Since my last posting there has been quite some developments in the “Works”. I decided the part completed locos had to be finished and moved off the bench. I allocated a week each to complete the U and the Merchant Navy. The U presented little in the way of challenges, the frames were sprayed then everything reinstalled and the valve gear built up. All was well and here is a photo of the loco just prior to go into the box waiting paint.

The Merchant Navy was never going to be as fast and eventually it took two weeks to complete. I thought the loco was almost finished but on taking a closer look I could see quite a lot needed finishing off. The tender required the rear steps building, a job I heartily dislike doing, plus a few odd jobs.

On the engine all the outstanding work was concentrated on the frames. Once they had been sprayed and wheels reinstated installation of the valve gear commenced. The castings required little in the way of fettling although I do find the material used is quite “pliable”.

Any pacific presents problems but the brake pull rods on a Bulleid make life doubly difficult. To give adequate clearance the inside rods are soldered onto the springs, you’d never know with the wheels in place. The outer rods have been bushed outwards using tiny etches provided in the kit. The other problem is setting up the brake blocks. With everything seemingly in place testing of the frames commenced and the only issue arose with the bogie shorting out.

As mentioned previously this was a part built loco I had bought at a Guild show. Unfortunately, the previous builder had opened up the bogie pin mount allowing a lot of slop to develop. Why??? Anyway, I have shimmed the pin and got rid of most of the unwanted fore/aft movement. There is very occasional shorting which I’ll have to resolve once the loco can be run on a layout instead of my test track. This problem never arose with the other MOK Merchant I built but that’s probably down to luck. Here is the loco just before it too went into its box.

So what of other builds? Well, the Fowler 2-6-2t is ready for the paint shop. The frames were built by Dan Haines and thoroughly tested. With the model back on the bench final detailing was completed and this loco is also in a box waiting paint.

The basket case U class mogul I took on last year to rebuild has just been returned from Ian Rathbone and looks a million dollars. Considering the awful state of the original build I am very pleased with the result. It is not to the standard of my U shown above but it can now hold its head up high. Very little needs to be done to complete this challenge, the boiler backplate to fit, a front coupling to install and coal in the tender. The loco will get a big load of coal to mask some of the butchering done by the first builder!!!!!

The loco will shortly be off to its new home once the present Covid restrictions are eased again.

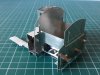

With all this work completed the only loco on my bench is the MOK Standard tank which has reached this stage, note the chimney, dome and smokebox door are only in place for effect!!!!

Blending in the side tanks is ongoing. I took council from Ian Rathbone regarding filling the inevitable joints and he recommended using a Halfords filler. At my local store they recommended using Impa Finissage, an Italian ultra-fine filler and first results on the drivers side tank are positive.

The bunker has been detailed and now only requires lamp irons. Before the boiler and firebox were installed the tank tops were detailed. 80015 was fitted with water softening from new and Ragstone have a fine casting for the 9F and Britannia which will do nicely, so a call will shortly be made to buy one. With the boiler and firebox in place the tank straps were added. Prior to soldering the front framing to the smokebox the lubricators along with their pipework were added. With a complete body the steampipe covers were installed.

Under the tanks the balance pipes were added followed by the rear supports for the tanks. I am unhappy with this aspect of the build as there is are considerable gaps between the tank supports and the balance pipe castings.

This photo of 80079 shows there are spaces between the three fittings but I can’t live with the gaps I have so they will have to be addressed before going any further with this area.

Work will continue with detailing the manifold adding pipework and the steam heat valve. On the smokebox the ejector and blower have to be added as well as the dome, chimney and smokebox door. Lots to do before returning to the frames.

Once the Standard Tank is nearing completion I will start work on a Taff Vale Models Cambrian 2-4-0 to be followed by A Finney7 West Country. The Lord Nelson is still on ice.

, the platform etch put in place and it was then held firmly in place by the coal space unit prior to soldering up.

, the platform etch put in place and it was then held firmly in place by the coal space unit prior to soldering up.