A friend suggested Nellie would benefit from some better buffers, and then a member of WT wrote to me with the same idea. We all seem to feel, the cast ones provided in the kit are perfectly adequate and keep the kit affordable, but better ones can be had. I have therefore indulged myself in some sprung GER style buffers from Walsall Model Engineering, and fitted these to the loco.

Taking the cast buffers off was almost too easy. Opening up the holes for the new buffers was harder and I ended up with the rear buffer beam delaminating itself. Still it was good to be able to clean it up.

The new buffers arrived with a somewhat conical shape. I understand, this is because a rounded-off convex buffer shape is difficult to make if you don't have a suitable CNC machine. So I removed the heads, covered them in black ink as a witness mark (Sharpie pen) and worked a small flat file over them.

Health and Safety people should now look DOWN to the next photo below. I put each head in the mini drill (20,000 rpm), ran the buffing wheel at half speed (5,000 rpm) and dressed the heads of the buffers. Then I treated them with Perma Blue.

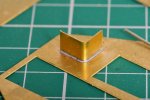

I have also treated myself to a micro flame torch. I tinned the backs of the buffer

stems bases using the iron I used for the rest of the build, and then sweated them into place with the torch. This photo rather shows how my soldering has changed since I started . . .

This is the result. Nellie is a freelance model but somehow she now has a bit of a "scale" aura about her.

I am hoping to take her to the West Essex club at Chadwell Heath tomorrow