You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brushs Laser Cutting and 3d Printing workbench

- Thread starter BrushType4

- Start date

Lancastrian

Western Thunderer

I started building one in plastic-card a few years ago, but got side-tracked with other more pressing projects. I must get on with the window frames for the operating floor. That looks really good though

Ian

Ian

Peter Insole

Western Thunderer

Champion Phil! That is a superb beast!

Well done for cracking the curves and that particularly problematic cone on the roof awning!

Going to need a concrete mixer now....?!

Pete.

Well done for cracking the curves and that particularly problematic cone on the roof awning!

Going to need a concrete mixer now....?!

Pete.

BrushType4

Western Thunderer

So do I.I hope Alan likes it!

John

Osgood

Western Thunderer

....... and that particularly problematic cone on the roof awning!.....

Oh, I see now how he's done that

BrushType4

Western Thunderer

Oh, I see now how he's done that

Tony, it is the best I could do. It can be improved with filler but I hope that falls within the clients scope

Osgood

Western Thunderer

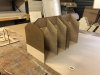

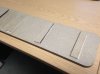

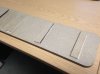

Phil cut a kit of parts for a house name sign which I am making as a festive present for friends who have recently acquired a holiday lodge overlooking the Severn Valley Railway (think of my task as therapy to counter my jealousy), and asked me to put up a shot or two of the assembly.

The waterproof MDF (medium-density fibreboard, Mick ) precision components were collected last week , and it was a real pleasure to assemble them into something resembling a nameplate.

) precision components were collected last week , and it was a real pleasure to assemble them into something resembling a nameplate.

I had asked Phil to let me have the waste piece so I could use it as a template for glueing the letters - I needn't have bothered, as it proved much easier to align them with the letter outlines which Phil had lasered onto the main board. A clamped straight edge made it even more so.

To avoid drilling mounting holes I cut some spacing strips from the spare fret and glued to the rear, allowing the plate to be fastened to its synthetic wood wall by 12mm automotive double-sided tape (as in number plates/body trim). The main benefit of the spacers is to prevent water becoming trapped between wall and plate - not that I don't trust the claims made for waterproof MDF.....

Waterproof PVA wood glue was spread thinly over a sheet of glass and each letter dunked on to give a uniform thin coat. I had ideas of a heavy application so that excess would be squeezed out on positioning which, with the aid of a rounded tool, could be formed into a fillet as in best foundry casting practice. This gave inconsistent and messy results, so plan B was adopted (clean off any excess glue and rely on a thick background paint application for the radius). No doubt there is a suitable filler which could be applied if one wished to create a proper fillet.

Two coats of automotive spray primer are currently being followed by Halfords Nissan Gold to simulate brass, leaving just a brush coat of Tractol British racing green synthetic enamel background colour to go on tomorrow.

Thanks to Phil for making this an easy, pleasant task

The waterproof MDF (medium-density fibreboard, Mick

) precision components were collected last week , and it was a real pleasure to assemble them into something resembling a nameplate.

) precision components were collected last week , and it was a real pleasure to assemble them into something resembling a nameplate.I had asked Phil to let me have the waste piece so I could use it as a template for glueing the letters - I needn't have bothered, as it proved much easier to align them with the letter outlines which Phil had lasered onto the main board. A clamped straight edge made it even more so.

To avoid drilling mounting holes I cut some spacing strips from the spare fret and glued to the rear, allowing the plate to be fastened to its synthetic wood wall by 12mm automotive double-sided tape (as in number plates/body trim). The main benefit of the spacers is to prevent water becoming trapped between wall and plate - not that I don't trust the claims made for waterproof MDF.....

Waterproof PVA wood glue was spread thinly over a sheet of glass and each letter dunked on to give a uniform thin coat. I had ideas of a heavy application so that excess would be squeezed out on positioning which, with the aid of a rounded tool, could be formed into a fillet as in best foundry casting practice. This gave inconsistent and messy results, so plan B was adopted (clean off any excess glue and rely on a thick background paint application for the radius). No doubt there is a suitable filler which could be applied if one wished to create a proper fillet.

Two coats of automotive spray primer are currently being followed by Halfords Nissan Gold to simulate brass, leaving just a brush coat of Tractol British racing green synthetic enamel background colour to go on tomorrow.

Thanks to Phil for making this an easy, pleasant task

BrushType4

Western Thunderer

Don't look bad...

Osgood

Western Thunderer

One observation which will hopefully guide me when I get round to assembling some MDF buildings was that the laser cutting action does a wonderful job of sealing the fibrous 'end grain' of the material - the sawn and sanded areas of the packers where I had cut them out soak up paint like tissue. The sprayed primer, whilst looking effective, had failed to seal these parts.

BrushType4

Western Thunderer

BrushType4

Western Thunderer

Carrying on with the Southern theme, a Exmouth Junction produced footbridge. Thanks to @Peter Insole for copies of his drawings and the nice day out we had photographing a similar example in Essex.

Last edited:

BrushType4

Western Thunderer

I had the pleasure of dropping off the recent signal box commission this morning. It will be disappearing to Bristol in the new year to be built and painted but before then it was put in position in its new home.

This box weighs in at an mighty 720mm long (28 inches) but it fits into the layout without looking imposing at all. It helps that the layouts owner had excellent vision and space to build beautiful sweeping track work.

A signal man is just checking the view before the final fit out guys turn up.

A small realignment of the p/way is required.

The Southern footbridge I'm working on will need to span at least six roads on this layout and I'm looking forward to seeing that in place too.

This box weighs in at an mighty 720mm long (28 inches) but it fits into the layout without looking imposing at all. It helps that the layouts owner had excellent vision and space to build beautiful sweeping track work.

A signal man is just checking the view before the final fit out guys turn up.

A small realignment of the p/way is required.

The Southern footbridge I'm working on will need to span at least six roads on this layout and I'm looking forward to seeing that in place too.