As alluded to in the previous post but 1 - a little teaser for the next project. Something I hoped was a quick one to get my modelling mojo back and one I've wanted to do for a while.

So yes the next project is a

Walsworth models Y1/3 kit. There have been a few builds posted online so I'm not proposing a step by step instruction. However as usual I never seem to be able to build any kit straight out of the box, so in my usual inimitable way I've deviated from the usual instructions and I'll post the differences.

We had quite a nice little discussion a few years ago when

@Sandy Harper was documenting a Y1/1 build from Walsworth models.

Walsworth Models Sentinel Y1 8400 . So the Y1/3 build is very similar but I'll come back to that in a minute.

On initial look at the kit I tackled the chassis first. As supplied it's a single etch be folded up with brass bushes to solder in for the axles.

View attachment 150268

Unfortunately my preference is for a sprung chassis - so some tweaks were going to be necessary. However this then causes a problem in working out how to mount the motor and gearbox. In the kit it's hung off one of the axles and then there is a delrin chain drive to the second axle so it makes the springing arrangement interesting as the motor and gearbox then needs to float a bit. I spent a few days mulling over how to work it when I remembered my comment in Sandy's thread and a potential solution started to develop.

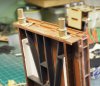

In the prototype the engine is mounted centrally, the Sentinel type designation is CE for central engine underneath which is a gearbox. There is then a chain drive from each side of the gearbox to each axle. So in reality there is no chain link from axle to axle [ that arrangement is in the DEDG engines] they are both driven from the gearbox. So my cunning plan is to mount the motor and gearbox vertically and centrally in the chassis and drive the axles from the central location. Hence building the gearbox with delrin gears on both sides to drive each axle, I also managed to open out the holes to use miniature ball races rather than plain bushes. The purposes of the outer shroud will become evident in the next few photos.

View attachment 150269

My preference for springing is fully floating springs rather than compensation so it was trying to work out to arrange a system of continuous springy beams (CSB) for the suspension. The other issue was to work out how to keep the delrin chain at the same tension during movement of the axles. If I simply enlarged the axle holes to fit horn blocks up and down then there would be a small, but realistically infinitesimal small change in length from the gearbox to the axles.

So my solution has been to make up some lever arms that pivot from the miniature ball race and hold the axles at the correct spacing. The next epiphany was arranging the fulcrum point for the CSB. Normally these are aligned directly above the axle centre line but I soon realised that being a simple 0-4-0 then there was no reason why the pivot points couldn't be arranged outboard of the axle centre line. Hence the arms below, when cutting out the arms I cut a slot in the outer section, folded it back on itself and twisted the top bit to provide the fulcrum point.

View attachment 150271

So as illustrated below these arms locate over the ball races and the gearbox shroud then fits around the outside to stop the arms dropping off. If you look closely on the shroud the little tab that is folded inboard, below the ball race hole, has a small hole drilled in it. This provides the central fulcrum point for the CSB.

View attachment 150272

So fitting it all together I have ended up with this sub unit - a little sprung arm 0-4-0 chassis.

View attachment 150273

View attachment 150275

So the next task is to work out how to modify the chassis to accommodate this sprung unit.

Dare we hope that a SITREP on the Hudswell railcar, last seen in Sep 2017 in Vauxhall green and with all its glazing still intact, might appear?

Dare we hope that a SITREP on the Hudswell railcar, last seen in Sep 2017 in Vauxhall green and with all its glazing still intact, might appear?