adrian

Flying Squad

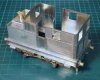

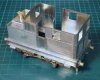

Next little update. The top plate was fitted to the tank area, this was just a flat sheet but from the drawing it looked like the water tank in the middle was raised so this was cut and bent from a bit of nickel-silver sheet. The cab doors and rear ventilation plates fitted. Something was slightly awry on bending the main cab sheets in that the door opening on the left hand side was spot on but on the right hand side it was ever so slightly wider such that there is a gap between the door and the frame. Rather than try to adjust things as it's barely noticeable I opted for having the door closed on the left hand side and open on the right hand side!

Next detail was going to be the window frames but I hit another slight hiccup. First - although there are 6 windows on the loco on the etch there are only 4 sliding frames. Not too much of a problem as the prototype photos rarely show all windows closed or partly closed, usually a couple are fully open, so I could make do with 4. Unfortunately when cut out and placed behind the opening it seems there is a size difference between the sliding unit and the frame and there is a noticeable gap.

Nothing for it but I'm going to have to make some new sliding units, might as well make 6 whilst I'm at it!

Then I got side tracked - the latest Guild Gazette dropped through the door. I have been considering dipping my toes into the DCC world and reading the review of the rolling road I thought one such item would be very useful/essential for setting up DCC. Then I saw the price £150

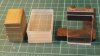

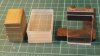

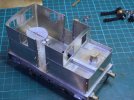

- the latest Guild Gazette dropped through the door. I have been considering dipping my toes into the DCC world and reading the review of the rolling road I thought one such item would be very useful/essential for setting up DCC. Then I saw the price £150  and thought that's the price of a coach kit or equivalent. So I raided my offcuts box to see if there was anything useable, some 1/8" brass strip and some 5mm perspex was dutifully cut up. I then made a little drilling jig to help things along.

and thought that's the price of a coach kit or equivalent. So I raided my offcuts box to see if there was anything useable, some 1/8" brass strip and some 5mm perspex was dutifully cut up. I then made a little drilling jig to help things along.

A few 6BA tapped holes and bushed 9x3x3 ball races later and it seemed to work okay. I've got some slightly shorter 6BA screws on order to tidy it up and need some brass strip to make up a static cradle for an non-powered tender or bogie - that and another 48 holes to tap to keep me busy.

Next detail was going to be the window frames but I hit another slight hiccup. First - although there are 6 windows on the loco on the etch there are only 4 sliding frames. Not too much of a problem as the prototype photos rarely show all windows closed or partly closed, usually a couple are fully open, so I could make do with 4. Unfortunately when cut out and placed behind the opening it seems there is a size difference between the sliding unit and the frame and there is a noticeable gap.

Nothing for it but I'm going to have to make some new sliding units, might as well make 6 whilst I'm at it!

Then I got side tracked

- the latest Guild Gazette dropped through the door. I have been considering dipping my toes into the DCC world and reading the review of the rolling road I thought one such item would be very useful/essential for setting up DCC. Then I saw the price £150

- the latest Guild Gazette dropped through the door. I have been considering dipping my toes into the DCC world and reading the review of the rolling road I thought one such item would be very useful/essential for setting up DCC. Then I saw the price £150  and thought that's the price of a coach kit or equivalent. So I raided my offcuts box to see if there was anything useable, some 1/8" brass strip and some 5mm perspex was dutifully cut up. I then made a little drilling jig to help things along.

and thought that's the price of a coach kit or equivalent. So I raided my offcuts box to see if there was anything useable, some 1/8" brass strip and some 5mm perspex was dutifully cut up. I then made a little drilling jig to help things along.

A few 6BA tapped holes and bushed 9x3x3 ball races later and it seemed to work okay. I've got some slightly shorter 6BA screws on order to tidy it up and need some brass strip to make up a static cradle for an non-powered tender or bogie - that and another 48 holes to tap to keep me busy.

no dual gauge!

no dual gauge!