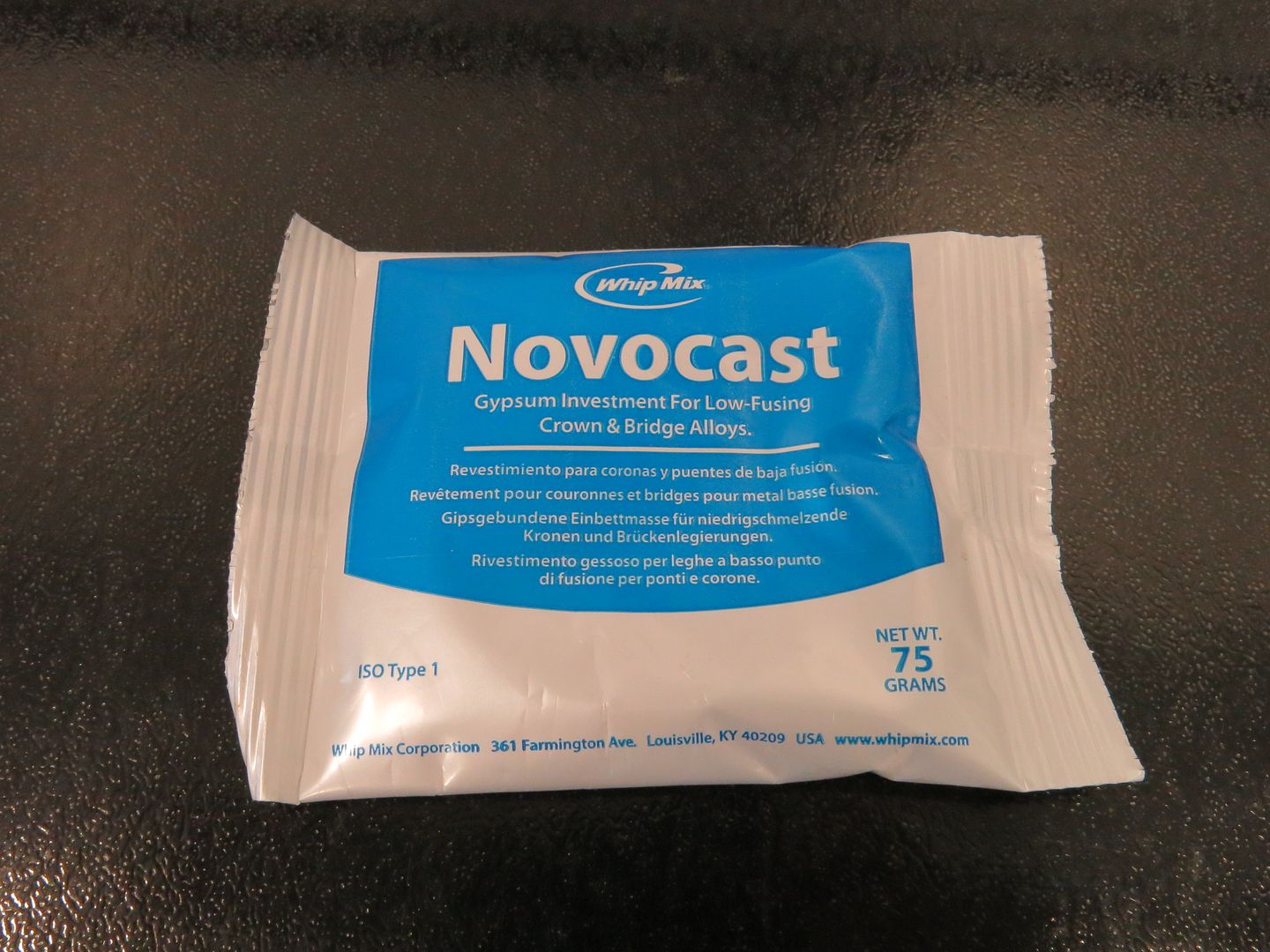

The two components were held relative to each other using insulating tape and soldered with some very good solder & flux from Germany that works well with steel fohrmann-WERKZEUGE

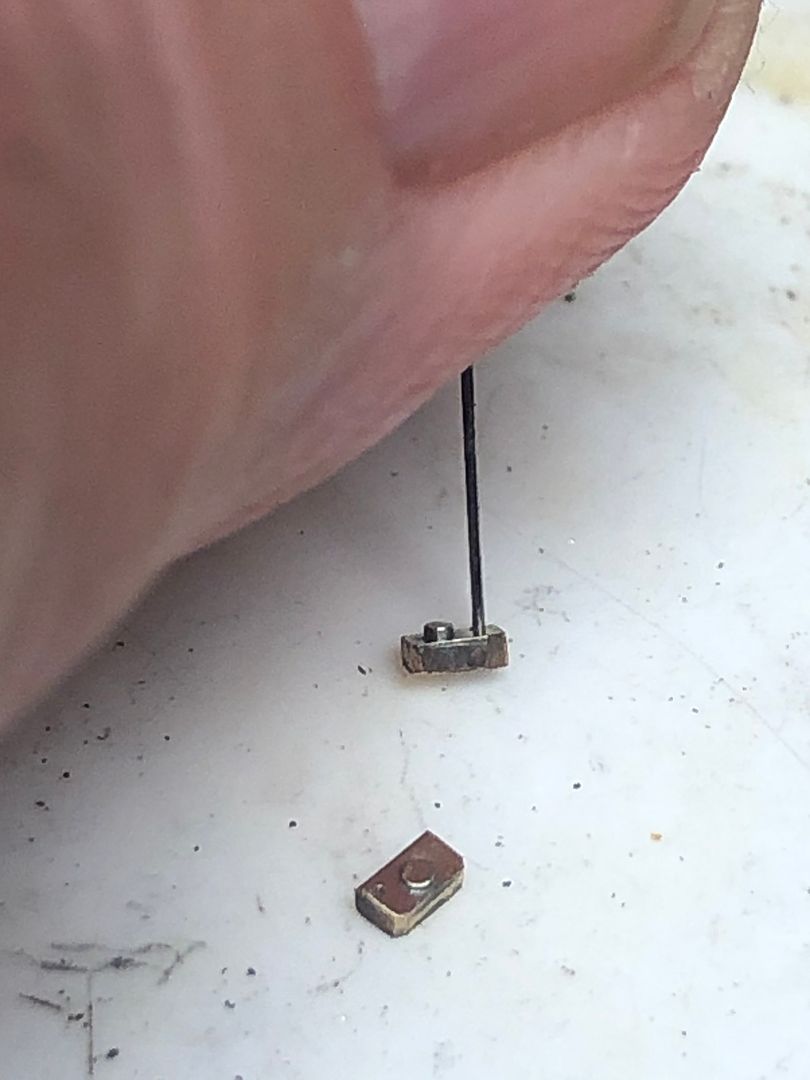

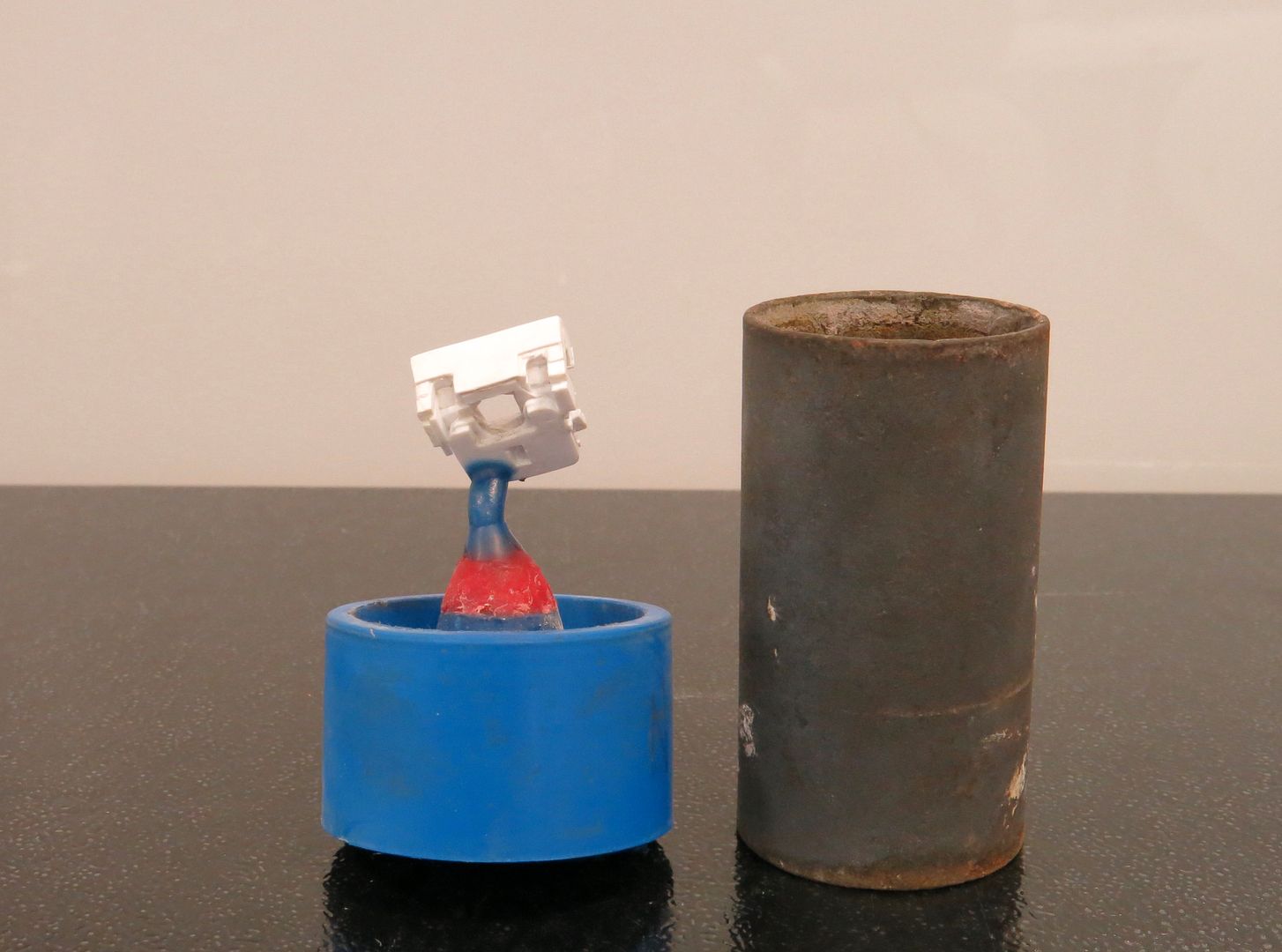

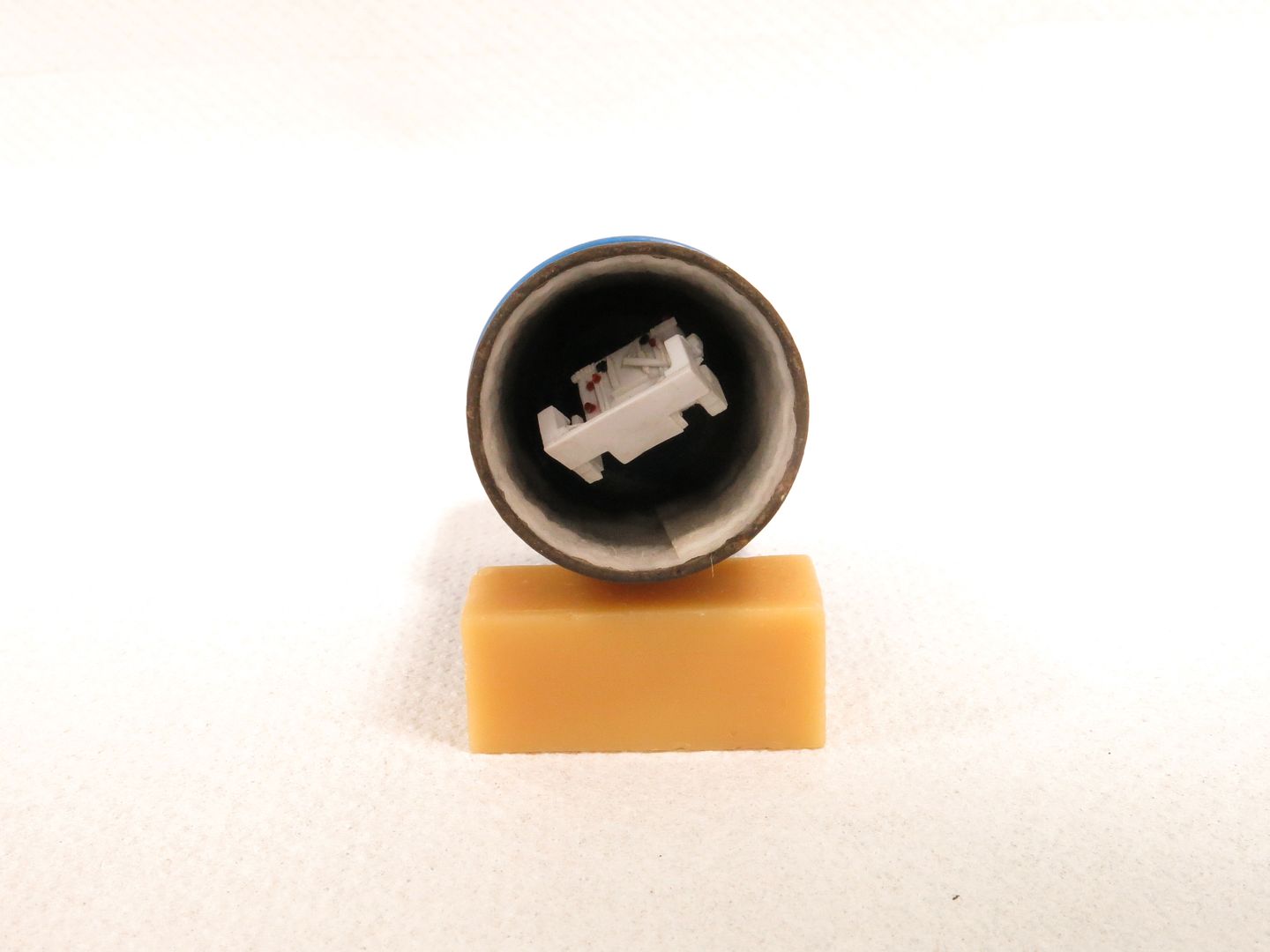

The end result (two were made) can be compared with the casting, which had been modified as much as I could. It would probably have been OK on a ‘layout’ loco. Any excess steel was cut off with a fine diamond slitting disc on the hand made column.

It was soon mounted on the tender footplate.

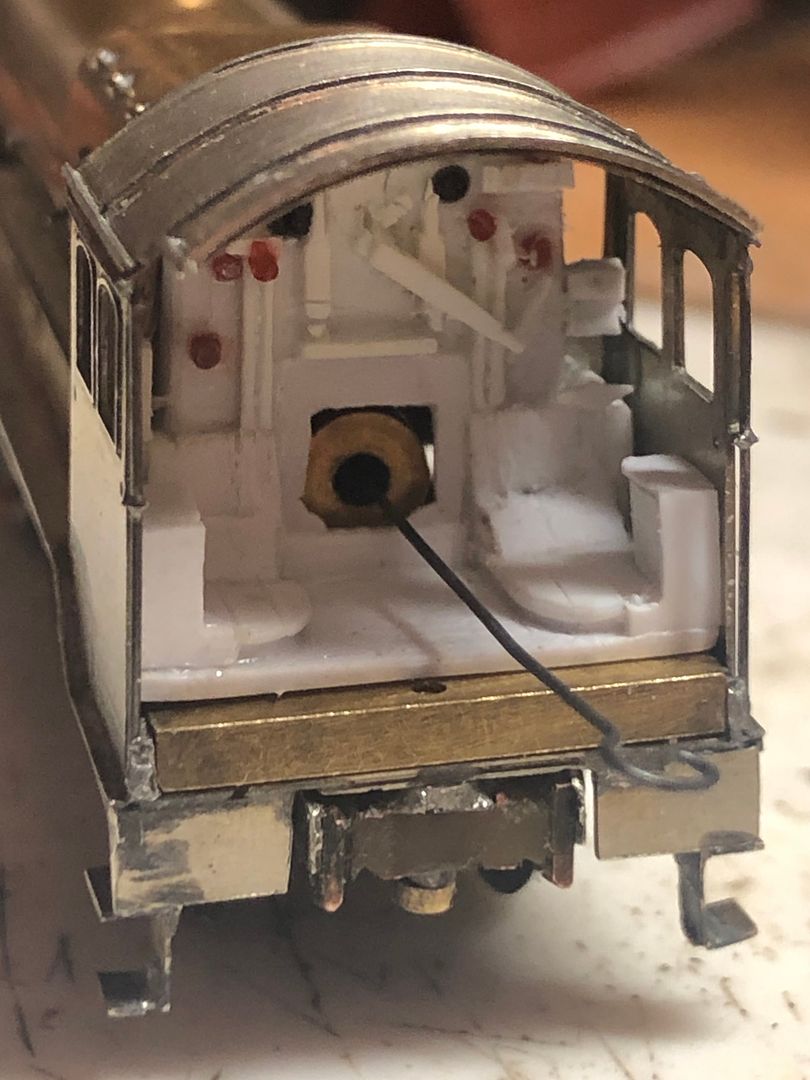

I think that almost finishes off the tender front end detailing. The cab fittings will probably have the plastic pattern made at the MEE at Ally Pally in a few weeks time.

Tim

(Photo courtesy PAD Peter)

I originally played with a brass casting, but this didn’t look right: Valour has become quite a special engine, so I thought something better was needed. I therefore turned up some 1mm diameter brass rod, initially to the diameter of the head. This was grooved across the top with a slotting file.

It was then put in the lathe and just the top shank of the brake rod hand turned with a graver.

The rear of the column was then moved out of the collet and taper turned to length, finishing off with a fine file - note the finger rest when turning and the file held lightly between first finger and thumb

The handle was bent up from steel wire and fitted into the slot on the head.

The two components were held relative to each other using insulating tape and soldered with some very good solder & flux from Germany that works well with steel fohrmann-WERKZEUGE

The end result (two were made) can be compared with the casting, which had been modified as much as I could. It would probably have been OK on a ‘layout’ loco. Any excess steel was cut off with a fine diamond slitting disc on the hand made column.

It was soon mounted on the tender footplate.

I think that almost finishes off the tender front end detailing. The cab fittings will probably have the plastic pattern made at the MEE at Ally Pally in a few weeks time.

Tim

Last edited:

I'd like to say I wasn't sure if the lamp irons were original or later additions and left them off, but I completely missed them.

I'd like to say I wasn't sure if the lamp irons were original or later additions and left them off, but I completely missed them. Its amazing what you don't see even when you look . There are two on Butler Butler Henderson so I'm wondering why you've gone with one?

Its amazing what you don't see even when you look . There are two on Butler Butler Henderson so I'm wondering why you've gone with one?

Nice work by the way.

Nice work by the way.  and the obligatory "1p" for scale comparison to judge the lunacy?

and the obligatory "1p" for scale comparison to judge the lunacy?