Pencarrow

Western Thunderer

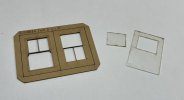

There seems to some debate elsewhere as to the authenticity of the model and the type of cladding portrayed.

So a side by side view here. Have we captured this as well as could be expected in a model or have we got it wrong?

View attachment 183488View attachment 183489

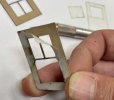

All looks spot on to me, particularly the cladding and roof beams. The only variance I can see, after looking at the photos for a while, regards the diagonal bracing and associated horizontal stiffener beam.

In the top photo the diagonals join the columns below floor level and in the model they join above floor level. I also wonder if the real top joint is slightly further down the column too but the photo isn't that clear. Overall this/these different joint locations have the effect of lowering the relative position of the point where the diagonals cross, and the horizontal is also therefore lower.

The civil engineer in me also notes that the diagonals and horizontal in the model are solid box section whereas they should be L section. Obviously a compromise given it's a laser cut kit, and a hardly noticeable variance which gives the builder opportunity to further enhance the kit with plastic or brass L section should they wish.

Other than those minor points I can't see anything for the armchair pundits to moan about, an absolutely excellent rendition of a workaday subject.

Last edited: