You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A West Midlands Works

- Thread starter Scanlon

- Start date

Scanlon

Western Thunderer

The tender is almost complete with only the rear ladders to construct and to find a suitable method of fixing the vacuum and steam heat castings to the rear bufferbeam without interfering with the inner frames.

Attention has now turned to the engine frames. In places they had turned green so they were completely stripped down and thoroughly cleaned using Cif and then Barkeepers Friend, other cleaning agents are available! Once dry they were reassembled. This photo identifies using red tape the frame stretchers that were missing and which Dave Sharp has kindly sought out from his stash of old test etches.

Prior to reassembly everything was thoroughly cleaned of all old solder and the tags straightened up. The frames are now rebuilt and awaiting detailing

There are no frame overlays however 99% of the tabs will be covered up by the driving wheels or ashpan assemblies.

Attention has now turned to the engine frames. In places they had turned green so they were completely stripped down and thoroughly cleaned using Cif and then Barkeepers Friend, other cleaning agents are available! Once dry they were reassembled. This photo identifies using red tape the frame stretchers that were missing and which Dave Sharp has kindly sought out from his stash of old test etches.

Prior to reassembly everything was thoroughly cleaned of all old solder and the tags straightened up. The frames are now rebuilt and awaiting detailing

There are no frame overlays however 99% of the tabs will be covered up by the driving wheels or ashpan assemblies.

Scanlon

Western Thunderer

Work on the frames has concentrated on building the pony truck and detailing the cylinders and building up the slidebars. This kit is one of the later ones and to detail the cylinders castings are provided for the front and rear faces. These in turn are detailed with castings for the piston valve covers, front cylinder covers etc. This makes the cylinders look bulky and hope that when painted this will not be so obvious.

The crossheads and connecting rods have been built up and are ready for fitting.

Alongside this work I decided to disassemble the boiler/smokebox/cab. Removing the smokebox has revealed the fixings for bolting it down to the saddle were missing. Looking at the cab it became apparent the original build was poor but unfortunately this was one area where the previous builder had soldered everything together. As the kit is provided with a second outer “skin” I decided to bite the bullet and remove the original one and hope sufficient of the tags would remain to fit/locate the new “skin” to. I’m glad I did strip the cab because this revealed the basic frame had been built up very badly. In fact, some parts which were to be laminated were glued together rather than soldered. With the “skin” removed the opportunity has been taken to detail the inside of the cab with seats, reverser, injector controls etc. A major difficulty with the cab is getting the backhead in position once everything is in place. The height of the backhead casting has been slightly reduced and by feeding it roughly in to the left hand “corner” it was teased into place. Hopefully when it is fully detailed it will fit just as easily!

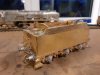

The boiler had been partially detailed but evidence of epoxy glue surrounded every fitting. All have been removed and cleaned up and the excess glue on the boiler prised off. The boiler is now detailed with most fittings refitted and all soldered in place. The engine is currently a kit of larger parts as this photo shows.

The running plate has also been detailed and is almost completed. The kit does not provide castings for the seven oil boxes. Fortunately, I have a supply from Iain Young and have used six twin feed plus one single feed boxes. I still have to add conduiting for the lighting and AWS. Covers for the main steam pipes and the sandbox chutes can only be added once the boiler is in place.

Lots more still to do.

The crossheads and connecting rods have been built up and are ready for fitting.

Alongside this work I decided to disassemble the boiler/smokebox/cab. Removing the smokebox has revealed the fixings for bolting it down to the saddle were missing. Looking at the cab it became apparent the original build was poor but unfortunately this was one area where the previous builder had soldered everything together. As the kit is provided with a second outer “skin” I decided to bite the bullet and remove the original one and hope sufficient of the tags would remain to fit/locate the new “skin” to. I’m glad I did strip the cab because this revealed the basic frame had been built up very badly. In fact, some parts which were to be laminated were glued together rather than soldered. With the “skin” removed the opportunity has been taken to detail the inside of the cab with seats, reverser, injector controls etc. A major difficulty with the cab is getting the backhead in position once everything is in place. The height of the backhead casting has been slightly reduced and by feeding it roughly in to the left hand “corner” it was teased into place. Hopefully when it is fully detailed it will fit just as easily!

The boiler had been partially detailed but evidence of epoxy glue surrounded every fitting. All have been removed and cleaned up and the excess glue on the boiler prised off. The boiler is now detailed with most fittings refitted and all soldered in place. The engine is currently a kit of larger parts as this photo shows.

The running plate has also been detailed and is almost completed. The kit does not provide castings for the seven oil boxes. Fortunately, I have a supply from Iain Young and have used six twin feed plus one single feed boxes. I still have to add conduiting for the lighting and AWS. Covers for the main steam pipes and the sandbox chutes can only be added once the boiler is in place.

Lots more still to do.

Peter Cross

Western Thunderer

A while ago I was asked to test build the new David Andrews kit for a 3 cylinder Southern N1. Here is the result

View attachment 132570

View attachment 132571

A lovely kit and I can't wait to get my hands on a production kit.

The N1 is my favourite of the Maunsell moguls.

Scanlon

Western Thunderer

It has been quite some time since I last posted anything about the various loco builds I’m working on. Unfortunately, a problem with my left wrist has cut down modelling by about 50% but I am getting there.

Firstly 30908 Westminster is now complete and awaiting the call to the paint shop.

Work continues on Merchant Navy 35008 and has now reached this stage.

Dave Sharp has yet again raided his spare test etches and supplied me with all the missing parts needed to hopefully complete the loco. As the fittings for bolting down the smokebox to the saddle had not been fitted by the original builder, reconstruction of the engine body had to proceed from the cab forwards. To ensure the running plate was at 90° to the cab I soldered short pieces of L shaped brass to the underside of the running plate and then the cab. Next the boiler was soldered to the cab followed by the smokebox. With the smokebox exactly where it should be the missing etches for fixing it to the saddle were put in place and bolted up. Once I was happy they were in their correct positions they were soldered in. Since then more detailing has been undertaken.

Alongside the Merchant Navy I have been building a Chowbent Fowler 2-6-2t. The etches are dated 1992 and it has a Premier set of frames, cylinders, rods and valve gear instead of nickel silver etches. More of this later.

The chosen locomotive is 40042 which had welded tank sides saving a lot of work. Initial construction was relatively straightforward as the running plate is built up on a frame somewhat similar to a Finney7 build. Unfortunately, any similarity ended there as the frame was not robust and very quickly began to sag. By good fortune the tank sides etc. were put in position before it finally collapsed.

As the bodywork progressed it became clear the two tank sides were not exactly the same length and considerable filing was required in places and gaps filled with solder. Having reached the above stage, I could proceed with building the boiler etc.. I had to be creative to space out the front and rear formers for the firebox and then used another “three hands” to enable soldering up.

There were no washout plugs in the kit but fortunately I found some in my spares box. I then tried the firebox in the frames, simple you would think but no. Although the cab front is located in slots they were not in the right place. There was a good 2mm gap at the top of the firebox while the bottom was level with the front etch. The cab front could not be moved as it would otherwise have been proud of the front of the cabside etches. Eventually the problem between the firebox and cab front was solved by slightly inclining the back of the firebox and now everything is correctly in position. The smokebox etch was difficult to fit mainly due to most of the unseen inside being of a very heavy gauge material which required a huge amount of heat before solder would take.

The outer etch was slightly too short so I had to add 0.4mm wire to fill the gap. Since then, progress has been quite rapid and most of the detailing is now in place.

Thoughts then turned to building the frames and this photo shows most of the parts.

With the frames basically bolted up they fitted exactly under the body but then came the problem of building up the cylinders etc.

Three of these parts are of 1.6mm thick material and the actual cylinder is a 9.5mm solid piece of round brass with machined ends to fit into the front and rear plates. Thankfully the cylinder has been drilled to take the piston rod and the piston valve rod, shown roughly in place, then the whole assembly is to be bolted to the main frames a la MOK. Unfortunately, none of my soldering equipment is able to get this mass of brass up to temperature for soldering. Fortunately a fellow builder has offered to build up the entire frame assembly. Phew!

Firstly 30908 Westminster is now complete and awaiting the call to the paint shop.

Work continues on Merchant Navy 35008 and has now reached this stage.

Dave Sharp has yet again raided his spare test etches and supplied me with all the missing parts needed to hopefully complete the loco. As the fittings for bolting down the smokebox to the saddle had not been fitted by the original builder, reconstruction of the engine body had to proceed from the cab forwards. To ensure the running plate was at 90° to the cab I soldered short pieces of L shaped brass to the underside of the running plate and then the cab. Next the boiler was soldered to the cab followed by the smokebox. With the smokebox exactly where it should be the missing etches for fixing it to the saddle were put in place and bolted up. Once I was happy they were in their correct positions they were soldered in. Since then more detailing has been undertaken.

Alongside the Merchant Navy I have been building a Chowbent Fowler 2-6-2t. The etches are dated 1992 and it has a Premier set of frames, cylinders, rods and valve gear instead of nickel silver etches. More of this later.

The chosen locomotive is 40042 which had welded tank sides saving a lot of work. Initial construction was relatively straightforward as the running plate is built up on a frame somewhat similar to a Finney7 build. Unfortunately, any similarity ended there as the frame was not robust and very quickly began to sag. By good fortune the tank sides etc. were put in position before it finally collapsed.

As the bodywork progressed it became clear the two tank sides were not exactly the same length and considerable filing was required in places and gaps filled with solder. Having reached the above stage, I could proceed with building the boiler etc.. I had to be creative to space out the front and rear formers for the firebox and then used another “three hands” to enable soldering up.

There were no washout plugs in the kit but fortunately I found some in my spares box. I then tried the firebox in the frames, simple you would think but no. Although the cab front is located in slots they were not in the right place. There was a good 2mm gap at the top of the firebox while the bottom was level with the front etch. The cab front could not be moved as it would otherwise have been proud of the front of the cabside etches. Eventually the problem between the firebox and cab front was solved by slightly inclining the back of the firebox and now everything is correctly in position. The smokebox etch was difficult to fit mainly due to most of the unseen inside being of a very heavy gauge material which required a huge amount of heat before solder would take.

The outer etch was slightly too short so I had to add 0.4mm wire to fill the gap. Since then, progress has been quite rapid and most of the detailing is now in place.

Thoughts then turned to building the frames and this photo shows most of the parts.

With the frames basically bolted up they fitted exactly under the body but then came the problem of building up the cylinders etc.

Three of these parts are of 1.6mm thick material and the actual cylinder is a 9.5mm solid piece of round brass with machined ends to fit into the front and rear plates. Thankfully the cylinder has been drilled to take the piston rod and the piston valve rod, shown roughly in place, then the whole assembly is to be bolted to the main frames a la MOK. Unfortunately, none of my soldering equipment is able to get this mass of brass up to temperature for soldering. Fortunately a fellow builder has offered to build up the entire frame assembly. Phew!

Scanlon

Western Thunderer

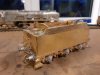

With the Fowler 2-6-2t away for the frame to be assembled work has recommenced on Merchant Navy 35008. Detailing the boiler etc. has taken up a lot of the time and now the only major items still to be added are the injectors and their associated pipework and under the opposite side of the cab the generator.

The last couple of weeks have been spent installing the brake gear, building up the cylinders, slidebars etc. and fitting the motion brackets. Inevitably the brake gear is complicated to set up but once in position it is very satisfying. This photo shows the entire assembly in place.

The outer pull rods on each side are removeable for the moment to allow the wheels to be easily taken out.

Next to be installed has been the cylinders, slidebars and connecting rods. The instructions say to use 2mm steel rod for the piston rods, however I have substituted 1.6mm rod as it looks somewhat better. The slidebar components are superb.

Setting up was very straightforward with very minimal cleaning needed. 0.5 wire was used to pin everything together and they worked first time. The piston rod was cut to length and put into the piston gland and then soldered into the crosshead. Very slight adjustment was required to get the entire assembly to work without any problem.

Setting up was very straightforward with very minimal cleaning needed. 0.5 wire was used to pin everything together and they worked first time. The piston rod was cut to length and put into the piston gland and then soldered into the crosshead. Very slight adjustment was required to get the entire assembly to work without any problem.

The motion brackets were then installed and the drain cocks added to the cylinders.

The frames have been thoroughly tested on my test track which is an S curve with 6ft radii. Initially both the bogie and pony truck tended to derail. The frames were run in 4-6-0 and 0-6-2 modes and a problem with the pony truck identified. The inside edges of the ashpan hoppers were filed down and a small amount of the pony truck casting was ground out where it was touching the underside of the rear of the ashpan towards to the cab. Everything was retested and I now have a free-flowing frame which can be stripped for painting and then the valve gear installed.

35008 has now reached this stage

Lots still to do not least cleaning!

The last couple of weeks have been spent installing the brake gear, building up the cylinders, slidebars etc. and fitting the motion brackets. Inevitably the brake gear is complicated to set up but once in position it is very satisfying. This photo shows the entire assembly in place.

The outer pull rods on each side are removeable for the moment to allow the wheels to be easily taken out.

Next to be installed has been the cylinders, slidebars and connecting rods. The instructions say to use 2mm steel rod for the piston rods, however I have substituted 1.6mm rod as it looks somewhat better. The slidebar components are superb.

Setting up was very straightforward with very minimal cleaning needed. 0.5 wire was used to pin everything together and they worked first time. The piston rod was cut to length and put into the piston gland and then soldered into the crosshead. Very slight adjustment was required to get the entire assembly to work without any problem.

Setting up was very straightforward with very minimal cleaning needed. 0.5 wire was used to pin everything together and they worked first time. The piston rod was cut to length and put into the piston gland and then soldered into the crosshead. Very slight adjustment was required to get the entire assembly to work without any problem.The motion brackets were then installed and the drain cocks added to the cylinders.

The frames have been thoroughly tested on my test track which is an S curve with 6ft radii. Initially both the bogie and pony truck tended to derail. The frames were run in 4-6-0 and 0-6-2 modes and a problem with the pony truck identified. The inside edges of the ashpan hoppers were filed down and a small amount of the pony truck casting was ground out where it was touching the underside of the rear of the ashpan towards to the cab. Everything was retested and I now have a free-flowing frame which can be stripped for painting and then the valve gear installed.

35008 has now reached this stage

Lots still to do not least cleaning!

Scanlon

Western Thunderer

Work on the MOK Merchant Navy has reached the stage where I’m waiting for the weather to improve so the engine frames can be sprayed.

In the meantime, I am working on two of Richard Maunsell’s locos. The first is a model of 30850 Lord Nelson from the Sans Pareil kit, the other is a “standard” U class mogul from the David Andrews kit. As detailed build descriptions of both these kits appear elsewhere in this thread, I will only post the occasional photo.

The tender for Lord Nelson has reached this stage where 95% of the etches have been assembled.

The next stage will be to add all the lost wax detail before proceeding on to the engine. Unfortunately, progress will be delayed as the frame etches are missing and they will take a little while to replace.

Consequent of the frames problem I have started to build what I describe as a “standard” U class mogul. As you may have noticed I have a soft spot for the Maunsell moguls but within my own collection I do not have one with the 4000-gallon tender. The model will be of 31639 which along with 31791 were the last SR U class moguls in service.

Here is the tender

Work has now started on the engine and the frames have been built using my chassis jig.

This photo shows my workbench which is taking on the appearance of a min replica of Eastleigh works.

Apologies for the poor quality of the photographs, I'm having trouble with my Canon G12 and need to find a decent replacement. Anyone got a recommendation for its replacement?

In the meantime, I am working on two of Richard Maunsell’s locos. The first is a model of 30850 Lord Nelson from the Sans Pareil kit, the other is a “standard” U class mogul from the David Andrews kit. As detailed build descriptions of both these kits appear elsewhere in this thread, I will only post the occasional photo.

The tender for Lord Nelson has reached this stage where 95% of the etches have been assembled.

The next stage will be to add all the lost wax detail before proceeding on to the engine. Unfortunately, progress will be delayed as the frame etches are missing and they will take a little while to replace.

Consequent of the frames problem I have started to build what I describe as a “standard” U class mogul. As you may have noticed I have a soft spot for the Maunsell moguls but within my own collection I do not have one with the 4000-gallon tender. The model will be of 31639 which along with 31791 were the last SR U class moguls in service.

Here is the tender

Work has now started on the engine and the frames have been built using my chassis jig.

This photo shows my workbench which is taking on the appearance of a min replica of Eastleigh works.

Apologies for the poor quality of the photographs, I'm having trouble with my Canon G12 and need to find a decent replacement. Anyone got a recommendation for its replacement?

Brian McKenzie

Western Thunderer

I'm having trouble with my Canon G12 and need to find a decent replacement. Anyone got a recommendation for its replacement?

I used a Canon G12 - and liked it - until it gave up. Replaced it with a Canon G7X (and for some reason now forgotten, chose that model rather than the slightly updated version G7X II). It has a slightly larger sensor than the G12 - which doesn't help depth of field when used closeup, but this is still much greater than offered by larger sensors ranging up to the so called 'full frame' size. Also, the viewing screen has less 'swing-out' capability than the G12.

What I didn't like about it for a time was that it's small size made it hard to hang on to, when used at awkward angles, without fingers inadvertently pushing buttons or options on the touch screen. I've got used to it now and would buy another. I use it mostly in Aperture mode set at F7.1 with ASA at 1600. Also take lots of video, always with manual focus set, using the very useful 'MF Peaking' facility, which displays red lines (on the screen only) to all the edges in view that are in focus.

I hate camera menus, but it is worth finding those options for this model - and always buy a spare battery

.

.Scanlon

Western Thunderer

My David Andrews U class mogul is almost finished and awaits stripping of the frames for them to be sprayed. Once that is completed I’ll install plunger pick-ups and erect the valve gear. Currently this is the condition of the loco, AWS fittings have now been installed..

This is a standard build with the exception that a BR Standard Class 4 chimney has been fitted.

My hiatus with commission builds continues so I have kept myself busy by building an MOK Standard Tank. In-depth builds of these kits have been aired elsewhere on Western Thunder particularly by Dibateg and PAD and I’m following their work closely. My thanks to Peter for his help with supplementary build photos especially with regard to the installation of pick-ups. My model will be of loco 80015 as working from Tunbridge Wells West in the mid to late 1950’s and at this period did not have a speedo or AWS.

Before commencing the build, I thoroughly studied the build booklet and then decided to follow them as closely as possible. Construction of the frames was relatively straightforward and was completed in a day.

The springs and hanger castings are almost an exact replica of the real fittings. I decided to do a test fit on the leading couple axle and when satisfied with the installation the other two axles were dealt with. This was followed by construction of the bogie and pony truck. Work then concentrated on the cylinders, slidebars etc. This is where I have chosen to diverge from the build instructions. For now I have only installed the side rods and connecting rods, piston rods will be fitted soon.

I am now at the stage where various modules are taking shape. First the boiler and smokebox was assembled including washout plugs, support for the clack valves and the regulator valve.

This was followed by construction of the smokebox saddle area and front bufferbeam. Some detailing has been added but the lubricators and their associated rodding and pipework will be fitted once the basic body is complete.

Today work has centered on building the inner framework etc. for the bunker. At first the instructions seemed complicated but following them closely step by step everything fitted perfectly.

and

Now to start construction of the side tanks and cab. If I thought the bunker was complicated the side tank construction is going to be very interesting.

This is a standard build with the exception that a BR Standard Class 4 chimney has been fitted.

My hiatus with commission builds continues so I have kept myself busy by building an MOK Standard Tank. In-depth builds of these kits have been aired elsewhere on Western Thunder particularly by Dibateg and PAD and I’m following their work closely. My thanks to Peter for his help with supplementary build photos especially with regard to the installation of pick-ups. My model will be of loco 80015 as working from Tunbridge Wells West in the mid to late 1950’s and at this period did not have a speedo or AWS.

Before commencing the build, I thoroughly studied the build booklet and then decided to follow them as closely as possible. Construction of the frames was relatively straightforward and was completed in a day.

The springs and hanger castings are almost an exact replica of the real fittings. I decided to do a test fit on the leading couple axle and when satisfied with the installation the other two axles were dealt with. This was followed by construction of the bogie and pony truck. Work then concentrated on the cylinders, slidebars etc. This is where I have chosen to diverge from the build instructions. For now I have only installed the side rods and connecting rods, piston rods will be fitted soon.

I am now at the stage where various modules are taking shape. First the boiler and smokebox was assembled including washout plugs, support for the clack valves and the regulator valve.

This was followed by construction of the smokebox saddle area and front bufferbeam. Some detailing has been added but the lubricators and their associated rodding and pipework will be fitted once the basic body is complete.

Today work has centered on building the inner framework etc. for the bunker. At first the instructions seemed complicated but following them closely step by step everything fitted perfectly.

and

Now to start construction of the side tanks and cab. If I thought the bunker was complicated the side tank construction is going to be very interesting.

dibateg

Western Thunderer

Looking good Roger -

the most difficult bit is fitting the castings to the bottoms of the tanks. When it comes to blending in the join ( 'cos it's right where the lining goes ) I avoided filing as mush as possible and used emery sticks of reducing grit to get a good finish.

As you know the early ones have a different vent arrangement, I hope you don't mind me posting this of 80016:-

Regards

Tony

the most difficult bit is fitting the castings to the bottoms of the tanks. When it comes to blending in the join ( 'cos it's right where the lining goes ) I avoided filing as mush as possible and used emery sticks of reducing grit to get a good finish.

As you know the early ones have a different vent arrangement, I hope you don't mind me posting this of 80016:-

Regards

Tony

Scanlon

Western Thunderer

Hi Tony,

Thanks for your posting, the photo is very helpful and any advice is welcome.

So what a difference a day makes, my model is beginning to look like an engine although not up to the standard of some builders. Construction of the tanks is quite involved so I read the instructions and then referred to PAD’s (Peter’s) description of how he built them. I’m glad I followed them as the large photos and fully described step by step process made assembly straightforward. This shows the basic framework attached to the front of the cab. At this stage nothing is soldered up other than the cab front assembly.

The next stage was to fit the outer framing which includes attaching the rear of the cab and bunker.

Peter suggested putting the frames on glass at this stage to make sure everything was level and then to start soldering up only the inner parts of the framing. I did this while the frame was upside down and still on glass to minimise any chance of twisting.The outer frame was then taken off and using a “Hold and Fold” the top of the tank was folded over and then reinstated. Fitting the front cab window is tricky as they had to be clicked into position to get a perfect fit. The left hand tank top also required drilling before refitting to accommodate the tank vent.

Peter suggested putting the frames on glass at this stage to make sure everything was level and then to start soldering up only the inner parts of the framing. I did this while the frame was upside down and still on glass to minimise any chance of twisting.The outer frame was then taken off and using a “Hold and Fold” the top of the tank was folded over and then reinstated. Fitting the front cab window is tricky as they had to be clicked into position to get a perfect fit. The left hand tank top also required drilling before refitting to accommodate the tank vent.

As can be seen a very rigid frame is the end result. A great number of tabs had to be filed off or ground off but all the blemishes will be covered by the outer skin. Like other builders I couldn’t resist putting the parts together and the hard work is starting to resemble a Standard tank.

Thanks Peter and Tony for your help.

Thanks for your posting, the photo is very helpful and any advice is welcome.

So what a difference a day makes, my model is beginning to look like an engine although not up to the standard of some builders. Construction of the tanks is quite involved so I read the instructions and then referred to PAD’s (Peter’s) description of how he built them. I’m glad I followed them as the large photos and fully described step by step process made assembly straightforward. This shows the basic framework attached to the front of the cab. At this stage nothing is soldered up other than the cab front assembly.

The next stage was to fit the outer framing which includes attaching the rear of the cab and bunker.

Peter suggested putting the frames on glass at this stage to make sure everything was level and then to start soldering up only the inner parts of the framing. I did this while the frame was upside down and still on glass to minimise any chance of twisting.The outer frame was then taken off and using a “Hold and Fold” the top of the tank was folded over and then reinstated. Fitting the front cab window is tricky as they had to be clicked into position to get a perfect fit. The left hand tank top also required drilling before refitting to accommodate the tank vent.

Peter suggested putting the frames on glass at this stage to make sure everything was level and then to start soldering up only the inner parts of the framing. I did this while the frame was upside down and still on glass to minimise any chance of twisting.The outer frame was then taken off and using a “Hold and Fold” the top of the tank was folded over and then reinstated. Fitting the front cab window is tricky as they had to be clicked into position to get a perfect fit. The left hand tank top also required drilling before refitting to accommodate the tank vent.

As can be seen a very rigid frame is the end result. A great number of tabs had to be filed off or ground off but all the blemishes will be covered by the outer skin. Like other builders I couldn’t resist putting the parts together and the hard work is starting to resemble a Standard tank.

Thanks Peter and Tony for your help.